Drilling machine sound wave power head eccentric vibration generating device

A vibration generation and power head technology, applied in the field of power heads, can solve the problems of poor vibration stability and low vibration transmission efficiency, and achieve the effects of small vibration inertia, high vibration transmission efficiency, and ensuring installation position accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

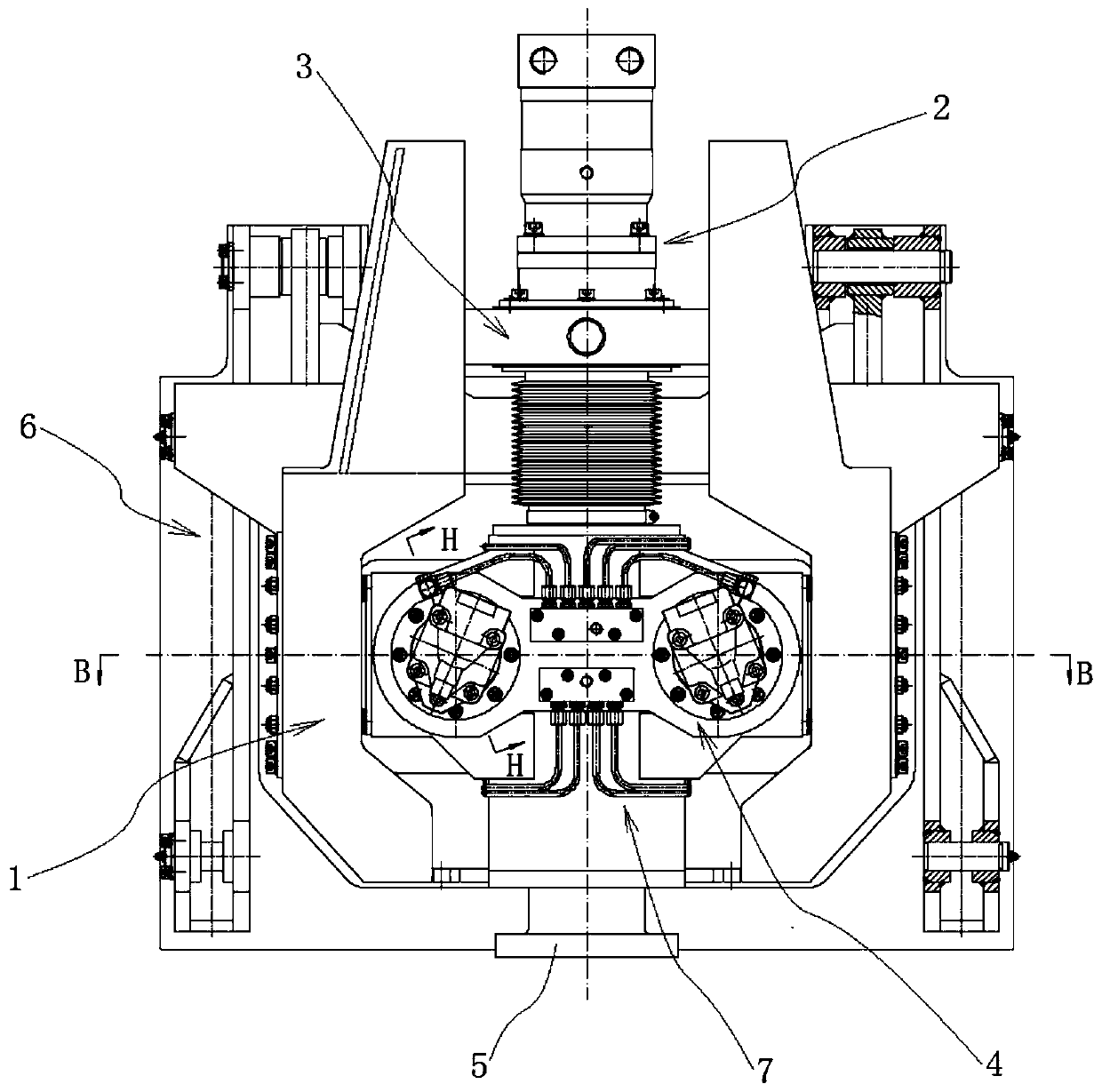

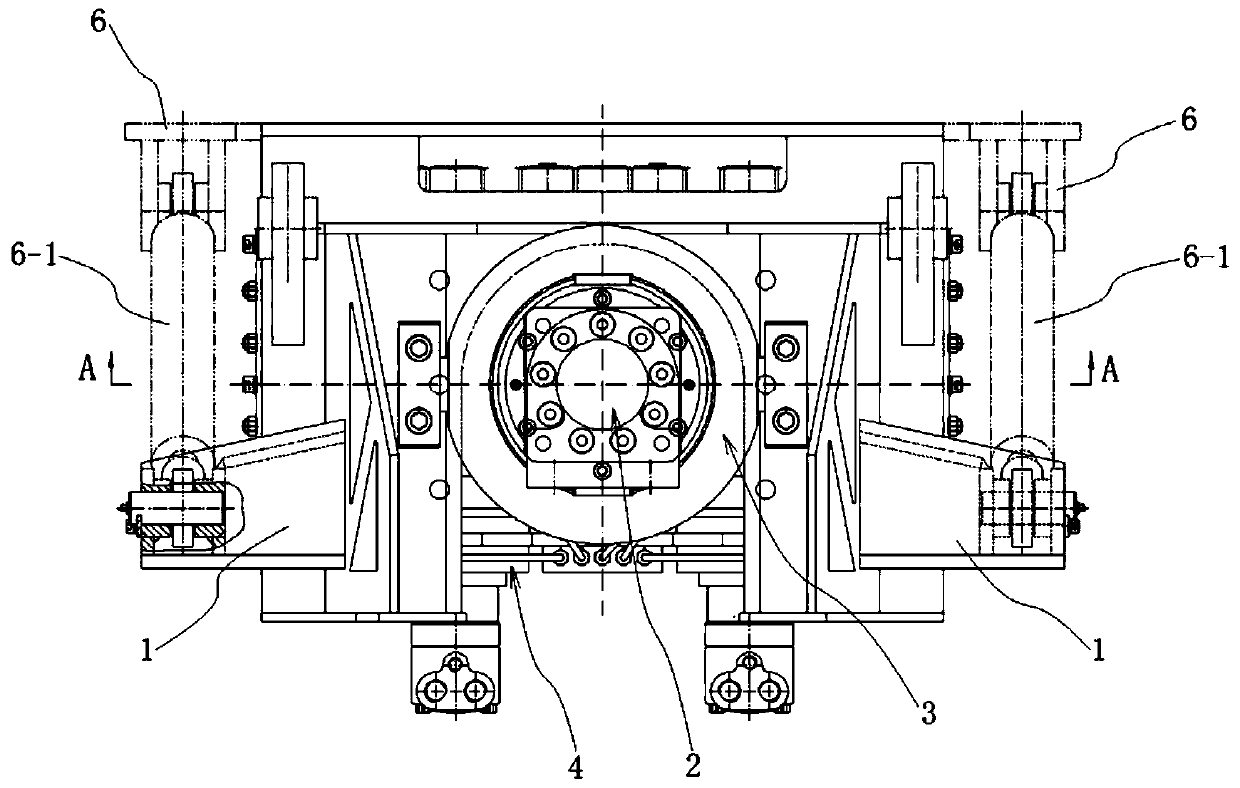

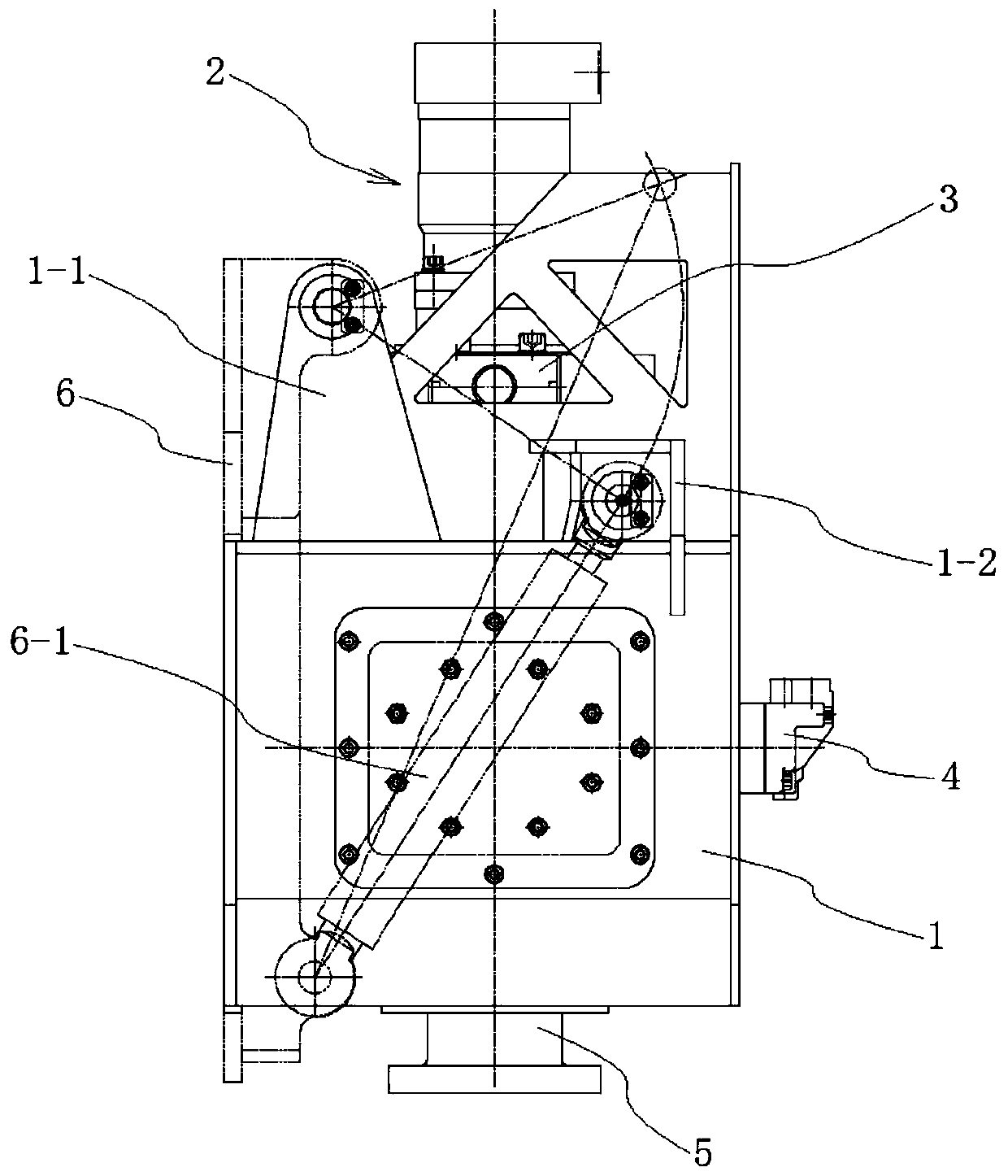

[0055] combine Figure 1 to Figure 5 As shown, an eccentric vibration generating device of a drilling rig sonic power head in this embodiment includes a main frame 1, a main shaft rotating mechanism 2 and a main shaft vibrating mechanism 4, and the main frame 1 is used as a supporting part of the whole sonic power head for installing the main shaft rotating Mechanism 2 and spindle vibration mechanism 4, wherein: spindle rotation mechanism 2 includes spindle hydraulic motor 2-1 and spindle 2-7, spindle hydraulic motor 2-1 is installed on the upper part of main frame 1, and the output of spindle hydraulic motor 2-1 The shaft and the main shaft 2-7 are connected by a spline structure transmission to drive the main shaft 2-7 to rotate and allow the main shaft 2-7 to move up and down in the axial direction; the main shaft vibration mechanism 4 includes a main shaft box 4-1 and a vibration isolator 4 -2 and two sets of symmetrically arranged eccentric vibration mechanisms, the main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com