Shield tunnel segment and manufacturing method thereof

A shield tunnel segment and segment technology, which is used in tunnels, tunnel linings, and earth-moving drilling and mining, etc., can solve the problems of poor overall efficiency, long cycle, and occupation of large factory sites, saving pool sites and improving quality. and strength performance control, the effect of large practical economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

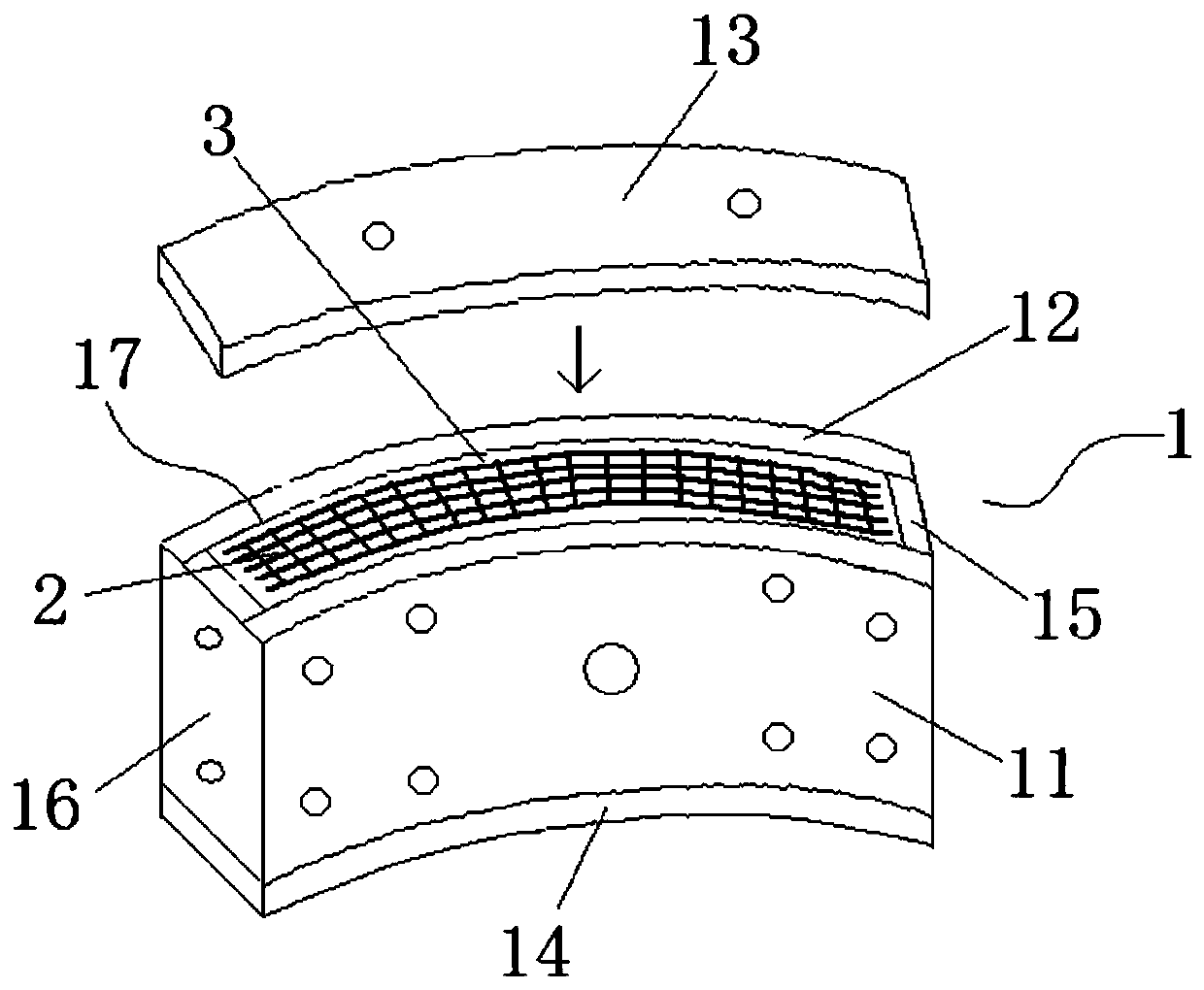

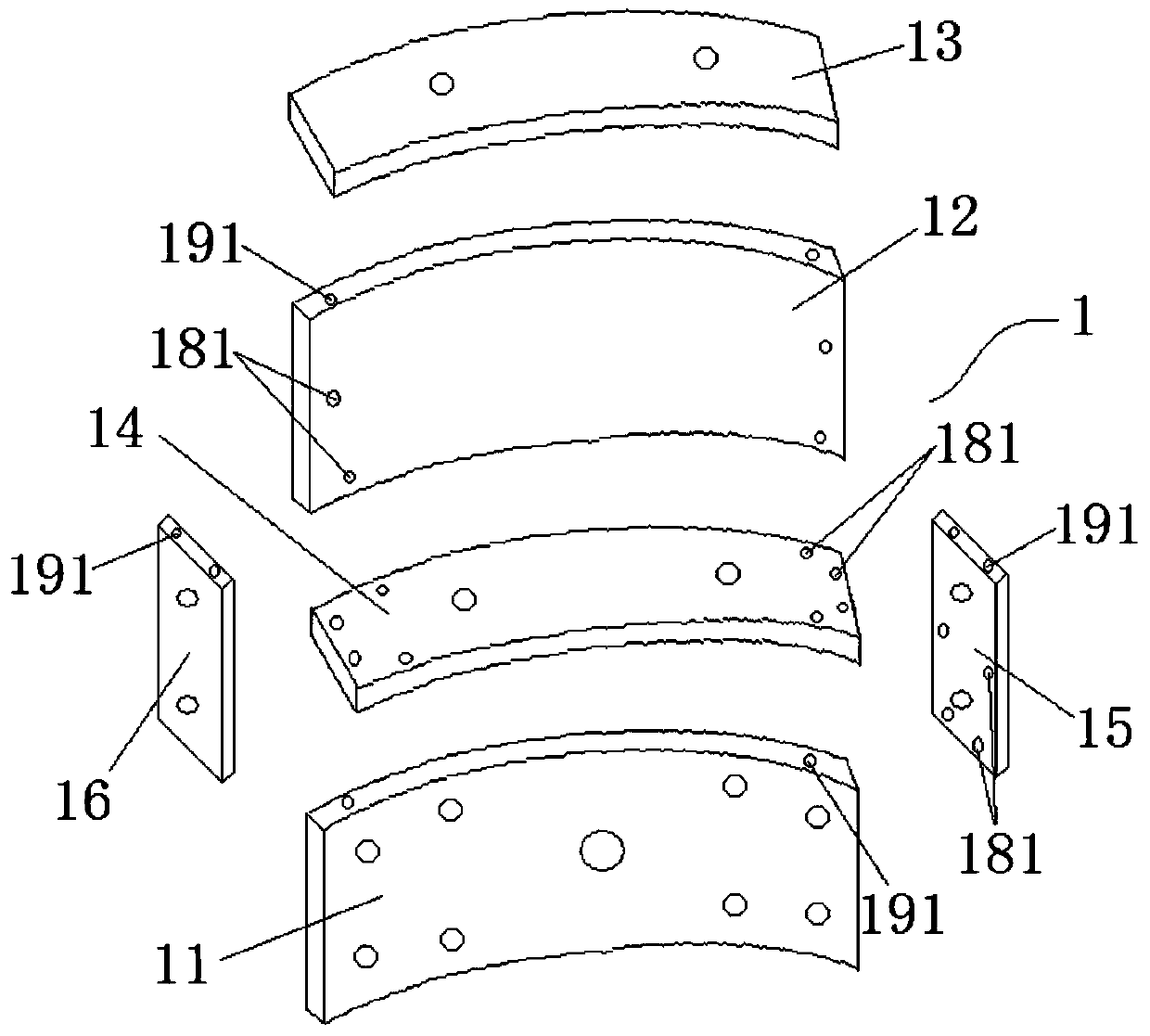

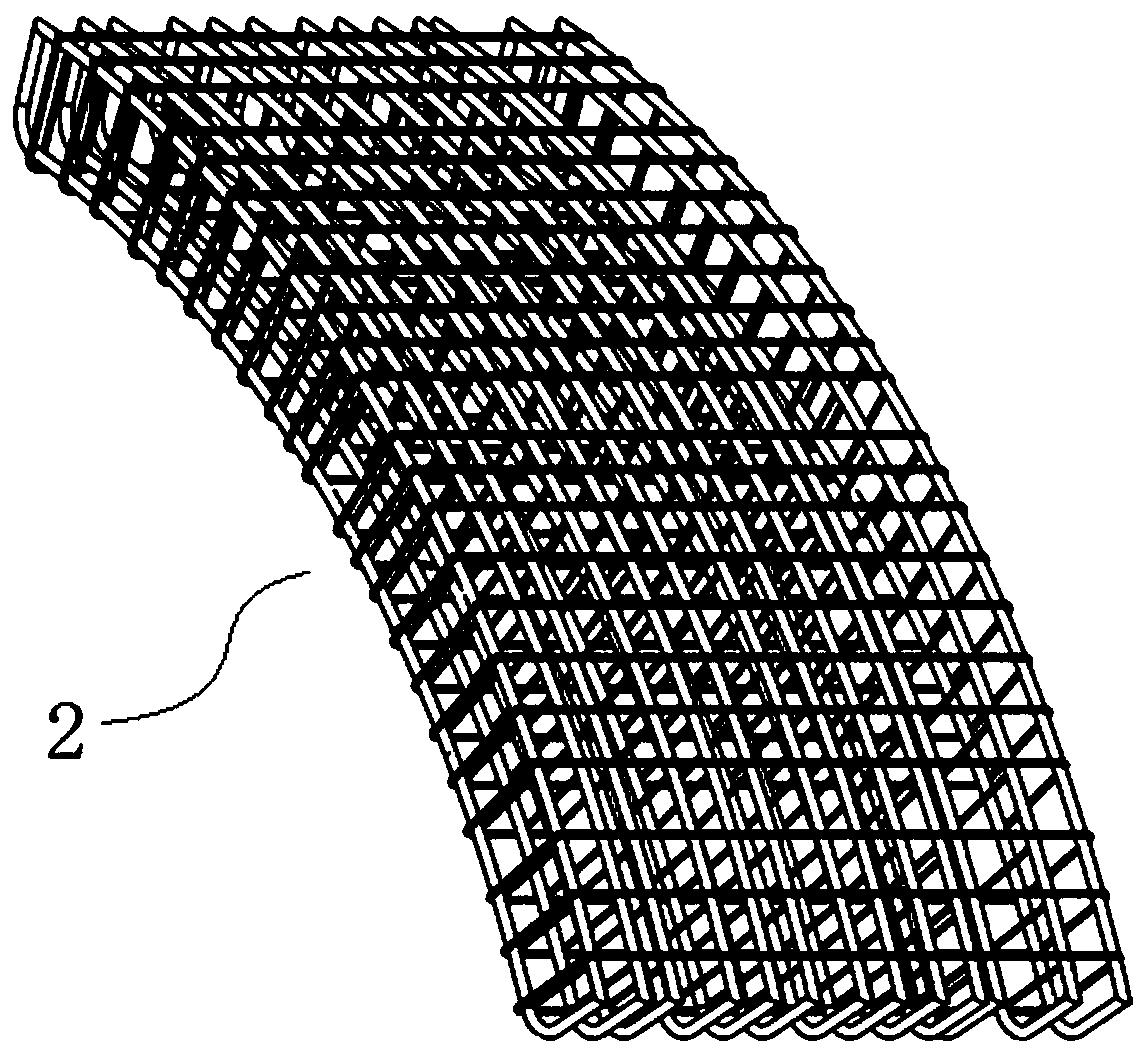

[0045] Such as Figure 1-7 As shown, in this embodiment, a shield tunnel segment is provided, which mainly includes a segment shell 1 and a steel cage 2 arranged in the segment shell 1, and the steel cage 2 is fixedly arranged by pouring concrete 3. In the tube shell 1.

[0046] Specifically, the tube piece housing 1 is composed of a front wall piece 11, a rear wall piece 12, an upper wall piece 13, a lower wall piece 14, a left wall piece 15 and a right wall piece 16. The front wall piece 11, The rear wall piece 12, the upper wall piece 13, the lower wall piece 14, the left wall piece 15 and the right wall piece 16 are all made of high performance concrete (HPC) or ultra high performance concrete (UHPC); wherein, the front wall piece 11. Any five of the rear wall piece 12, the upper wall piece 13, the lower wall piece 14, the left wall piece 15 and the right wall piece 16 are assembled to form a receiving cavity 17 with a unique opening, and the remaining one is detachably arra...

Embodiment 2

[0062] The same parts as in Example 1 will not be repeated, such as Figure 8 As shown, this embodiment provides a shield tunnel segment, which also includes a segment shell 1 and a reinforcement cage 2 arranged in the segment shell 1. The reinforcement cage 2 is fixedly arranged by pouring concrete 3 In the tube shell 1.

[0063] Specifically, the tube piece housing 1 in this embodiment is annular, and is composed of an inner wall piece 51, an outer wall piece 52, a first side wall piece 53, and a second side wall piece 54; the inner wall piece 51 Any three of the outer wall piece 52, the first side wall piece 53 and the second side wall piece 54 are assembled to form a receiving cavity 17 with a unique opening, and the remaining piece is detachably arranged at the opening of the receiving cavity 17 to close The containing cavity 17.

[0064] Further, the main difference between the manufacturing method of the tube shell in this embodiment and the tube shell in embodiment 1 is:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com