Air floating support system

A support system and air flotation technology, applied in the field of bearing structure, can solve the problems of small mass, poor capacity and small bearing capacity of suspended objects, and achieve the effect of increasing the suspension force, wide application range and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

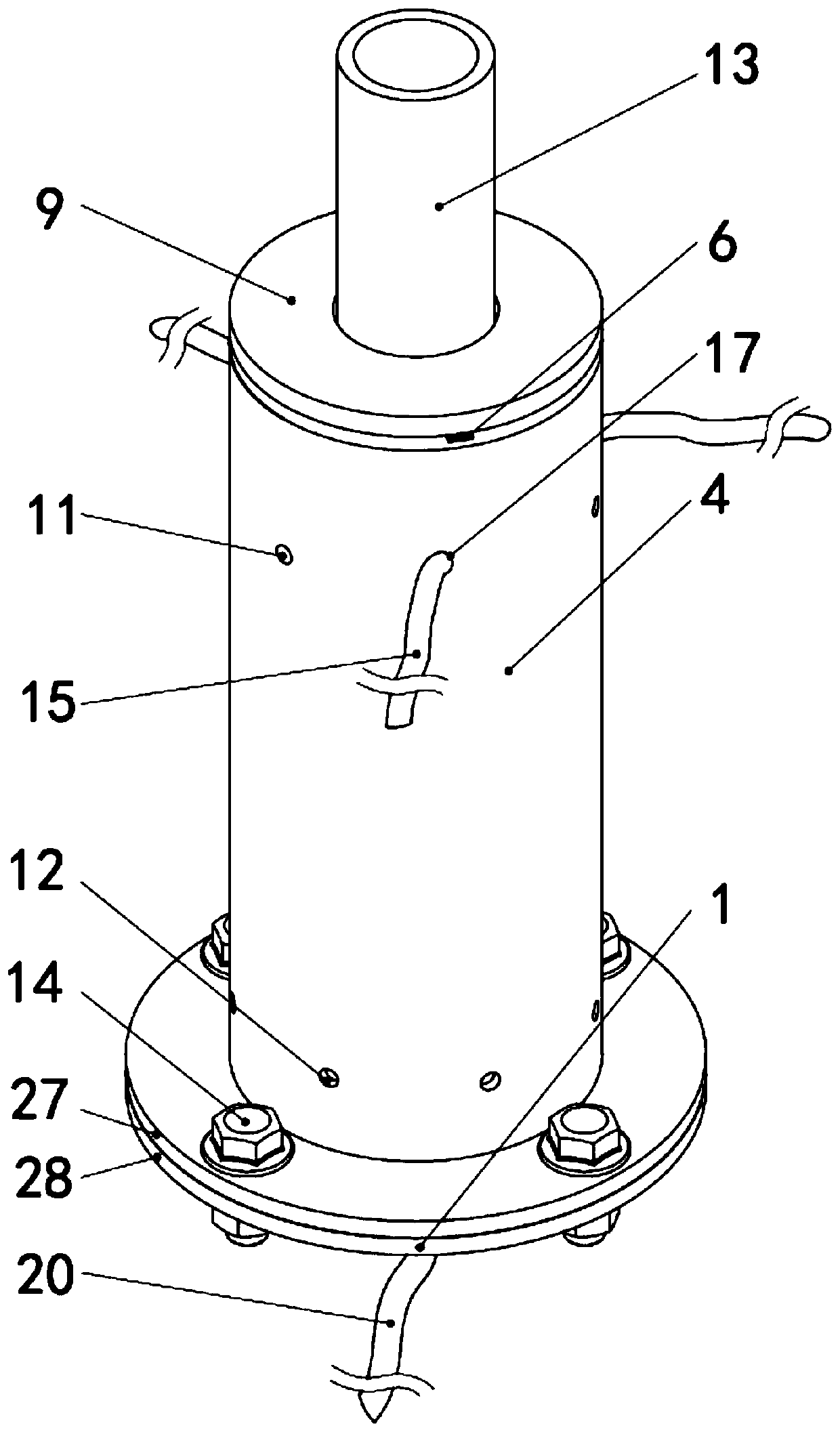

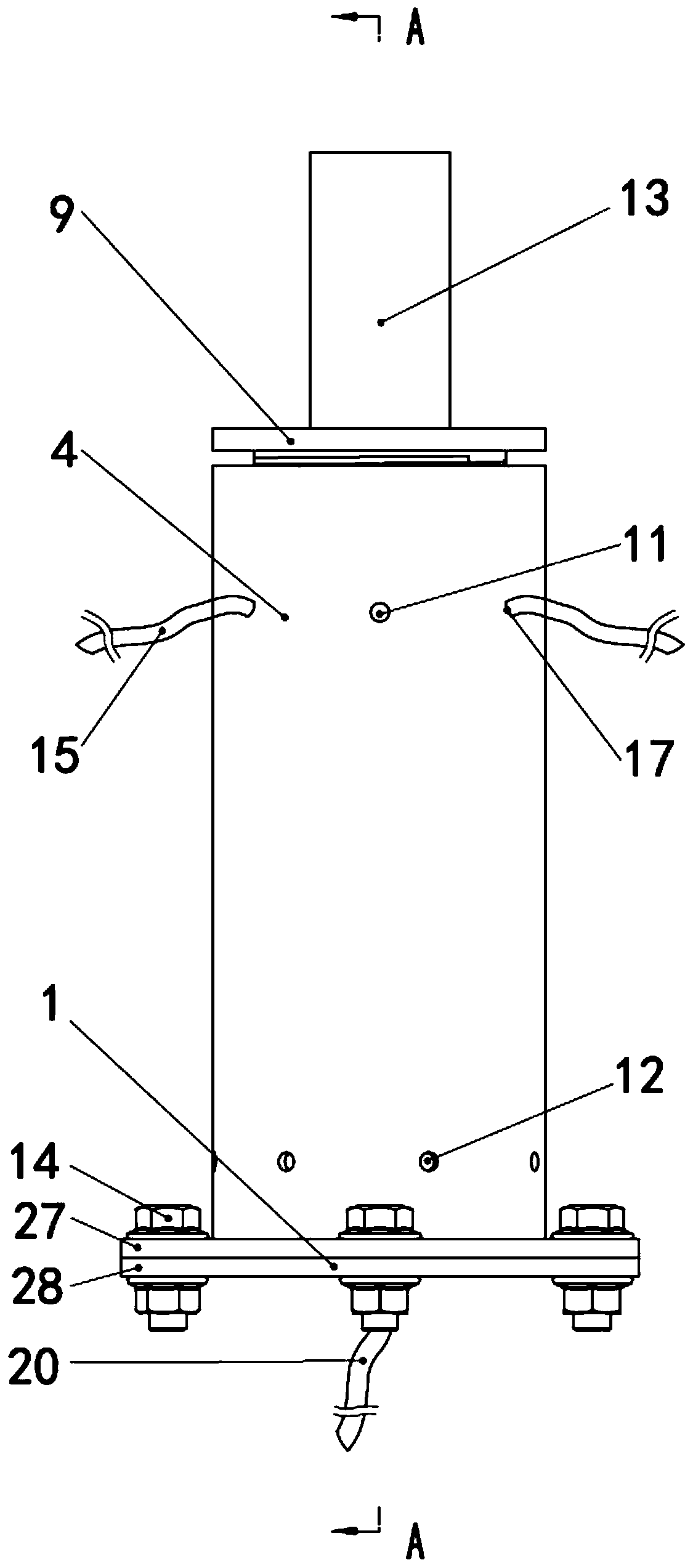

[0023] It can be seen from the accompanying drawings that the present invention uses piezoelectric ceramic materials to make radial and axial near-field ultrasonic levitation structures, and realizes the radial and axial free movement of the rotor through the mixed suspension of air flotation and near-field ultrasonic levitation. Contact stabilizer.

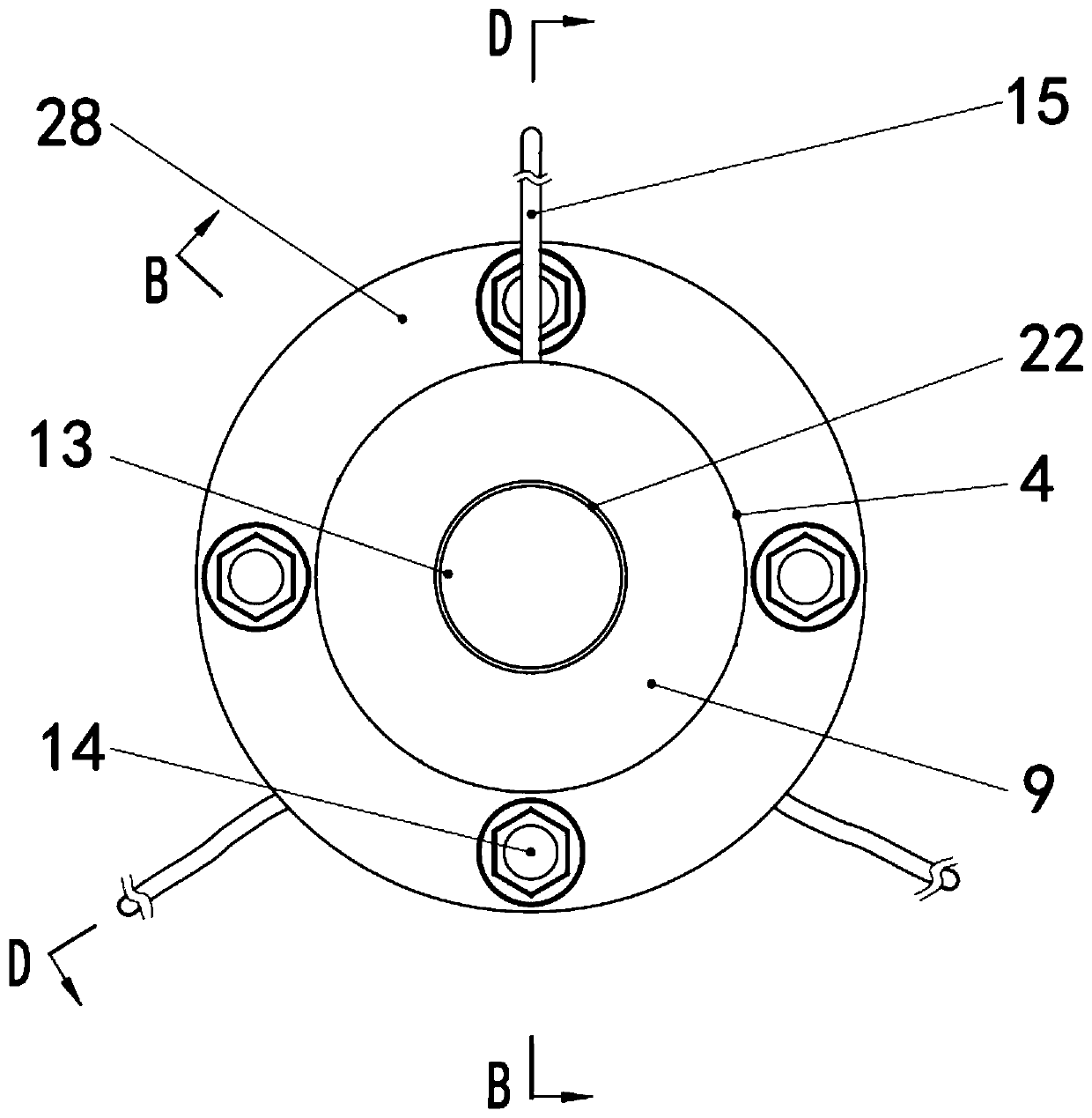

[0024] An air bearing system, characterized in that: a boss 24 with a shaft hole 5 is arranged above the inside of the shell 4, the inside of the shell 4 is divided into two parts by the boss 24, and the upper side of the boss 24 is an upper cavity 16, The lower side is the lower cavity 29 . The lower end of the shell 4 is provided with a flange 27, and a support base 1 with a flange 28 is provided below the flange 27. The flange 27 and the flange 28 are provided with through holes and are fixedly connected together by bolts 14. The upper cavity The inner wall of 16 is provided with the circumferential positioning groove 6 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com