Gas density relay with simulation verification function and simulation verification method thereof

A technology of gas density and relay, applied in the field of electric power, can solve a lot of problems of manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

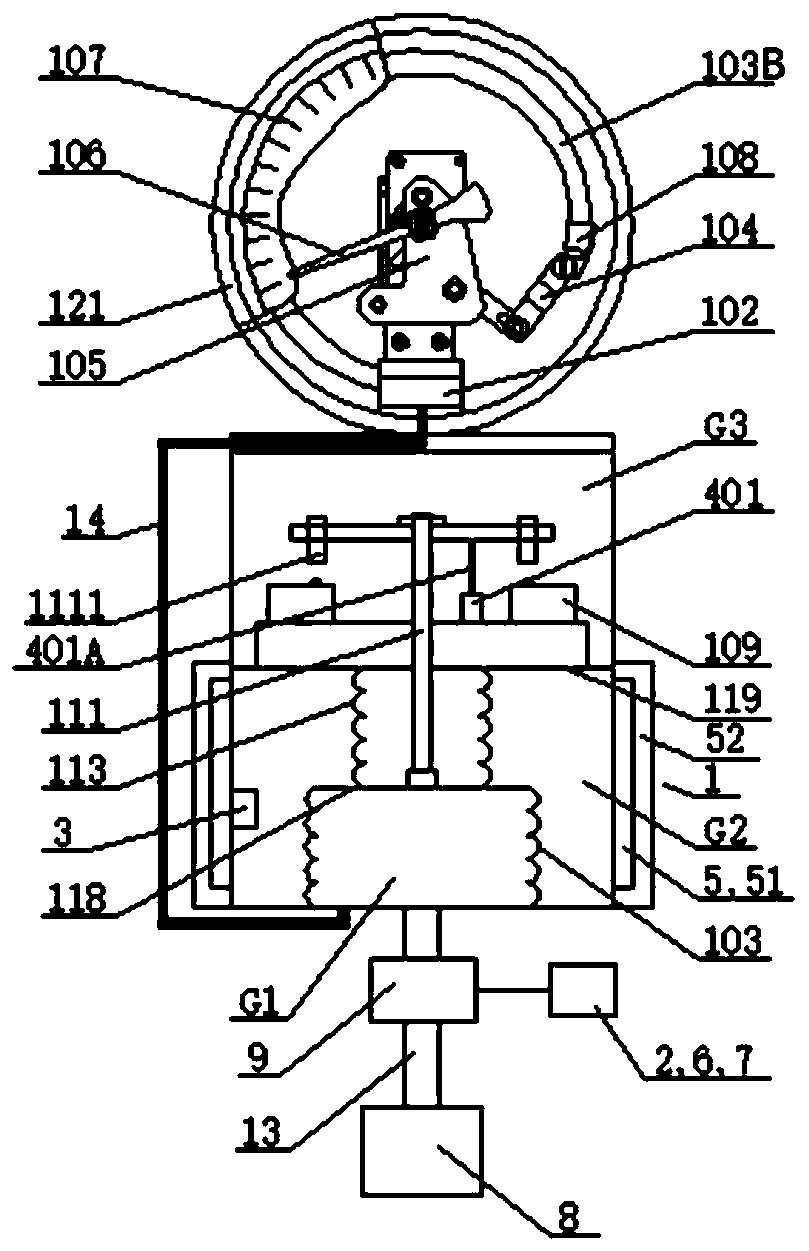

[0160] Such as figure 1 As shown, the embodiment of the present invention has a gas density relay or a gas density monitoring device with a simulation or virtual calibration function, including: a gas density relay body 1, a simulation reference signal unit (composed of a pressure sensor 2 and a temperature sensor 3), Drive the contact action mechanism, the online verification contact signal sampling unit 6, the intelligent control unit 7, the simulation verification signal unit, the multi-way connector 9 and the electrical equipment connector 13. Among them, the gas density relay body 1 , the pressure sensor 2 , the online verification contact signal sampling unit 6 and the intelligent control unit 7 are arranged on the multi-way joint 9 . The action mechanism for driving the contact is a temperature adjustment mechanism 5, which includes a heating element 51 and a heat preservation piece 52. The temperature sensor 3, the heating element 51 and the heat preservation piece 52 ...

Embodiment 2

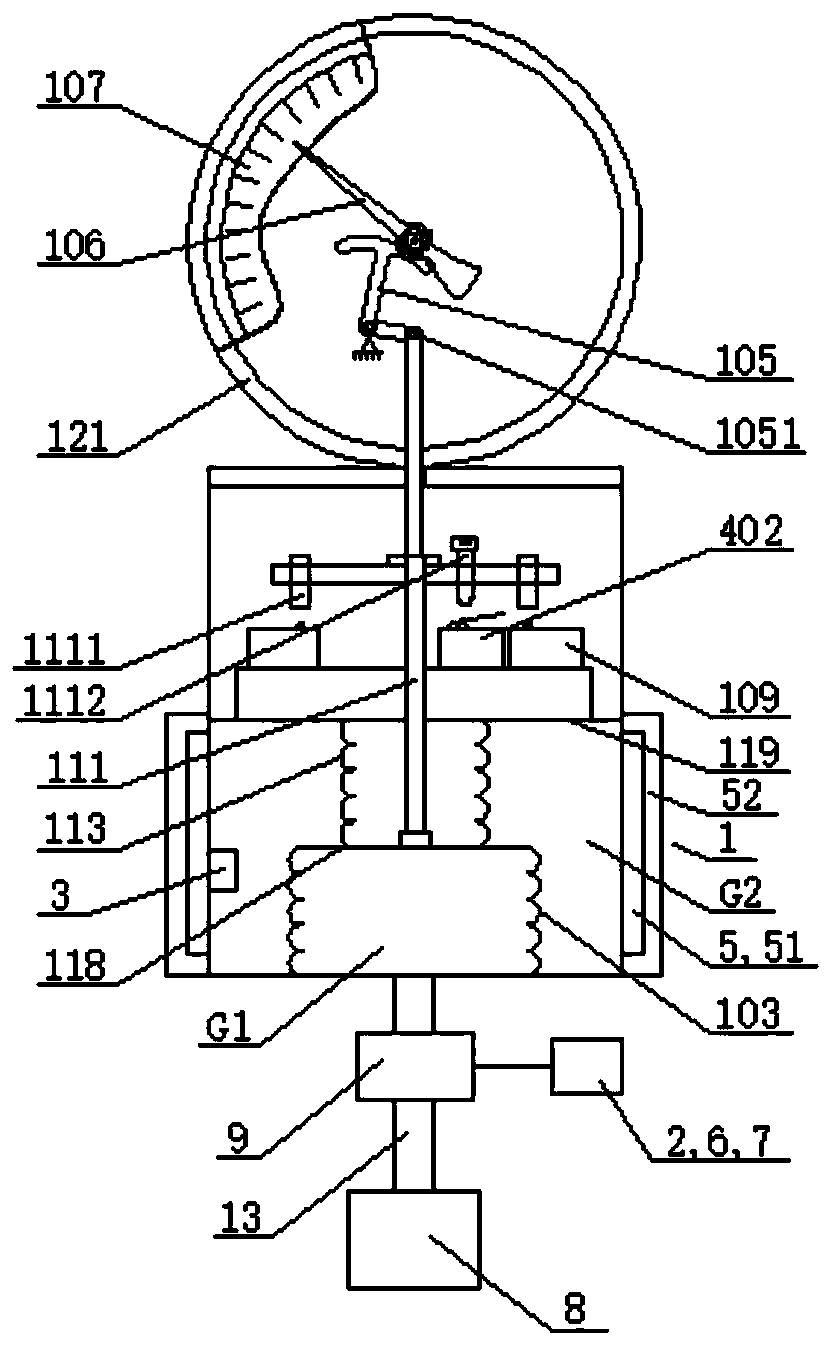

[0173] Such as figure 2 As shown, the second embodiment of the present invention has a gas density relay or a gas density monitoring device with a simulation or virtual calibration function, including: a gas density relay body 1, a simulation reference signal unit (composed of a pressure sensor 2 and a temperature sensor 3), Drive the contact action mechanism, the online verification contact signal sampling unit 6, the intelligent control unit 7, the simulation verification signal unit, the multi-way connector 9 and the electrical equipment connector 13. Among them, the gas density relay body 1 , the pressure sensor 2 , the online verification contact signal sampling unit 6 and the intelligent control unit 7 are arranged on the multi-way joint 9 . The actuating mechanism for driving the contact is a temperature adjustment mechanism 5, which includes a heating element 51 and a heat preservation piece 52, which are respectively arranged on the body 1 of the gas density relay. ...

Embodiment 3

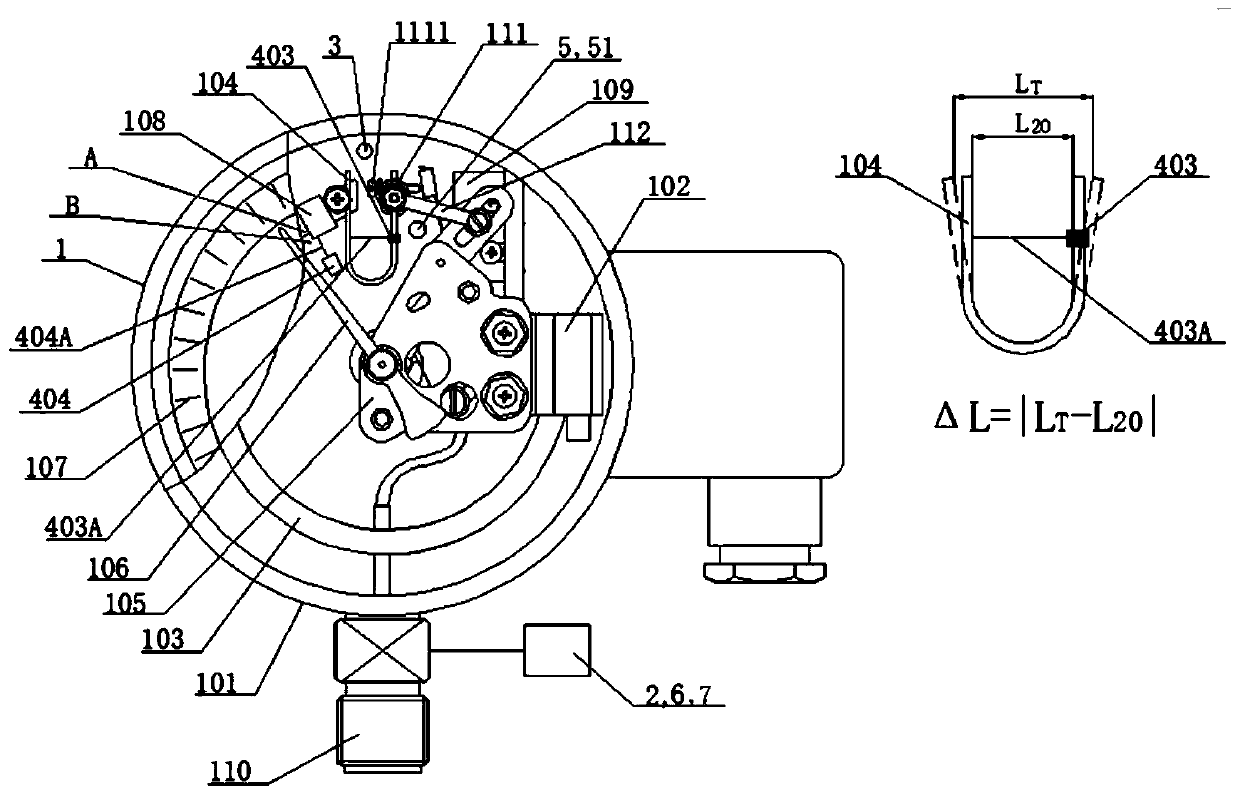

[0182] Such as image 3 As shown, a gas density relay or gas density monitoring device with a simulation verification function includes: a gas density relay body 1, a simulation reference signal unit (a gas density detection sensor, composed of a pressure sensor 2 and a temperature sensor 3), Drive the contact action mechanism 5, the online verification contact signal sampling unit 6, the intelligent control unit 7 and the simulation verification signal unit. Wherein, the simulation calibration signal unit includes two diagnostic sensors, respectively the first diagnostic sensor 403 and the second diagnostic sensor 404, all arranged in the housing 101 of the gas density relay body 1; the pressure sensor 2, the online calibration contact signal The sampling unit 6 and the intelligent control unit 7 are arranged on the connector 110 for connecting electrical equipment; the temperature sensor 3 is arranged in the casing 101 . On the gas path, the pressure sensor 2 of the gas den...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com