Embossed stainless steel pipe manufacturing device and embossed stainless steel pipe manufacturing method using the same

A stainless steel tube and manufacturing device technology, which is applied to the embossed stainless steel tube manufacturing device and the embossed stainless steel tube manufacturing field using the same, can solve the problem that the hardness of the embossed stainless steel plate increases, the poor embossed stainless steel tube, and the inability of the rolling mill to be curved and circularization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0103] Hereinafter, the technical configuration of the present invention will be described in detail with reference to the accompanying drawings.

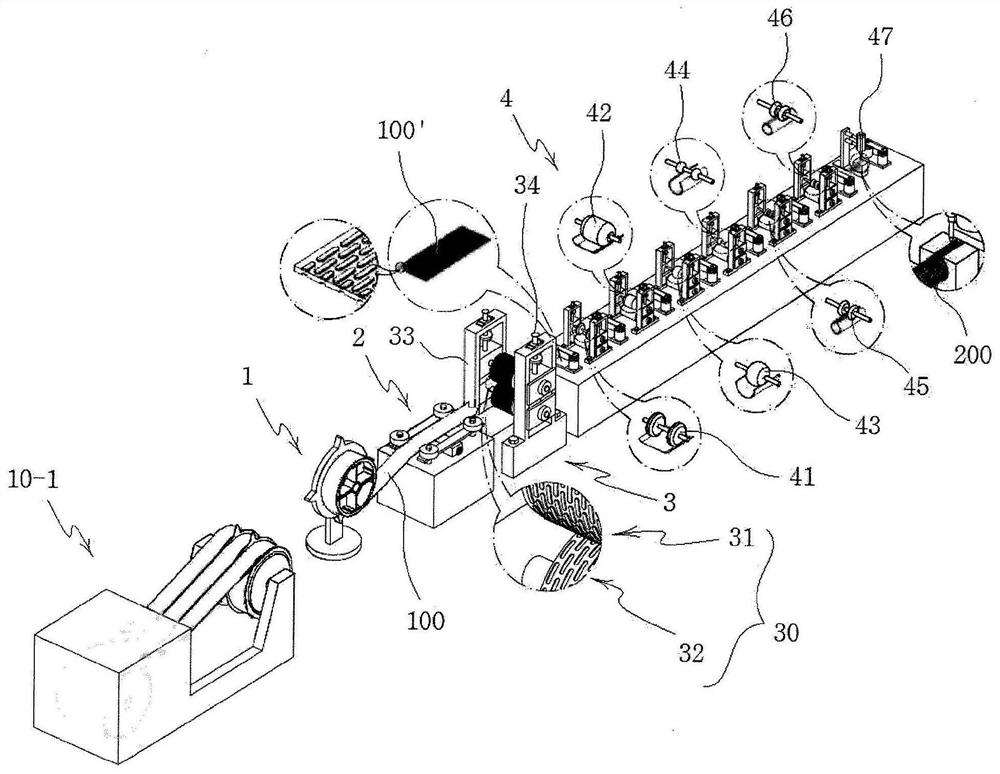

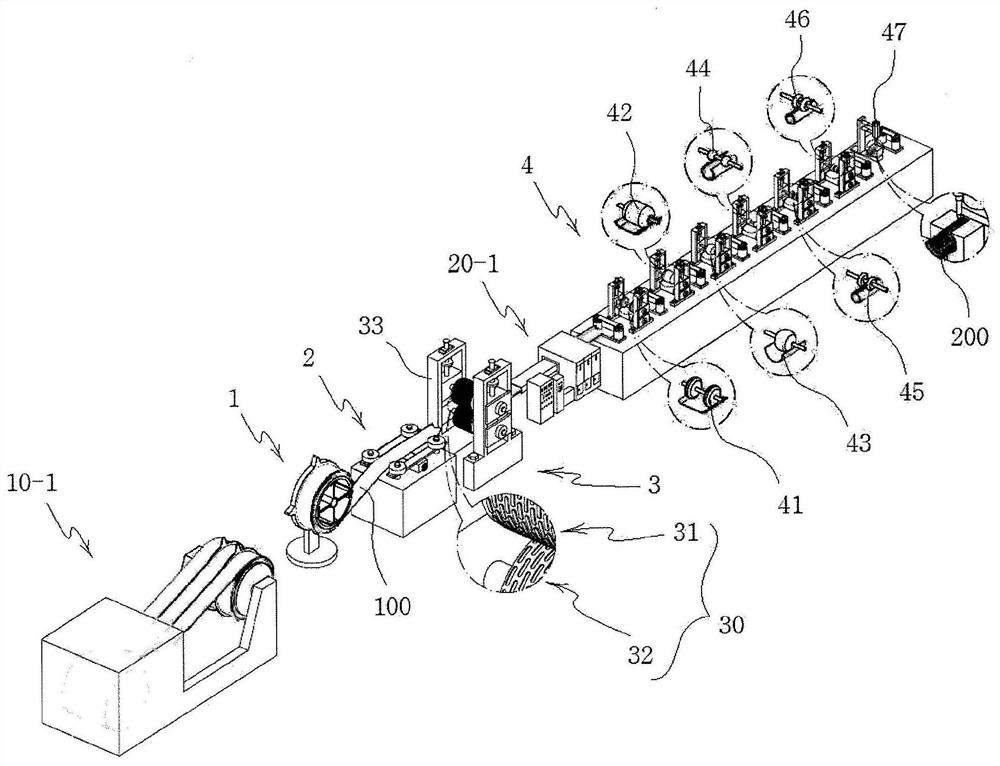

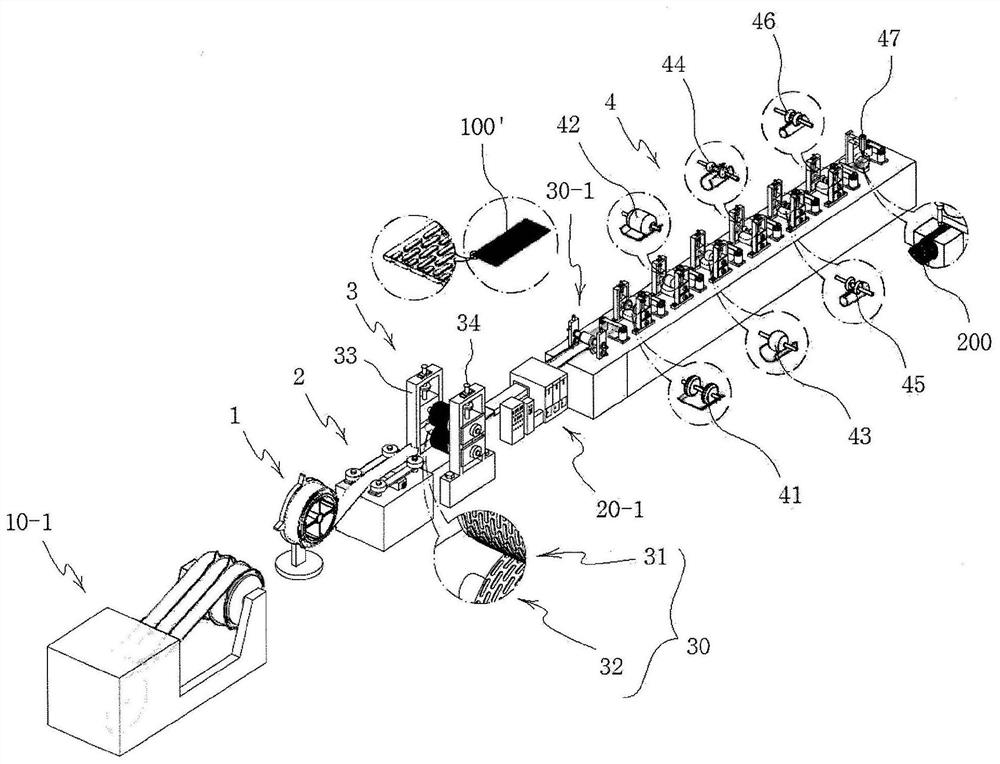

[0104] Figure 1 to Figure 3 The illustrated embossed stainless steel pipe manufacturing apparatus 1 relates to the embossed stainless steel pipe manufacturing apparatus 1 of the first to third embodiments, which are different according to additional embodiments configured.

[0105] figure 1 The embossed stainless steel pipe manufacturing device 1 of the first embodiment shown includes: an uncoiler 1 that provides a stainless steel flat plate 100;

[0106] The centering guide roller 2 guides the stainless steel plate 100 supplied by the uncoiler 1 to the embossing machine 3 at the rear end;

[0107] Embossing machine 3 carries out embossing treatment to the stainless steel plate 100 that supplies through above-mentioned centering guide roller 2, forms embossed stainless steel plate 100 ';

[0108] The pipe rolling machine 4 make...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com