Water-based extinguishing agent and preparation method thereof

A technology of fire extinguishing agent and water system, applied in fire protection equipment and other directions, can solve problems such as insufficient fire extinguishing performance, and achieve the effects of inhibiting heat transfer, increasing solution viscosity, and improving fire extinguishing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

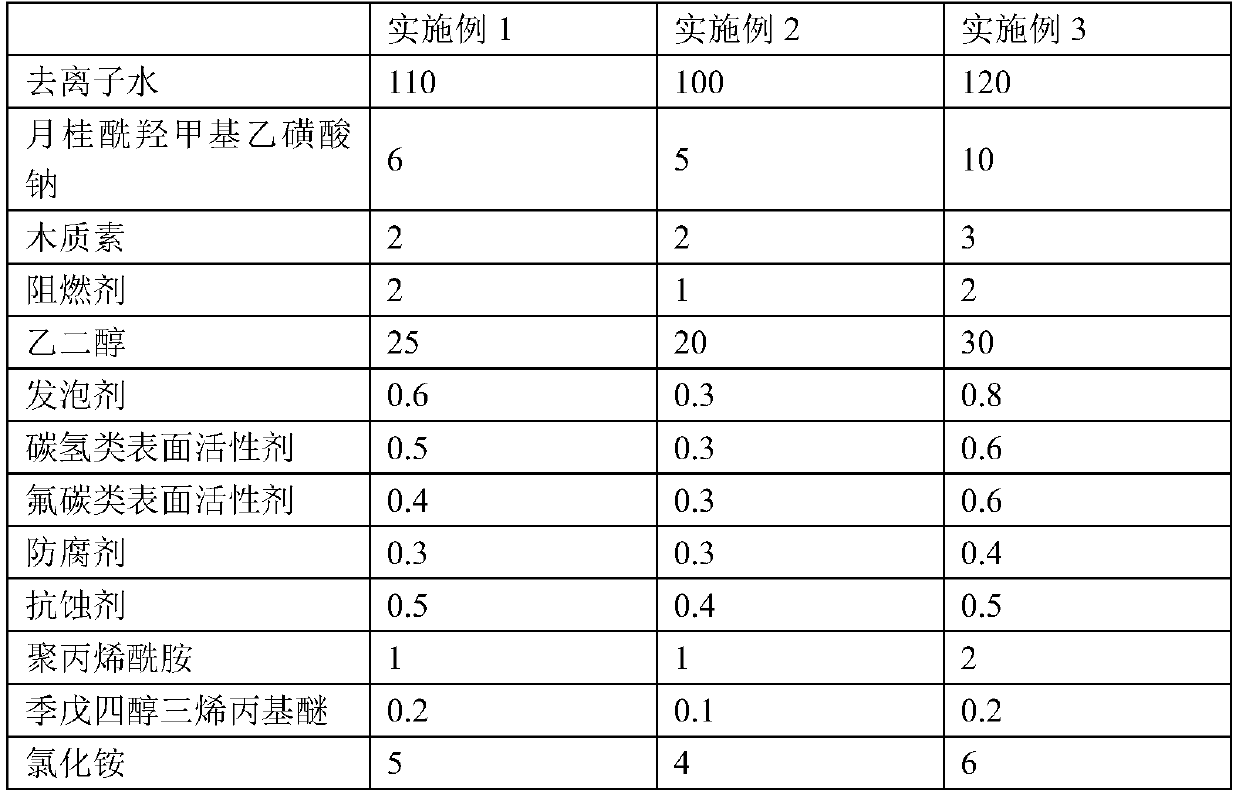

Embodiment 1

[0050] The invention discloses a water-based fire extinguishing agent and a preparation method thereof. The components and the preparation method are as follows:

[0051] S1. Use 30% NaOH solution to adjust the pH value of the aqueous solution to 8, then add sodium lauroyl hydroxymethylethanesulfonate, and stir for 5 minutes; Add it dropwise to sodium lauroyl hydroxymethylethanesulfonate at a speed of 100%. After all the drops are completed, stir fully for 4 minutes; then add lignin, pentaerythritol triallyl ether and polyacrylamide in sequence, and stir fully for 13 minutes between additions. Dissolve the material evenly, keep stirring during the feeding process, and finally stir for 16 minutes to obtain a uniform initial mixture;

[0052] S2. Keep the water temperature of the water bath at 48°C. Under stirring conditions, gradually add hydrocarbon surfactants, fluorocarbon surfactants, ethylene glycol, foaming agents, flame retardants, For preservatives and anti-corrosion a...

Embodiment 2

[0055] The invention discloses a water-based fire extinguishing agent and a preparation method thereof. The components and the preparation method are as follows:

[0056] S1. Use 30% NaOH solution to adjust the pH value of the aqueous solution to 8, then add sodium lauroyl hydroxymethylethanesulfonate, and stir for 3 minutes; Add it dropwise to sodium lauroyl hydroxymethylethanesulfonate at a high speed, and then fully stir for 3 minutes after all the drops are completed; then add lignin, pentaerythritol triallyl ether and polyacrylamide in sequence, and fully stir for 10 minutes between additions. Dissolve the material evenly, keep stirring during the feeding process, and finally stir for 15 minutes to obtain a uniform initial mixture;

[0057] S2. Keep the water temperature of the water bath at 45°C. Under stirring conditions, gradually add hydrocarbon surfactants, fluorocarbon surfactants, ethylene glycol, foaming agents, flame retardants, For preservatives and anti-corros...

Embodiment 3

[0060] The invention discloses a water-based fire extinguishing agent and a preparation method thereof. The components and the preparation method are as follows:

[0061] S1. Use 30% NaOH solution to adjust the pH value of the aqueous solution to 9, then add sodium lauroyl hydroxymethylethanesulfonate, and stir for 5 minutes; Add it dropwise to sodium lauroyl hydroxymethylethanesulfonate at a high speed, and then fully stir for 5 minutes after all the drops are completed; then add lignin, pentaerythritol triallyl ether and polyacrylamide in sequence, and fully stir for 15 minutes between additions. Dissolve the material evenly, keep stirring during the feeding process, and finally stir for 20 minutes to obtain a uniform initial mixture;

[0062] S2. Keep the water temperature of the water bath at 50°C. Under stirring conditions, gradually add hydrocarbon surfactants, fluorocarbon surfactants, ethylene glycol, foaming agents, flame retardants, For preservatives and anti-corros...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com