Polyurethane foaming equipment capable of adding powder components for multi-channel pouring

A foaming equipment, multi-flow channel technology, applied in the directions of roads, tracks, ballast layers, etc., can solve the problems of low foaming operation efficiency and achieve the effect of improving operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

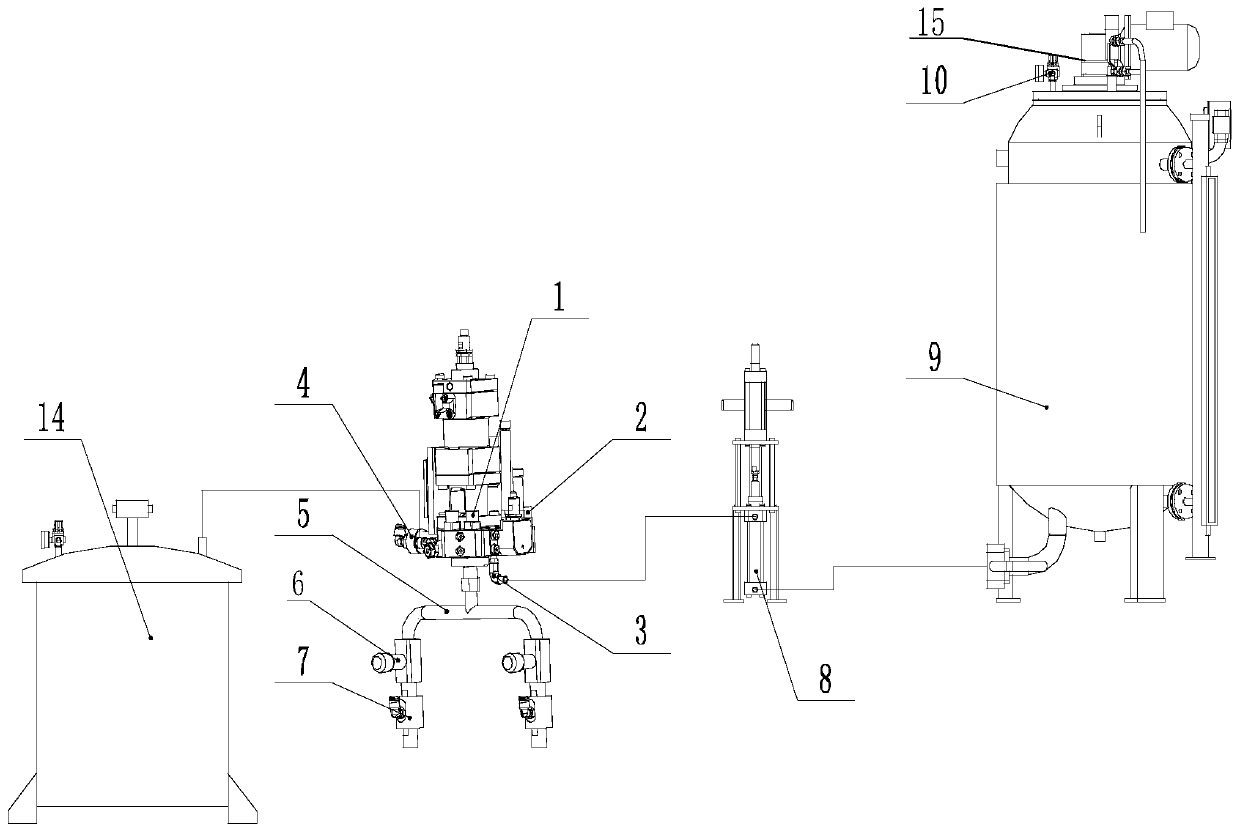

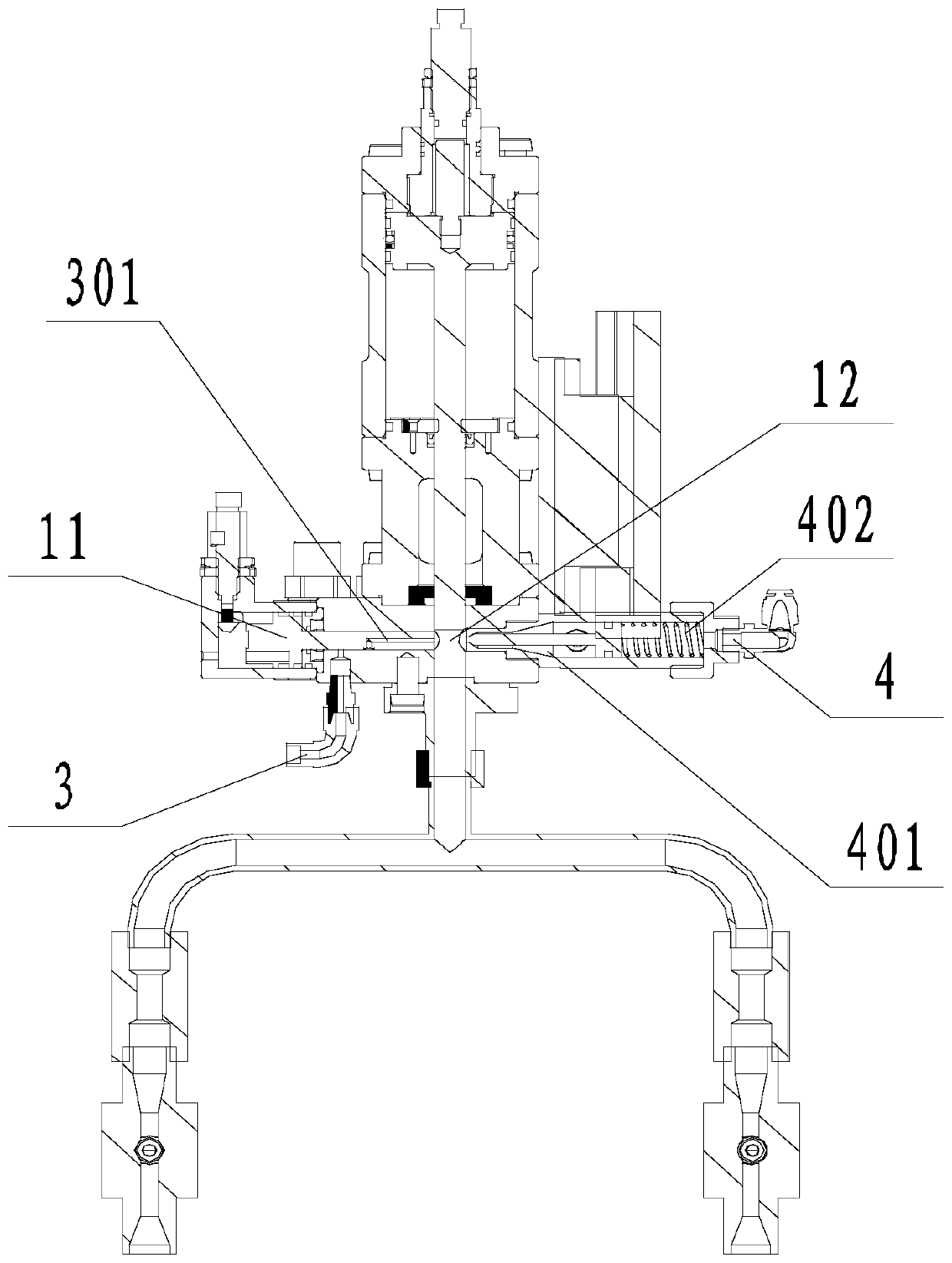

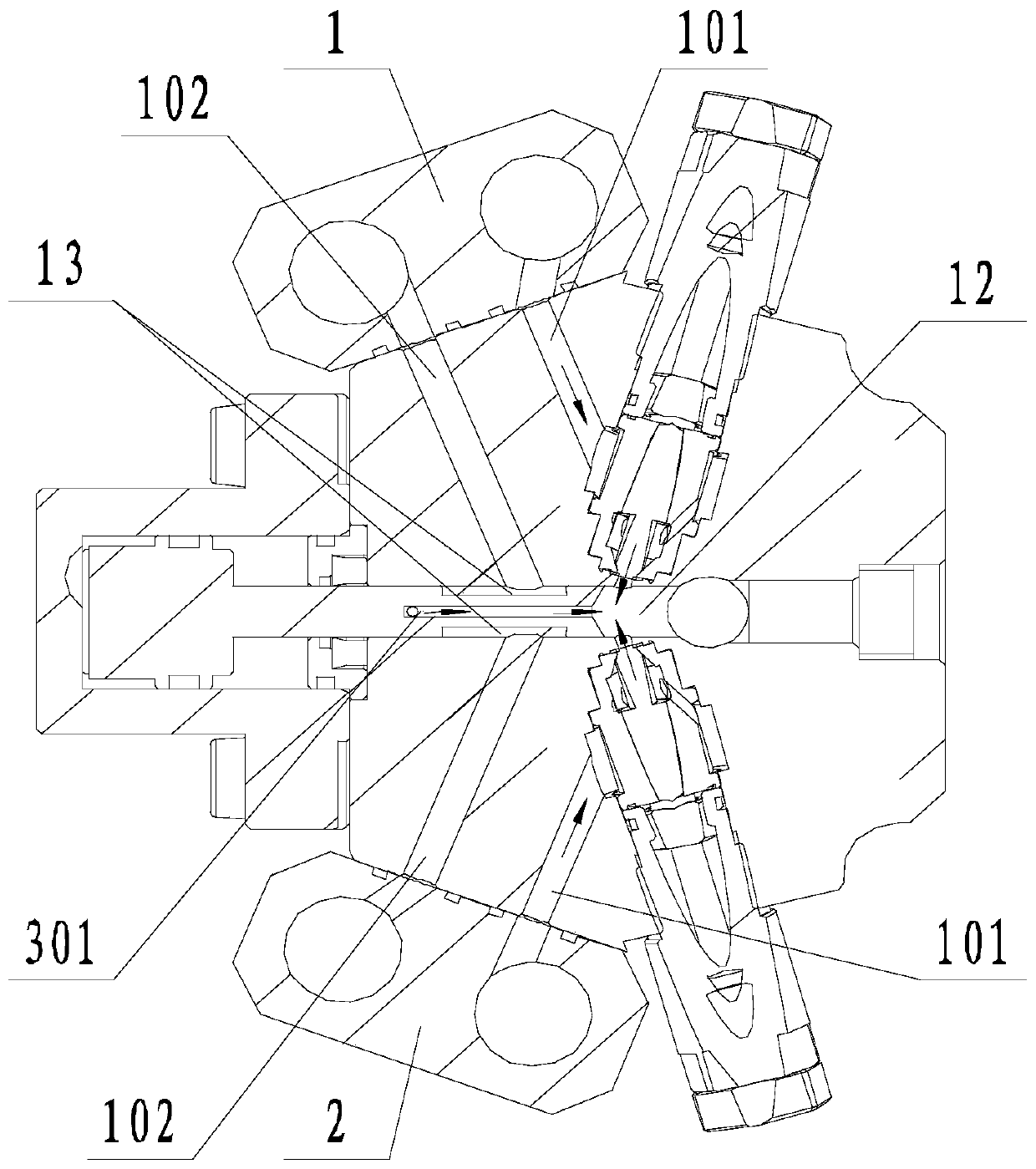

[0039] Such as Figure 1 to Figure 4 The shown polyurethane foaming equipment that can add powder component multi-channel pouring includes gun head body, which is equipped with component A injection device 1 and component B injection device 2, and the inside of the gun head body is set with group A The sub-injection device 1, the small piston 11 and the mixing chamber 12 matched with the component B injection device 2 also include a component C injection device 3, and a component C flow channel matching the component C injection device 3 is set on the small piston 11 301, the C component flow channel 301 is connected to the mixing chamber 12; when the small piston 11 is in the working position, the C component flow channel 301 is in communication with the C component injection device 3; when the small piston 11 is in the stop position, the C component flow The channel 301 is not in communication with the C component injection device 3 . Among them, component C is a premix of ...

Embodiment 2

[0043] Such as Figure 1 to Figure 4 The illustrated polyurethane foaming equipment for multi-channel pouring that can add powder components is based on Example 1. The output end of the gun head body is connected to a flow divider 5, and the flow divider 5 includes two forks. The flow divider 5 includes a base body 501 and a coating layer 502 on the inner wall of the base body 501 , and a split flow regulating valve 6 is set on each branch. The coating 502 is any one of Teflon coating, nano non-stick coating, and metal non-stick coating, or the substrate 501 is directly made of a polytetrafluoroethylene-lined pipe.

[0044] The component A injection device 1 and the component B injection device 2 both include an input flow channel 101 and an output flow channel 102, and also include a circulation mechanism, which is used to make the input flow channel 101 and the output flow channel of the A component injection device 1 102 is connected, and the input flow channel 101 of the ...

Embodiment 3

[0048] Such as Figure 1 to Figure 4 The shown polyurethane foaming equipment that can add powder components to multi-channel pouring, on the basis of any of the above-mentioned embodiments, a positive pressure cleaning device 4 is set on the gun head body, and the positive pressure cleaning device 4 is used to spray the gun head body Positive pressure air is input inside; a negative pressure cleaning device 7 is provided on each branch of the diverter 5, and the negative pressure cleaning device 7 is used to create negative pressure in the corresponding branch. It also includes a release agent injecting device 14 connected to the positive pressure cleaning device 4, and the positive pressure cleaning device 4 is used to inject the release agent into the inner wall of the diverter.

[0049] Preferably, the positive pressure cleaning device 4 is located on the opposite side of the C component flow channel 301, and the positive pressure cleaning device 4 includes a sealing pisto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com