Spraying device for soil treatment

A spraying device and soil technology, which is applied in the restoration of polluted soil, grain treatment, etc., can solve the problems of the influence of restoration effect, insufficient integration of soil and restoration agent, insufficient fragmentation, etc., and achieve the effect of enhancing the restoration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

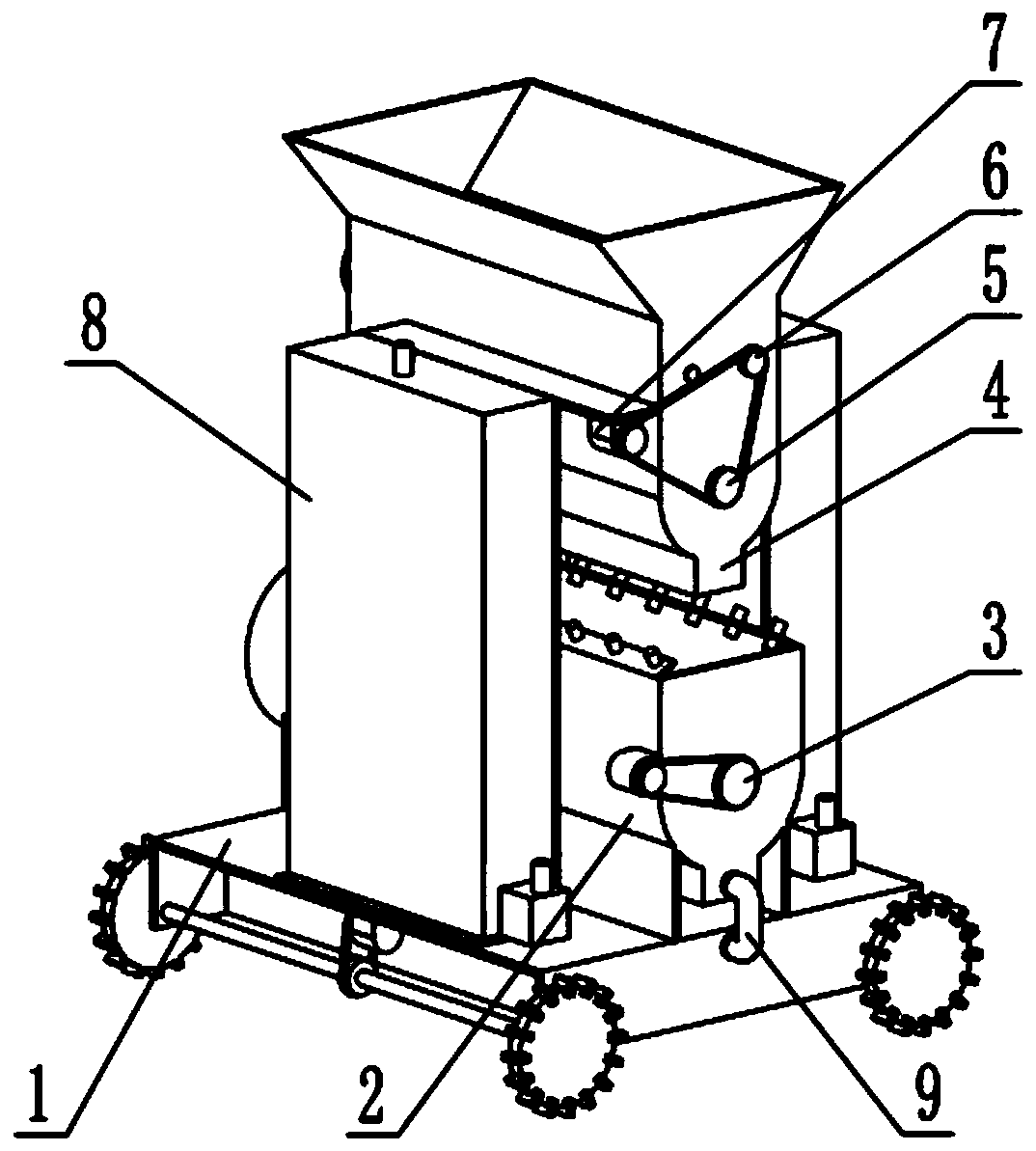

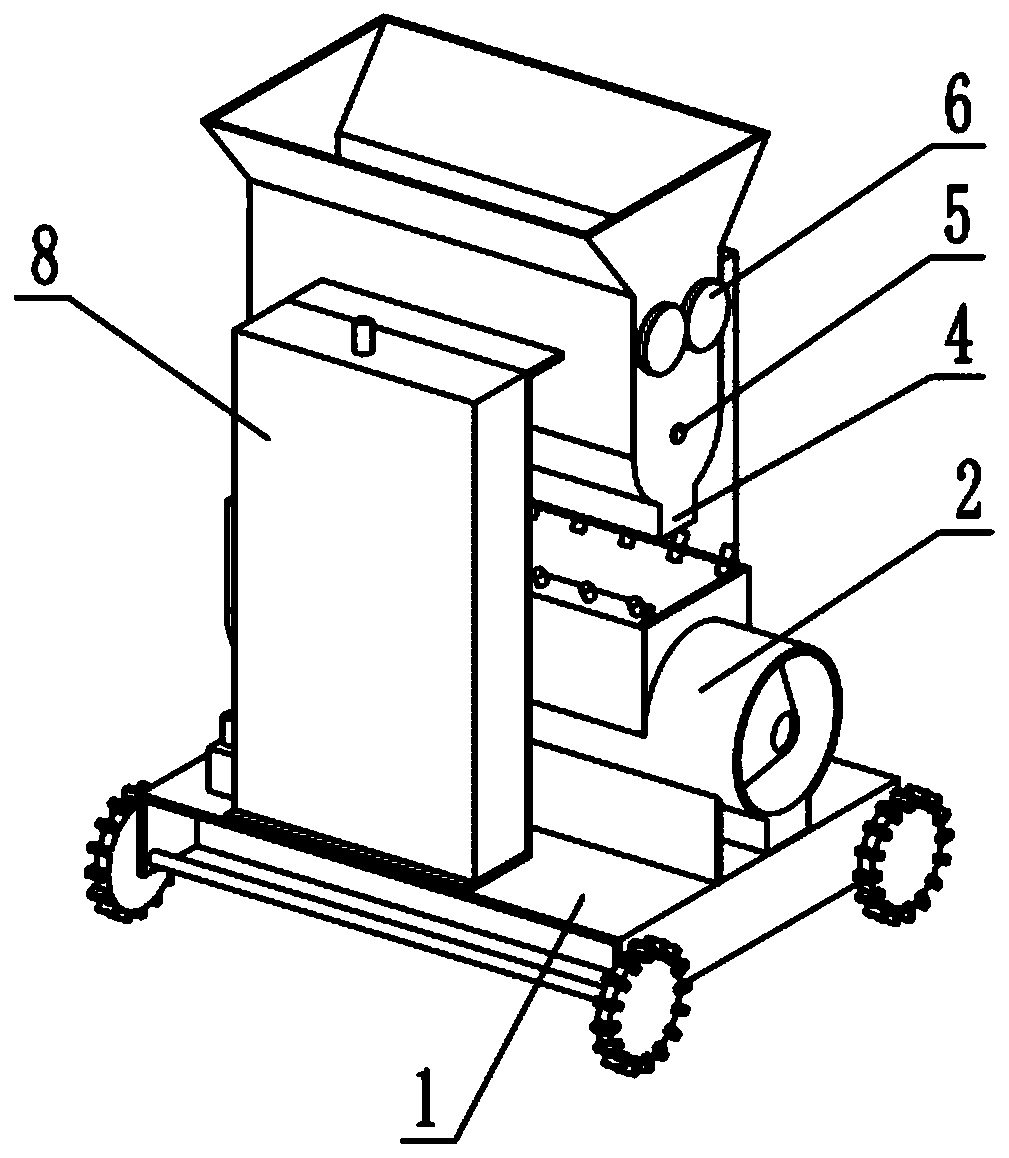

[0030] Such as Figure 1-11 As shown, a soil treatment spraying device includes a moving frame 1, a soil spraying frame 2, an extruding mechanism 3, a crushing frame 4, a crushing mechanism 5, a clamping mechanism 6, a power motor 7, a spraying and containing mechanism 8 and a connecting pipe 9 , the soil spraying frame 2 is fixedly connected to the upper end of the mobile frame 1, the extrusion mechanism 3 is rotatably connected in the soil spraying frame 2, the crushing frame 4 is fixedly connected to the mobile frame 1, and the crushing frame 4 Located directly above the soil spraying frame 2, the crushing mechanism 5 and the clamping mechanism 6 are both rotatably connected in the crushing frame 4, the clamping mechanism 6 is located directly above the crushing mechanism 5, and the power motor 7 Fixedly connected on the crushing frame 4, the power motor 7 is connected in transmission with the crushing mechanism 5 and the clamping block mechanism 6. There are two spraying a...

specific Embodiment approach 2

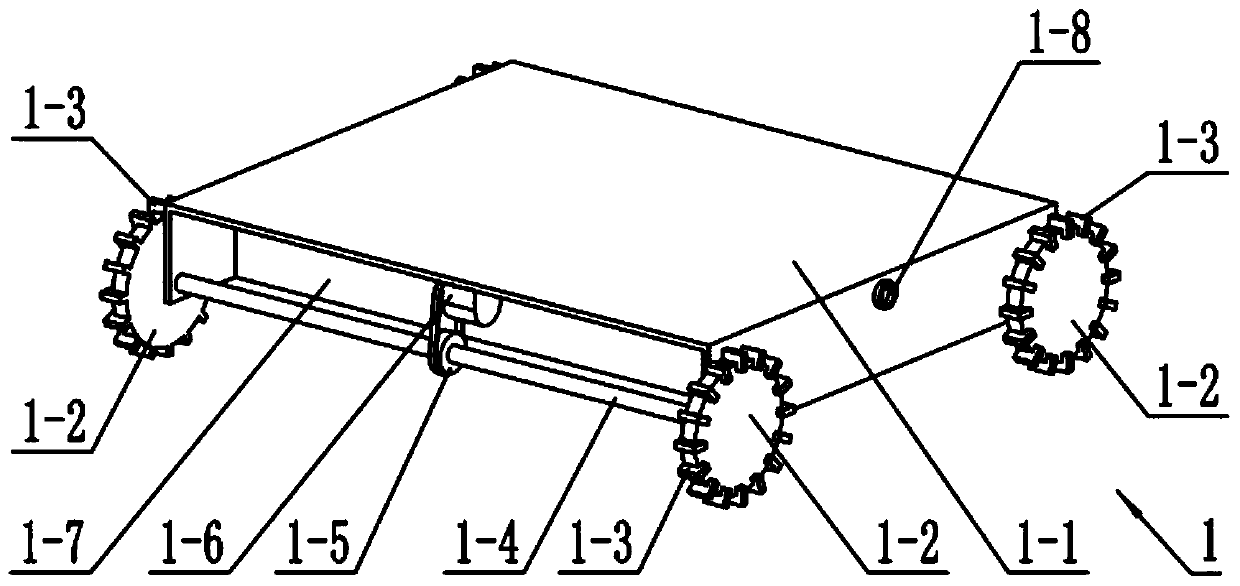

[0033] Such as Figure 1-11 As shown, the mobile frame 1 includes a mobile main board 1-1, a mobile wheel 1-2, a mobile shaft 1-4, a mobile pulley 1-5, a mobile motor 1-6, a mixed liquid tank 1-7 and a liquid inlet Pipe 1-8, the lower end of mobile main board 1-1 is provided with mixed liquid tank 1-7, and the side end of mixed liquid tank 1-7 is provided with liquid inlet pipe 1-8, and the connection between liquid inlet pipe 1-8 and connecting pipe 9 The lower end is connected, the front and rear ends of the mobile main board 1-1 are connected to the mobile shaft 1-4 through bearing rotation, and the two ends of the two mobile shafts 1-4 are fixedly connected to the mobile wheel 1-2, and one of the mobile shafts 1-4 4 is provided with a moving pulley 1-5, and the moving motor 1-6 is fixedly connected to the lower end face of the moving main board 1-1. The lower end face of -1, the mobile motor 1-6 is connected to the power supply through wires and switches;

[0034] Start ...

specific Embodiment approach 3

[0036] Such as Figure 1-11 As shown, the soil spraying rack 2 includes a round pipe 2-1, an opening frame 2-2, a round pipe support plate 2-3, a blocking plate 2-4, a lower connection box 2-5, and a liquid outlet pipe 2-6 , nozzle fixed plate 2-7, nozzle 2-8, liquid outlet hole 2-9 and tapered pipe 2-10, the circular tube support plate 2-3 is provided with two, and the lower end of two circular tube support plates 2-3 is fixed Connected on the mobile main board 1-1, the upper ends of the two circular tube support plates 2-3 are fixedly connected with circular tubes 2-1, the upper ends of the circular tubes 2-1 are provided with opening frames 2-2, and the upper ends of the circular tubes 2-1 The lower end is fixedly connected with a lower connection box 2-5, and the wall of the round pipe 2-1 in the lower connection box 2-5 is provided with a plurality of liquid outlet holes 2-9, and the side end of the lower connection box 2-5 is provided with a liquid outlet Pipe 2-6, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com