Control system of live-working robot and live-working robot

A control system and live work technology, applied in the direction of program control manipulators, manipulators, manufacturing tools, etc., can solve the problems of high-risk operation labor volume, high-pressure working environment of operators, etc., to facilitate connection and maintenance, avoid economic losses, and reduce weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

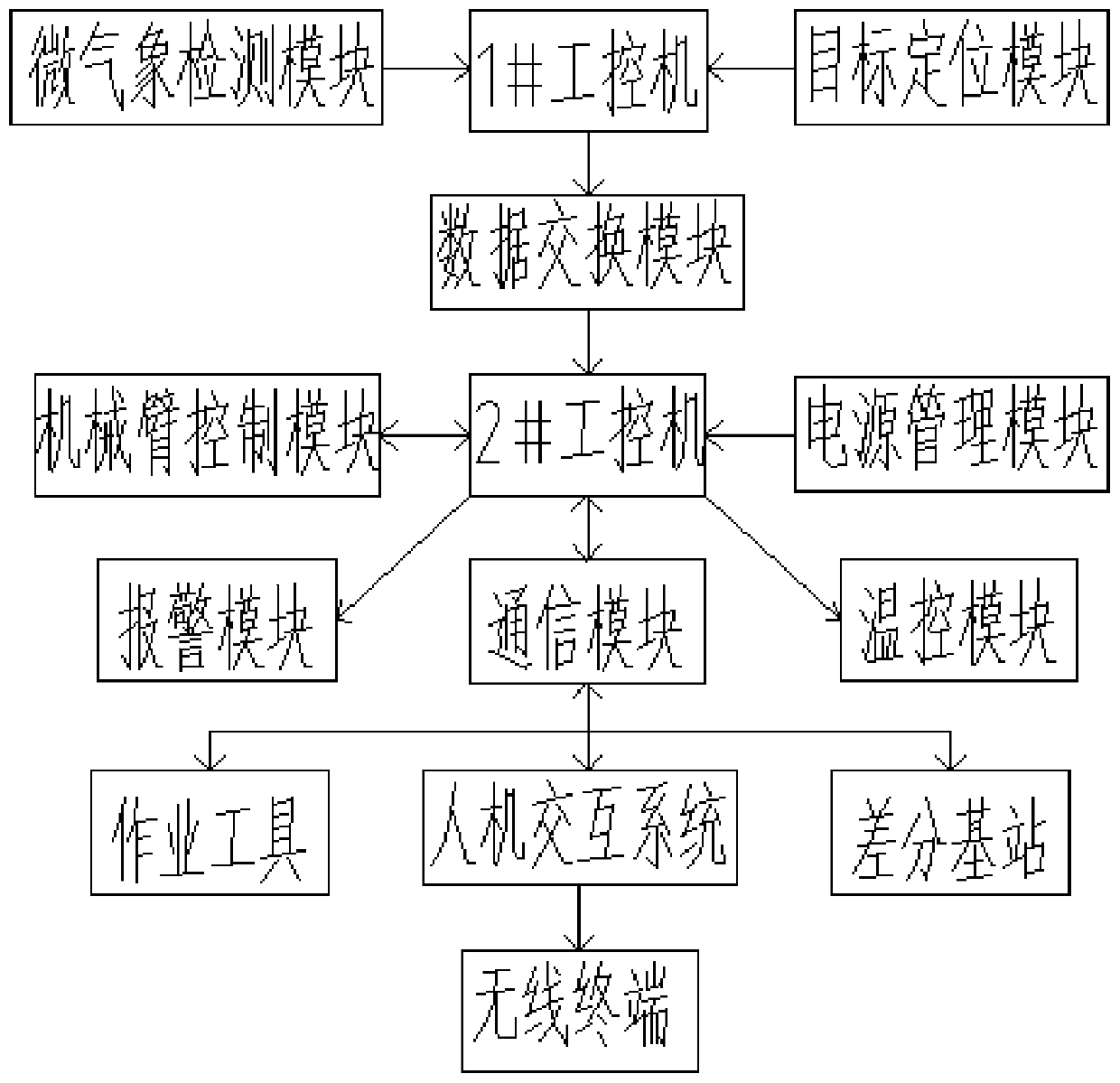

[0038] A live working robot control system, such as figure 1 As shown, it includes a main control system module and a data exchange module. The main control system module includes 1# industrial computer and 2# industrial computer. The model of the industrial computer is AAEON PICO-ITX. communication to realize data interaction; the control system also includes a target positioning module, a micro-weather detection module, a manipulator control module, a power management module and a communication module.

[0039] The 1# industrial computer is connected with the target positioning module and the micro-weather detection module; the target positioning module is used to scan and model the work space, obtain the image information parameters of the work scene, and determine the position of the operation object in the robot coordinate system The target positioning module includes a differential GPS module, a fixed visible light camera, a binocular camera, and a laser scanning sensor,...

Embodiment 2

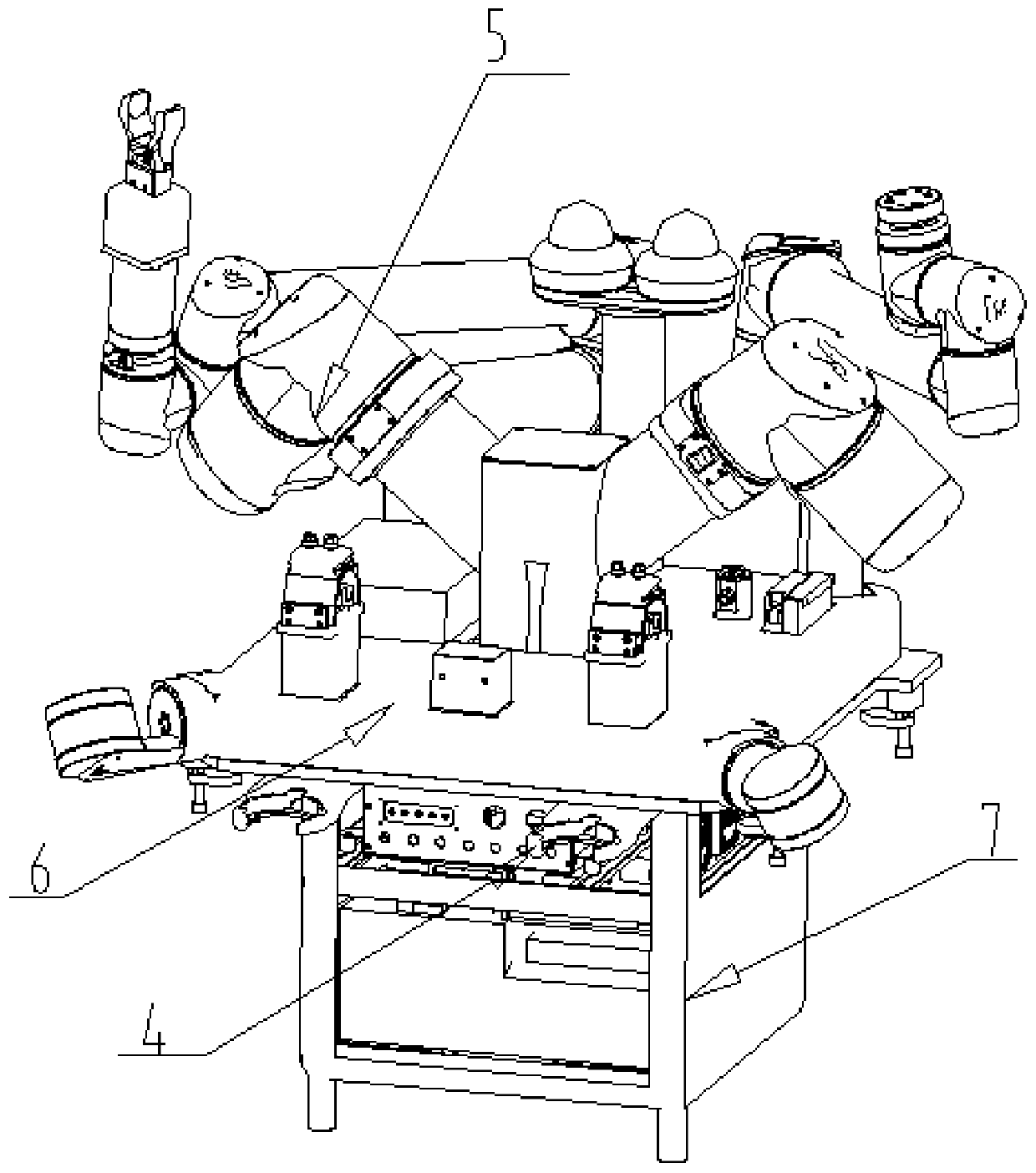

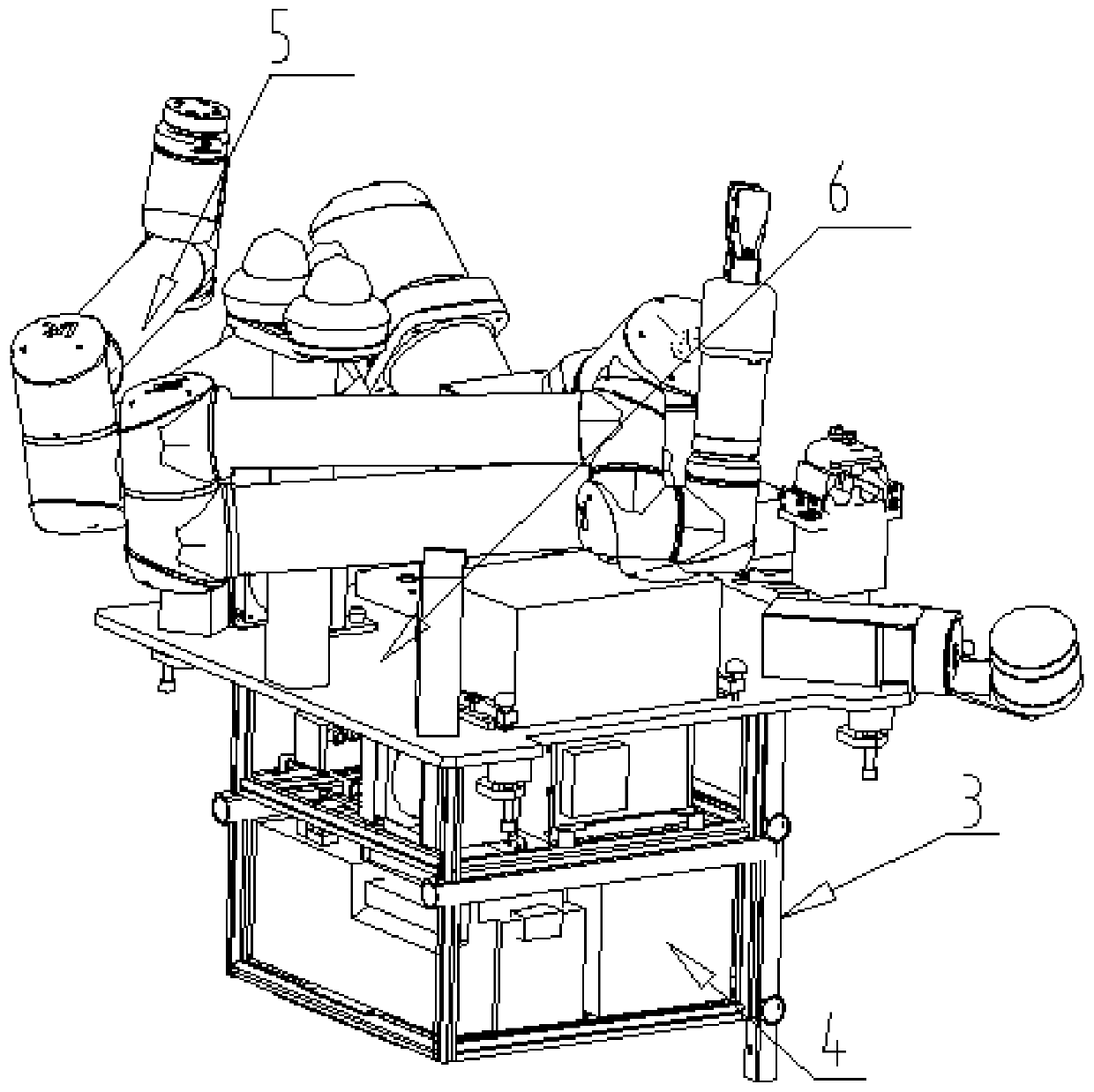

[0049] On the basis of Embodiment 1, a live working robot, such as Figure 2-Figure 3 As shown, it includes the above-mentioned live working robot control system 4, and also includes a frame 3 for installing the control system 4, a mechanical arm module 5, a reference plate table top module 6 and a housing assembly 7; the reference plate table top module 6 includes a heat dissipation module 6-9, lithium battery pack 6-2, tool quick change device 6-5, adapter plate 6-8, reference plate 6-1, clamping mechanism 6-7, laser positioning module 6-4, sleeve recovery module 6-6, wire clamp 6-3, mechanical arm bracket 6-10 and video monitoring module 6-11, wherein, tool quick change device 6-5, reference plate 6-1, laser positioning module 6-4 and wire clamp Tooling 6-3, etc. need to be accurately positioned, and the positioning is carried out through the seam.

[0050] Such as image 3 , Figure 5-Figure 6 As shown, the upper side of the frame 3 is provided with a reference plate 6-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com