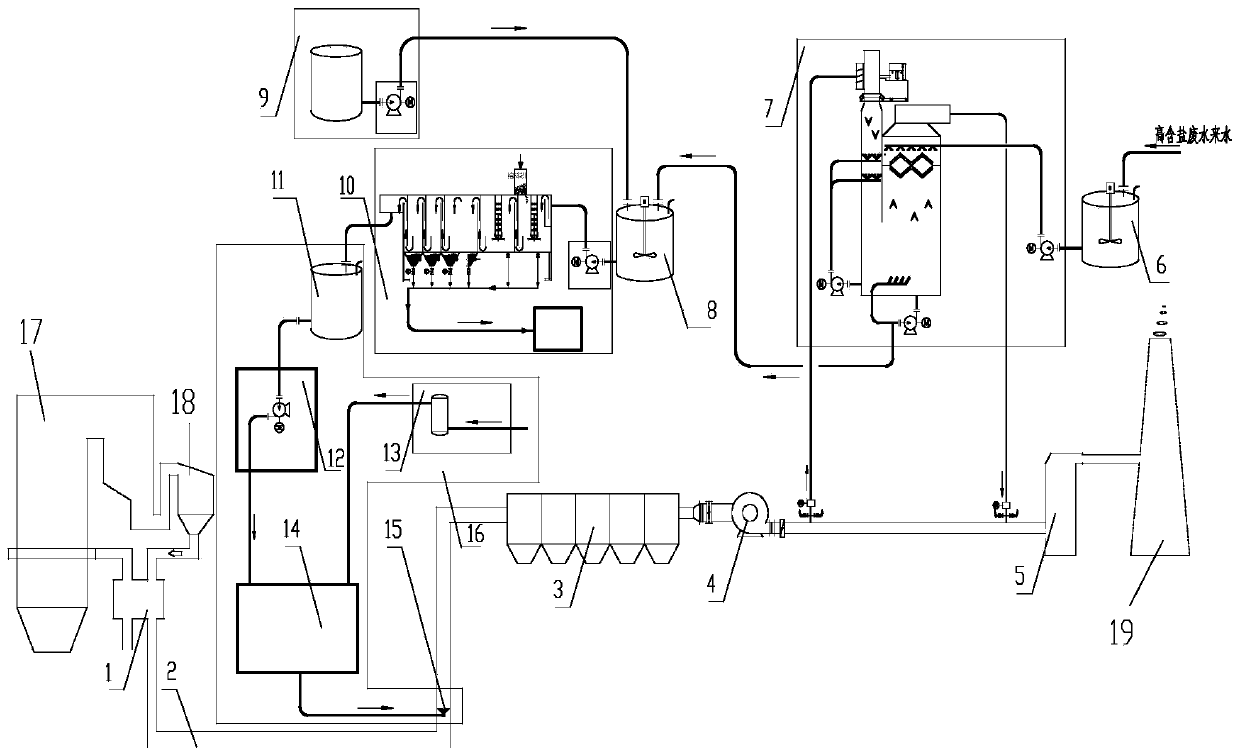

High-salinity wastewater low-temperature bypass thermal method concentration decrement and flue evaporation zero discharge system

A high-salt wastewater, zero-discharge technology, applied in water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc. Availability and Queueable Issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

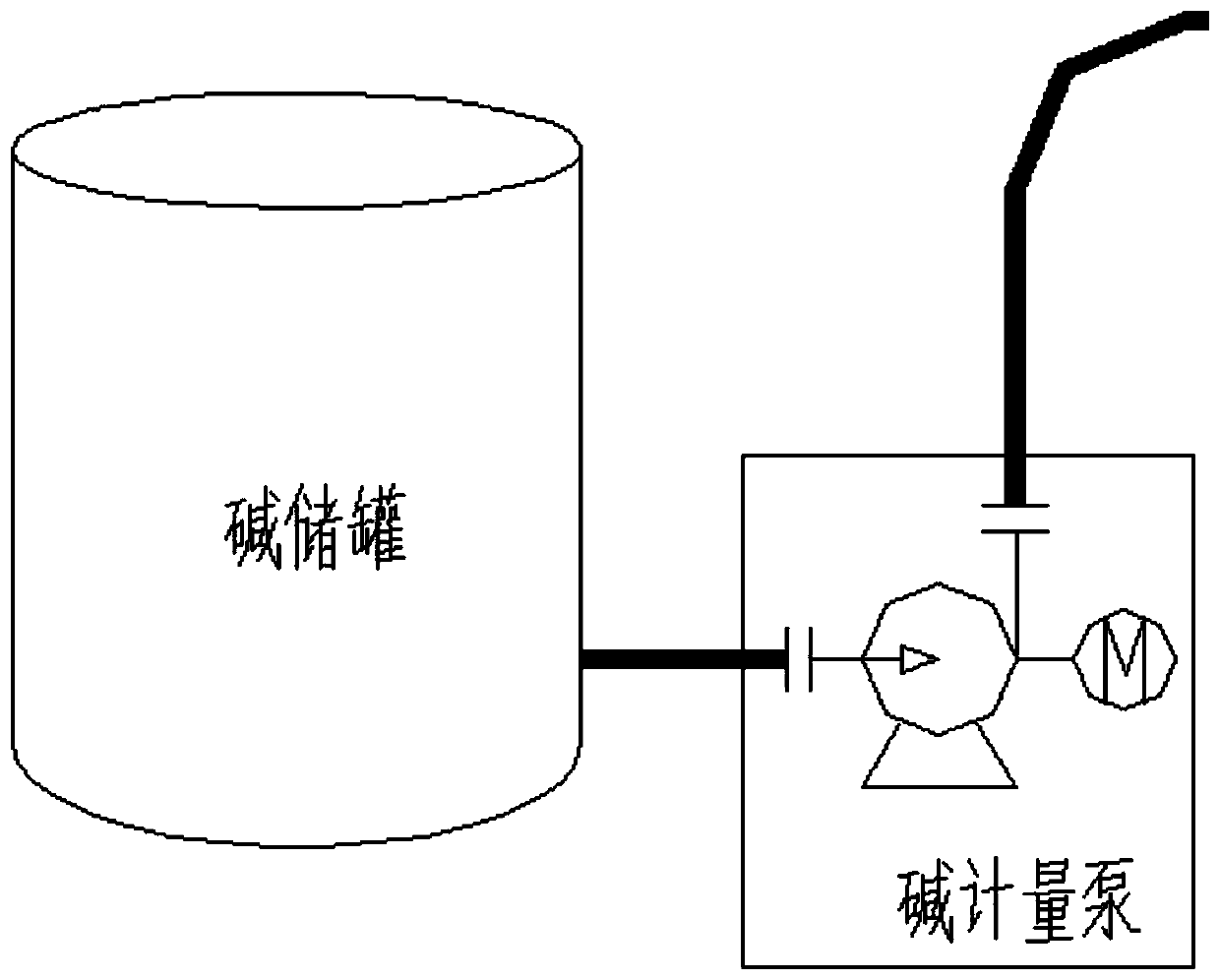

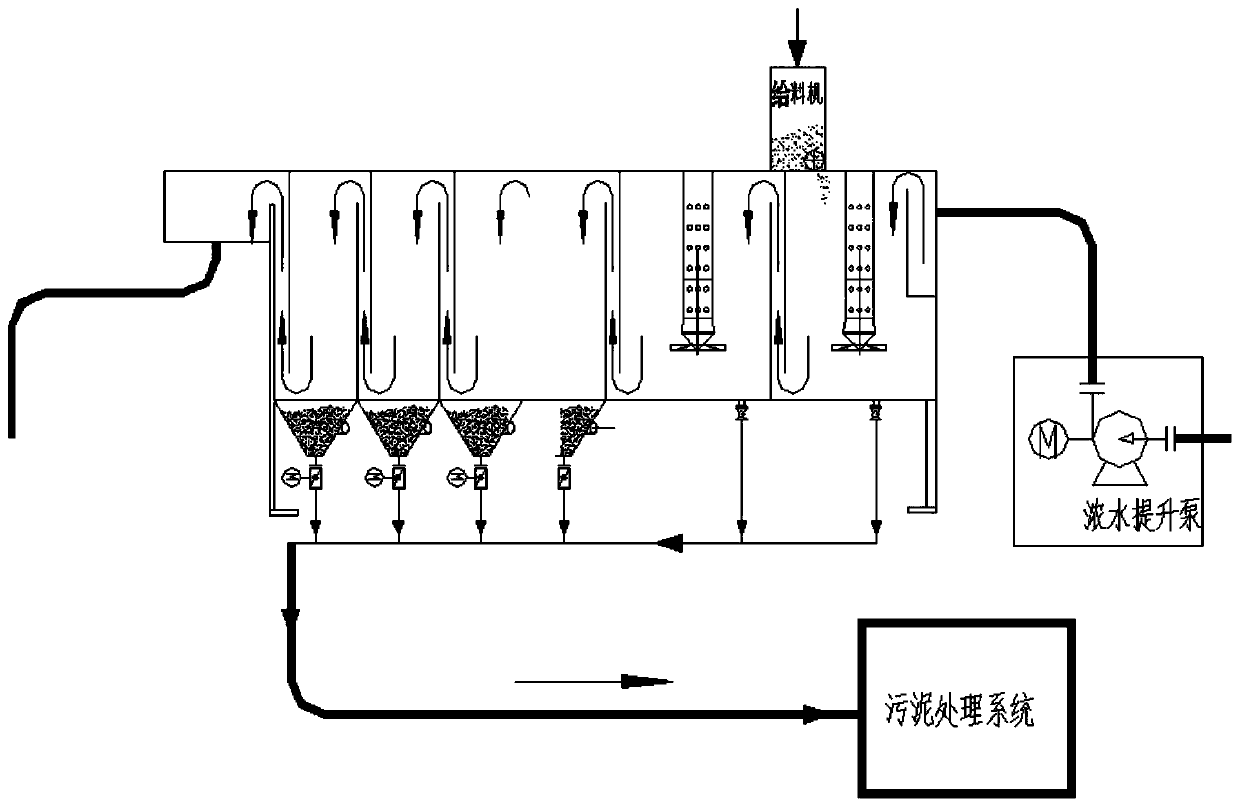

[0023] Embodiment 2, based on above-mentioned embodiment 1, such as Figure 2-5 As shown, the alkali dosing device 9 is made up of an alkali storage tank and an alkali metering pump. The integrated device 10 includes a feeder, a concentrated water lift pump and a sludge treatment system. The low-temperature flue gas concentration unit 7 includes a circulation pump, a disturbance pump and a feed pump. The compressed air device 13 includes a compression control storage tank, and the air source of the compression control storage tank comes from an air compressor station.

Embodiment 3

[0024] Embodiment 3: Based on the above-mentioned embodiment 1, the incoming water of high-salt waste water at the terminal can be one or more of desulfurization waste water, concentrated sewage and acid-base waste water, and can realize the treatment of all incoming water, and then transport it to Low temperature flue gas evaporation system for deep concentration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com