A kind of preparation method and application of 2d nanosheet oil displacement agent

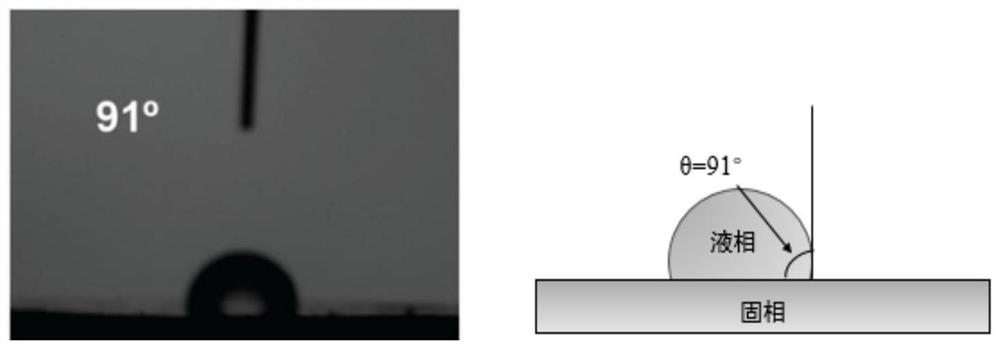

A nano-sheet and oil-displacing agent technology, which is applied in the field of preparation of 2D nano-sheet oil-displacing agent, can solve problems such as low sweep efficiency, residual oil retention, and snapping, and achieve optimized shear resistance, reduced interfacial tension, and The effect of improving the cutting ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with specific embodiments and illustrations.

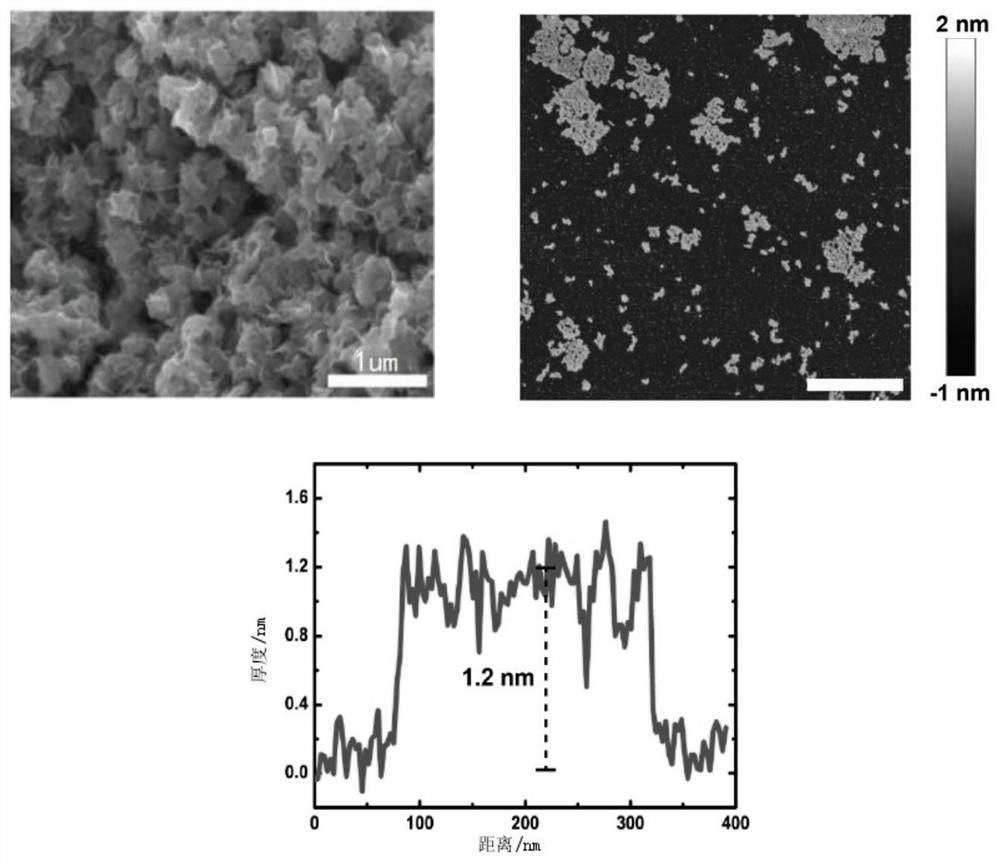

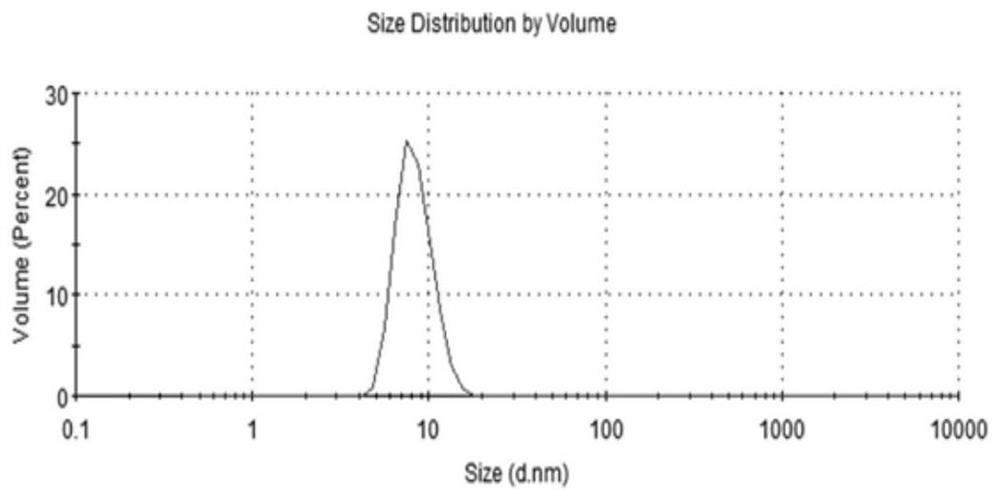

[0035] (1) Modified MoS 2 Suspension preparation: Dissolve hexammonium heptamolybdate and thiourea with a molar ratio of 1:7 in 35mL deionized water, then react at 220°C for 18h at high temperature, after the solution is cooled to room temperature, wash with deionized water and absolute ethanol respectively Wash three times, and finally wash once with water, and dialyze with ultrapure water to remove unreacted reagents and impurities to obtain MoS 2 nanosheets; the prepared MoS 2 Nanosheets and formation water were mixed at a ratio of 0.005wt%, and alkylphenol polyoxyethylene ether was added to the dispersion, in which MoS 2 The mass ratio of nanosheets to alkylphenol polyoxyethylene ether is 1:2, and the modified MoS is obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com