Method for increasing energy utilization rate for escaped carbon monoxide and hydrogen in vacuum decarburization process for molten steel

A technology of vacuum decarburization and carbon monoxide, applied in the field of refining outside the steelmaking furnace, can solve the problems of small amount of oxygen blowing, increase, uncontrollable reaction and escaping gas, etc., to avoid splashing and improve combustion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings, so as to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

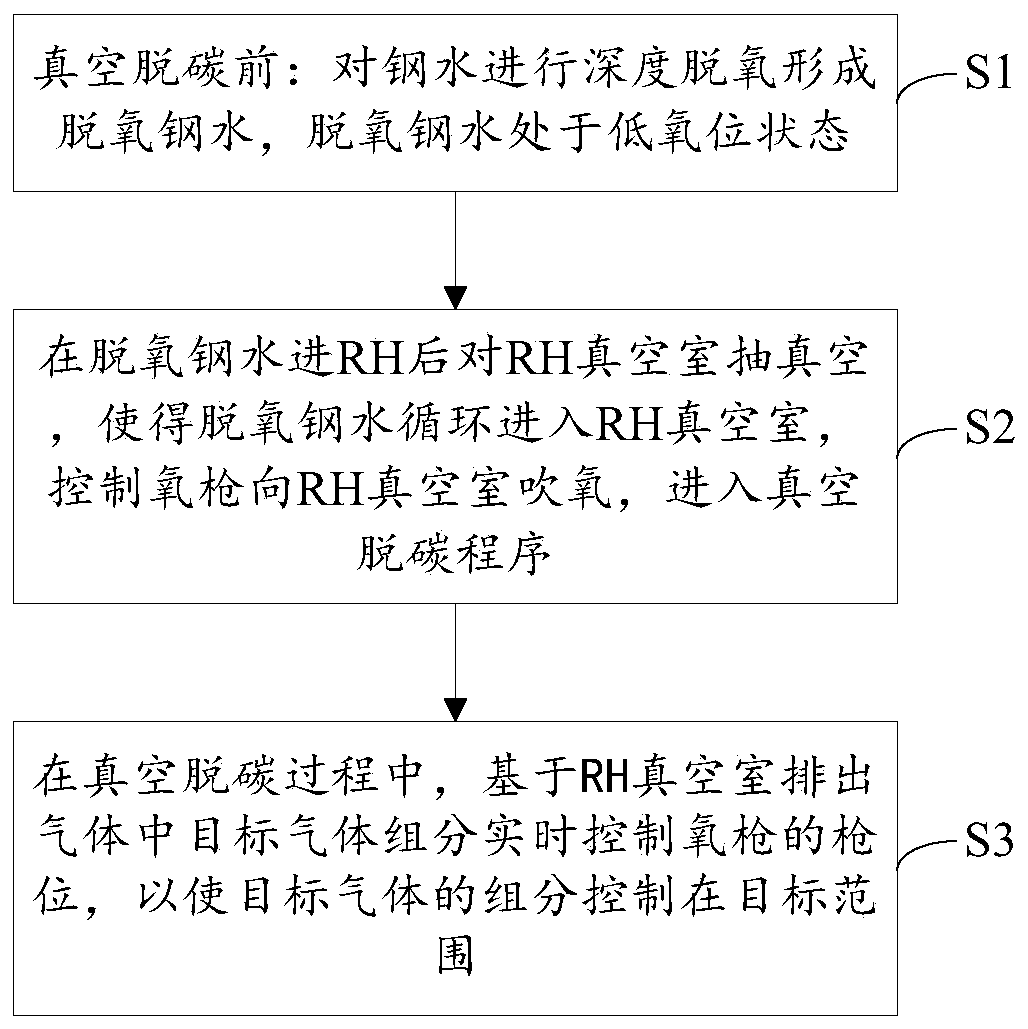

[0022] Control the molten steel in a state of low oxygen level before vacuum decarburization treatment. In order to achieve the target value of decarburization, a large amount of oxygen must be blown to the molten steel. There is a time course for the dissolved oxygen content in the steel to decarburize with a large amount of carbon in the molten steel through oxygen blowing. , during this process, the hydrogen escapes concentratedly, and only a small amount of carbon monoxide is generated when the oxygen flow hits the surface of the molten steel, and the amount of oxygen blown is enough to fully burn the generated carbon monoxide an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com