Flexible steel rail grinding device and steel rail grinding wagon

A rail grinding car, flexible technology, applied in the direction of track, track laying, track maintenance, etc., can solve the problems of limited work efficiency, heavy dust collection device test, high heat, etc., so as not to reduce operating efficiency and precision, and comprehensive operating cost The effect of reducing the debris collection rate is high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

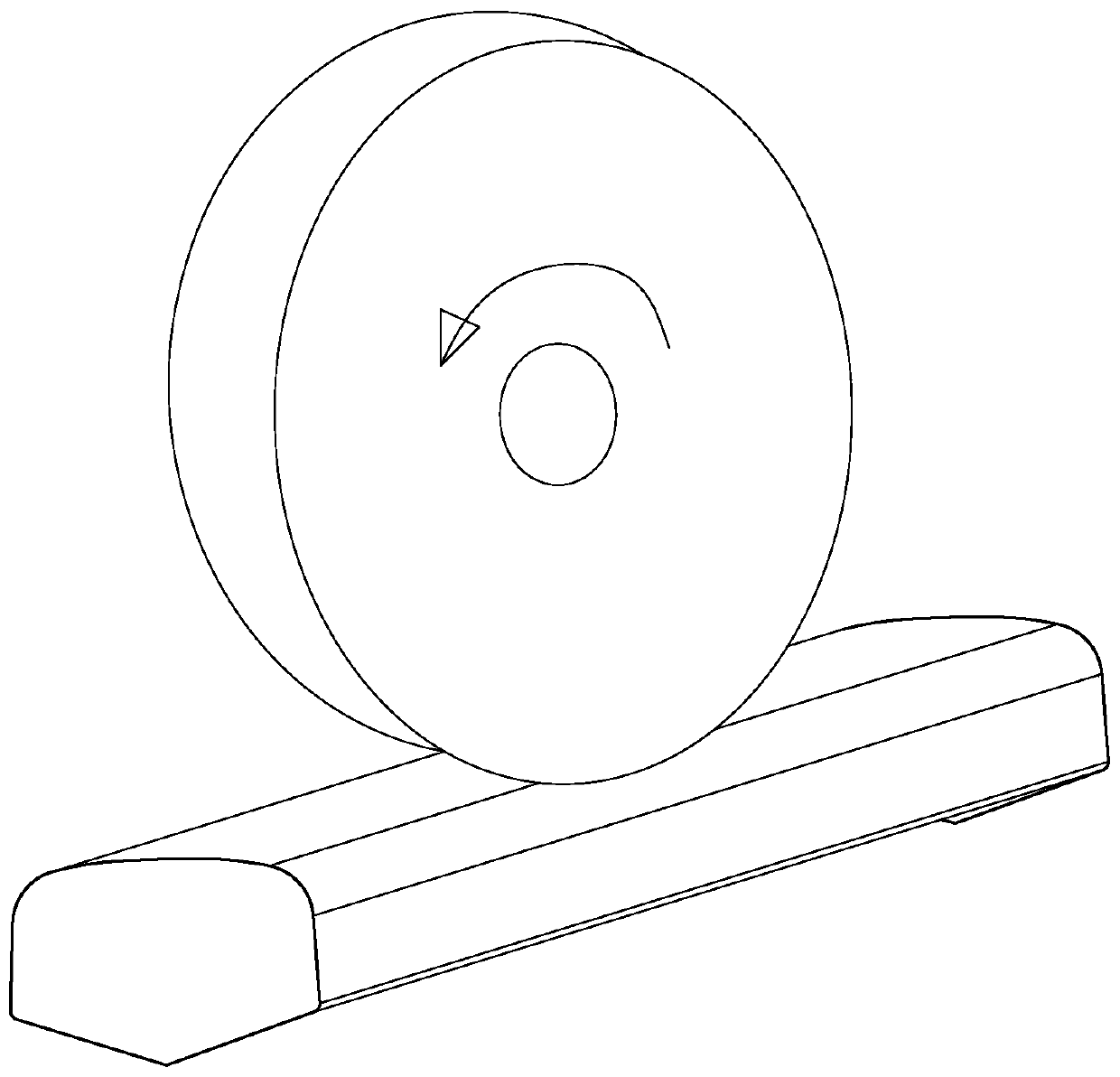

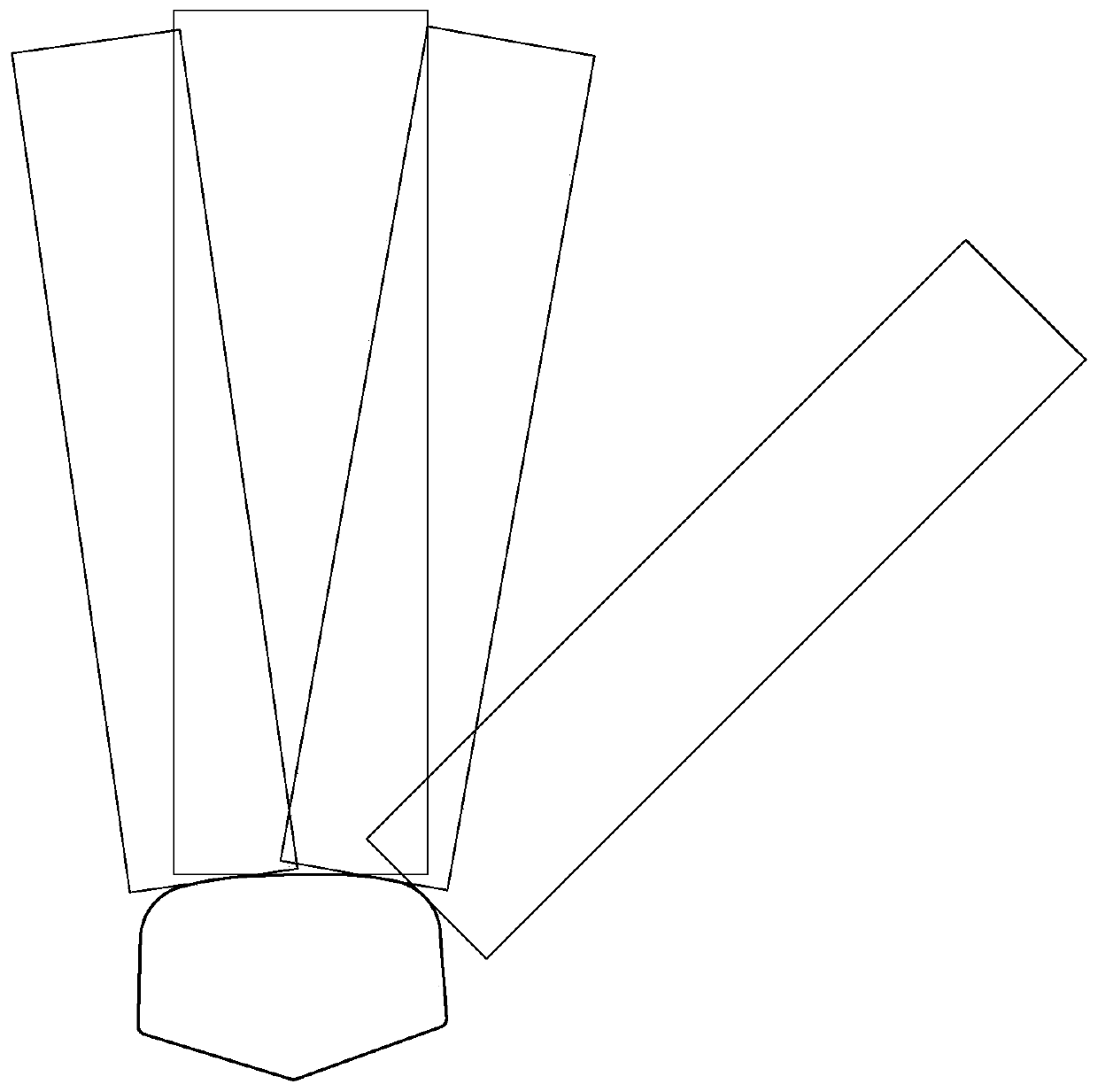

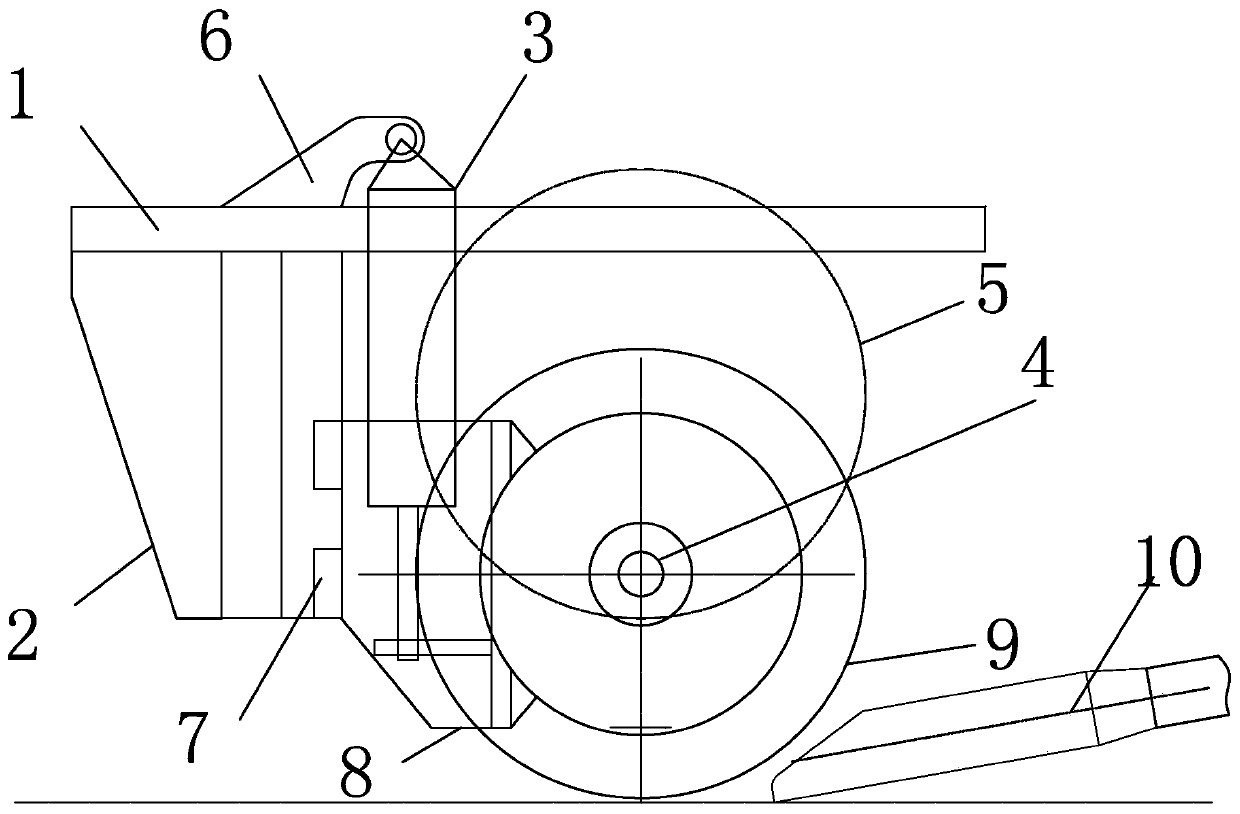

[0043] see Figure 1 to Figure 3 , a flexible rail grinding device, including a mounting frame 1, a vertical plate 2, a feed mechanism 3, a grinding unit 4, a guide rail slider mechanism 7, the top of the vertical plate 2 is fixedly connected to the mounting frame 1, and both are For installing the whole grinding device on the car body, a support rod 6 is also fixedly connected to the mounting frame 1, and the support rod 6 is connected with the feed mechanism 3; the feed mechanism 3 includes a cylinder, and the cylinder body of the cylinder and the support rod 6 hinged, the piston rod end of the cylinder links to each other with the guide rail slider mechanism 7; the guide rail slider mechanism 7 includes a guide rail installed on the vertical plate 2, a slide block matched with the guide rail, and a sliding plate 8 affixed to the slide block, The piston rod of the cylinder is fixedly connected with the sliding plate 8, and the sliding plate 8 is slidably connected with the v...

Embodiment 2

[0048] Example 2: See Figure 4 , a flexible rail grinding car formed by installing several grinding devices, the flexible grinding car includes a car body 11, the car body 11 includes a driver's cab 12 located at the front end of the car body 11, a mechanical and electrical room 13 located in the middle of the car body, And the dust collection device 14 located at the rear end of the car body; power and transmission devices are arranged in the mechanical and electrical room 13 to provide power for the whole vehicle; both sides of the bottom of the car body 11 are also provided with a walking drive system 15 that provides power for the car body, Driven by the driving system 15, the whole vehicle realizes constant pressure or constant load power feeding; multiple grinding devices are installed between the two driving systems 15 on the same side of the vehicle body 11 to realize one-way processing or two-way processing, and the grinding device Installed on the car body 11 by the...

Embodiment 3

[0051] The grinding device can be installed on the milling and grinding car as the "grinding unit" of the milling and grinding car for polishing after milling to eliminate residual ripples.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com