Flexible roadbed asphalt concrete structure and construction method thereof

A technology of asphalt concrete and construction method, which is applied in the direction of roads, roads, on-site cohesive pavements, etc., which can solve the problems of long maintenance period, difficult road surface structure maintenance, service life and service status, which are difficult to accurately predict and judge To achieve the effect of stabilizing the subbase structure, avoiding repeated construction, and reducing the construction period and construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

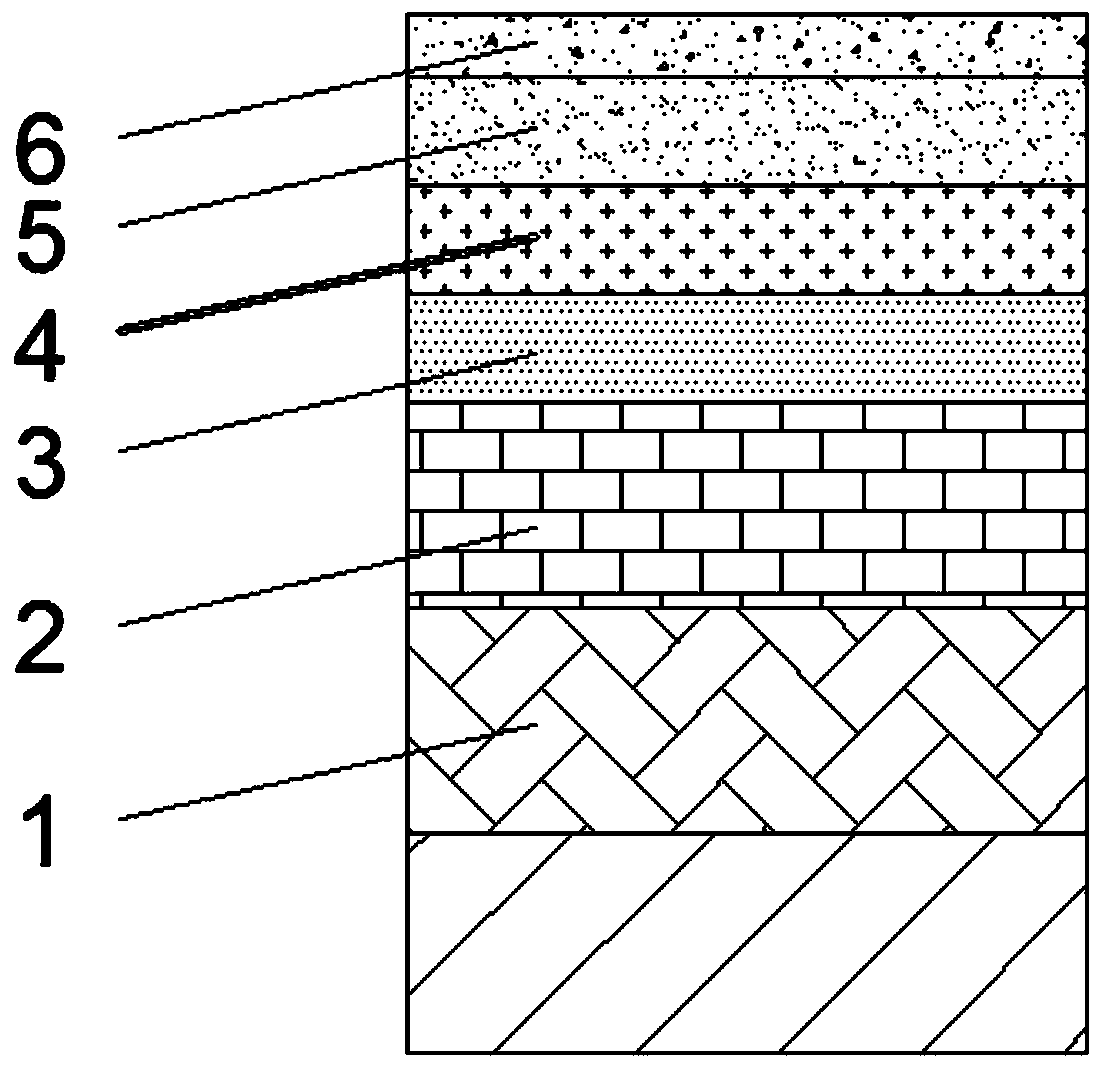

[0062] It can be seen from the accompanying drawings that a flexible roadbed asphalt concrete structure, in which:

[0063] The subbase is broken and compacted by crushing the original cement concrete pavement, and the thickness of the subbase after crushing is 25cm;

[0064] Sprinkle 50% slow-cracking emulsified asphalt on the top surface of the subbase, the dosage is 3kg / square meter;

[0065] Lay graded gravel on the subbase to form the base, the base is paved with graded gravel, and the laying thickness is 15cm;

[0066] Sprinkle 50% slow-cracking emulsified asphalt on the top surface of the base, the dosage is 2.5kg / square meter;

[0067] Lay the anti-fatigue asphalt layer on the base layer. The anti-fatigue asphalt layer is laid with AC-13 asphalt concrete. The AC-13 asphalt concrete is divided into two layings. The laying thickness is 2 layers*4cm, and the total thickness of the fatigue-resistant asphalt layer is 8cm. ;

[0068] Sprinkle modified emulsified asphalt o...

Embodiment 2

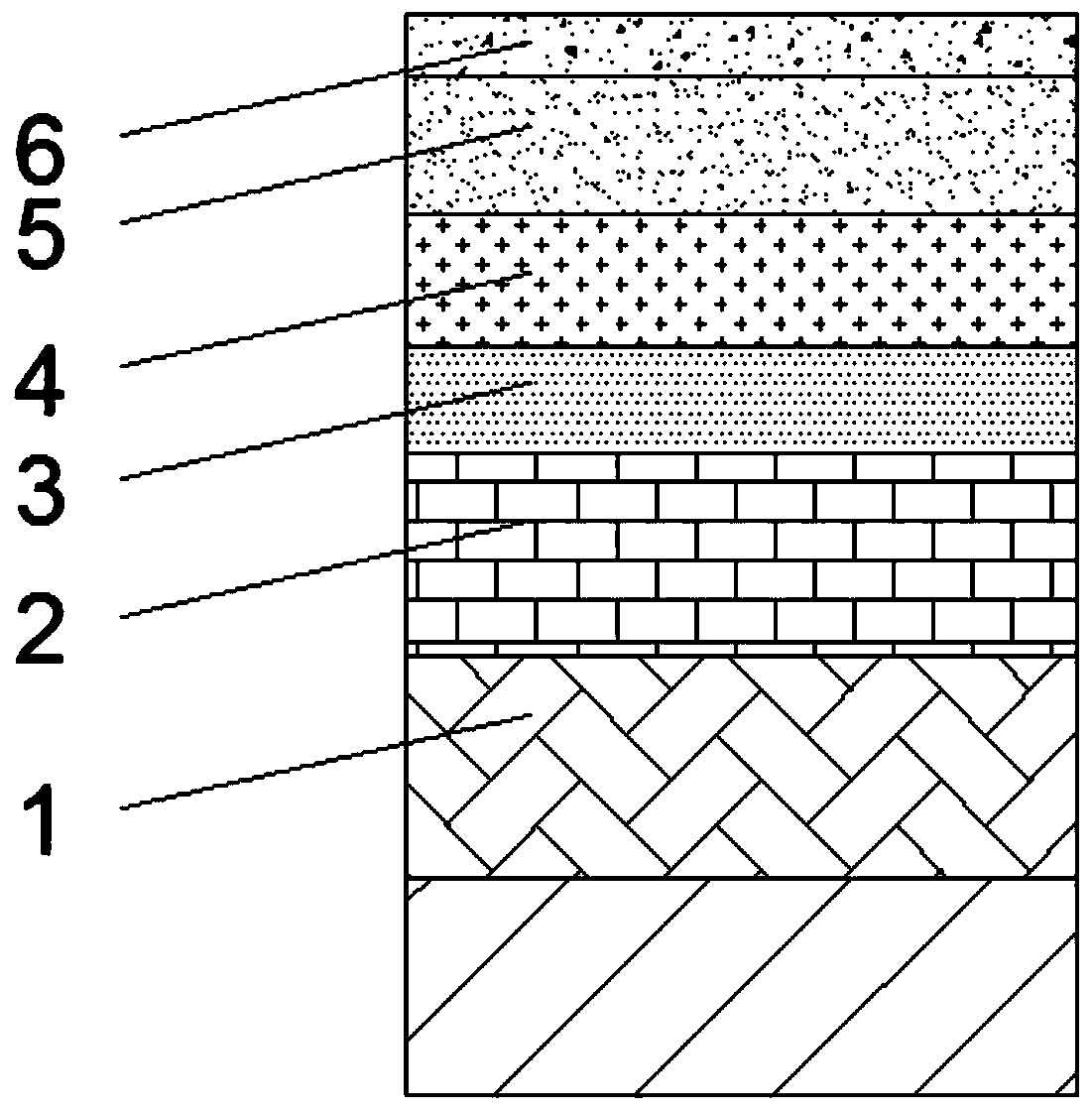

[0075] It can be seen from the accompanying drawings that a flexible roadbed asphalt concrete structure, in which:

[0076] The subbase is broken and compacted by crushing the original cement concrete pavement, and the thickness of the subbase after crushing is 25cm;

[0077] Sprinkle 50% slow-cracking emulsified asphalt on the top surface of the subbase, the dosage is 3kg / square meter;

[0078] Lay graded gravel on the subbase to form the base, the base is paved with graded gravel, and the laying thickness is 15cm;

[0079] Sprinkle 50% slow-cracking emulsified asphalt on the top surface of the base, the dosage is 2.5kg / square meter;

[0080] Lay the anti-fatigue asphalt layer on the base layer. The anti-fatigue asphalt layer is laid with AC-13 asphalt concrete. The AC-13 asphalt concrete is divided into two layings. The laying thickness is 2 layers*4cm, and the total thickness of the fatigue-resistant asphalt layer is 8cm. ;

[0081] Sprinkle modified emulsified asphalt o...

Embodiment 3

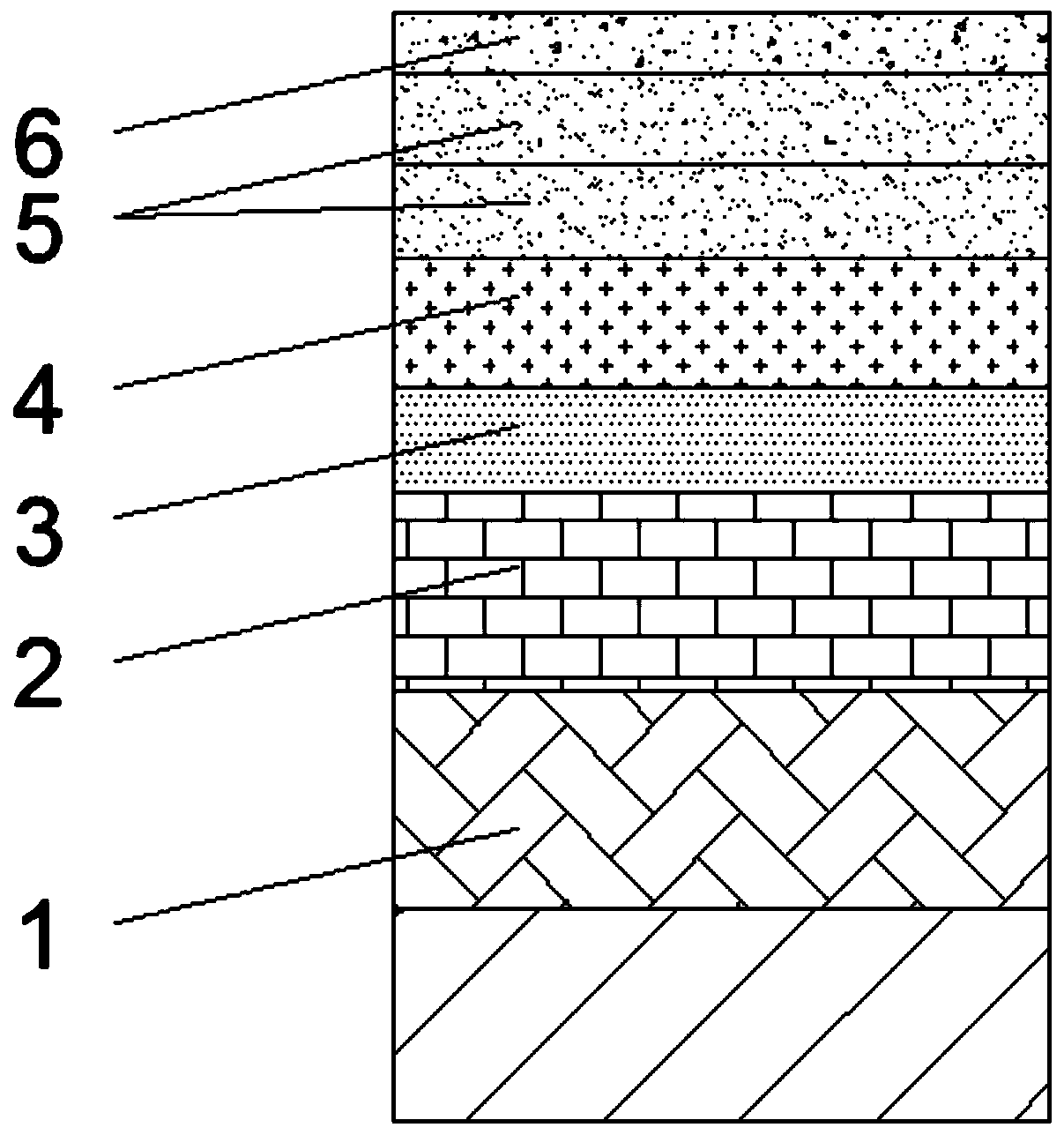

[0087] It can be seen from the accompanying drawings that a flexible roadbed asphalt concrete structure, in which:

[0088] The subbase is broken and compacted by crushing the original cement concrete pavement, and the thickness of the subbase after crushing is 25cm;

[0089] Sprinkle 50% slow-cracking emulsified asphalt on the top surface of the subbase, the dosage is 3kg / square meter;

[0090] Lay graded gravel on the subbase to form the base, the base is paved with graded gravel, and the laying thickness is 16cm;

[0091] Sprinkle 50% slow-cracking emulsified asphalt on the top surface of the base, the dosage is 2.5kg / square meter;

[0092] Lay the anti-fatigue asphalt layer on the base layer. The anti-fatigue asphalt layer is laid with AC-13 asphalt concrete. The AC-13 asphalt concrete is divided into two layings. The laying thickness is 2 layers*4cm, and the total thickness of the fatigue-resistant asphalt layer is 8cm. ;

[0093] Sprinkle modified emulsified asphalt o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com