A Construction Technology of Main Bridge of Double-tower and Single-cable Plane Low-tower Cable-Stayed Bridge

A low-tower cable-stayed bridge and construction technology technology, applied in cable-stayed bridges, bridges, bridge construction and other directions, can solve the problems of complex engineering technology, large deck width of Pumen bridge, and many technical difficulties, and achieve structural safety. High, reasonable construction steps, the effect of optimizing the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

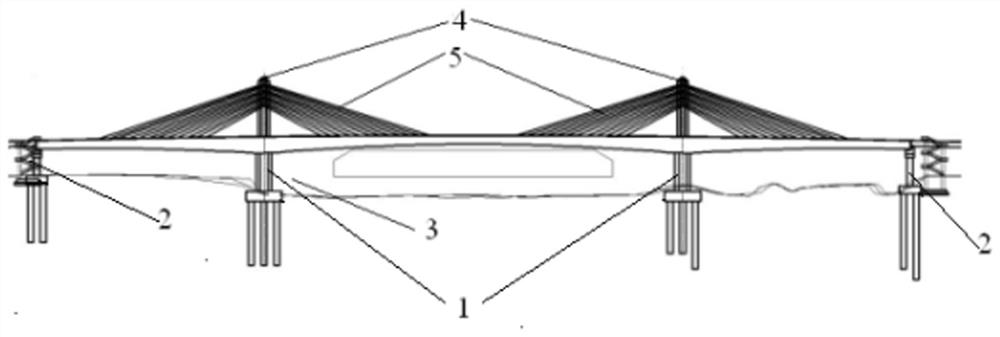

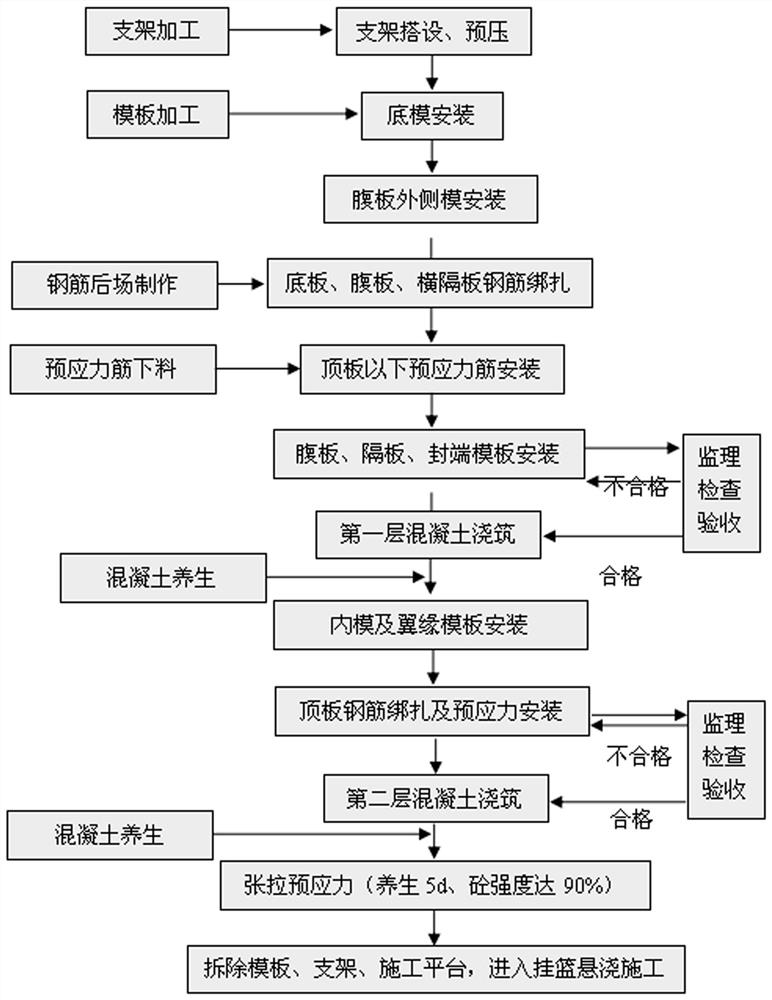

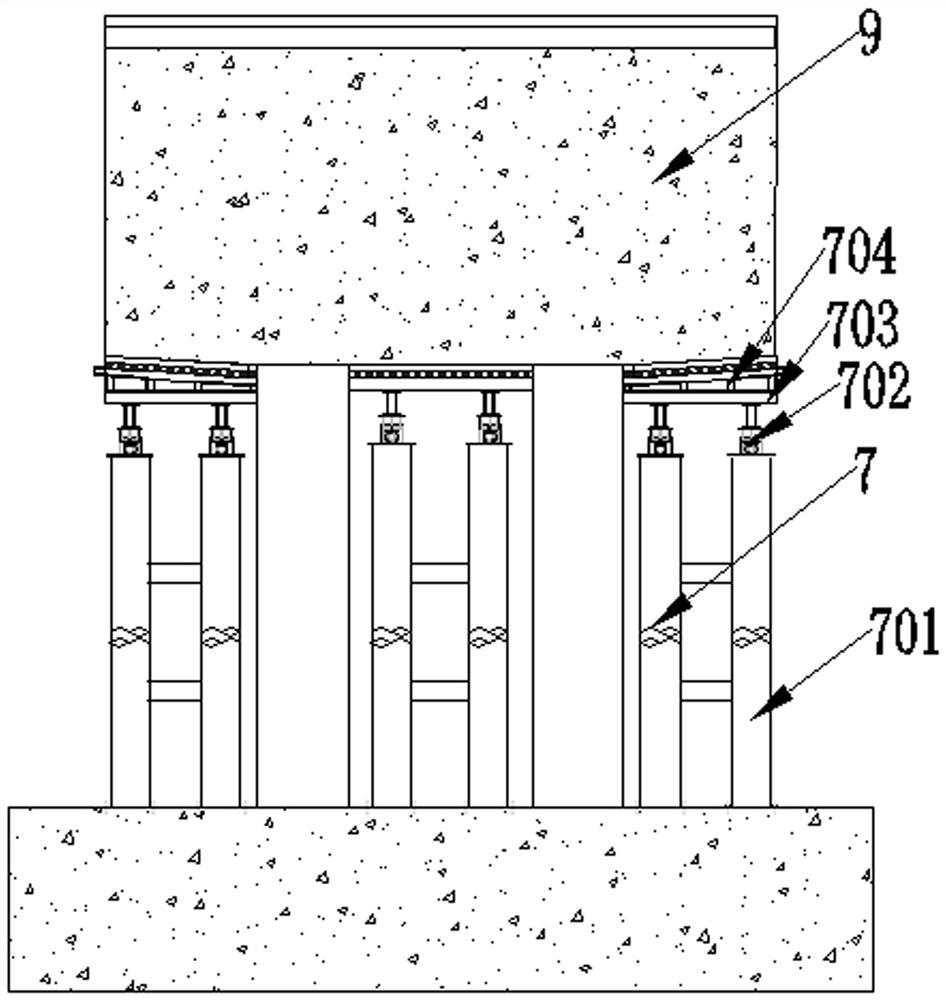

[0041] During the specific implementation, the bridge span of Pumen Bridge is 4×30+90+165+90+4×30, the main bridge is 90+165+90 meters prestressed concrete low-tower cable-stayed bridge, and the approach bridges on both sides are 30 meters span First simply supported and then continuously prestressed concrete T-beam, the bridge is 593 meters long. For the elevation of the main bridge, see figure 1 As shown, it includes two main piers 1 and two transition piers 2. The main girder 3 is a single-box three-chamber straight-web box girder. The vertical prestressed system is designed according to the fully prestressed concrete components. The main tower of the bridge is 23 meters high above the bridge deck and is consolidated with the box girder. There are 2 main towers in the whole bridge. The concrete of the cable tower 4 is C55 composite fiber concrete. The cross-section of the main tower is a quadrilateral with grooves, and the transverse dimension is 2.5m. The dimension along...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com