Device and method for testing drag reduction performance of super-hydrophobic surface

A super-hydrophobic surface and testing device technology, which is applied in the direction of measuring devices, surface/boundary effects, instruments, etc., can solve the problems of the influence of the accuracy of the measurement results, the limitation of the test process, and poor temperature characteristics, so as to achieve easy and accurate testing in the test process , good temperature characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

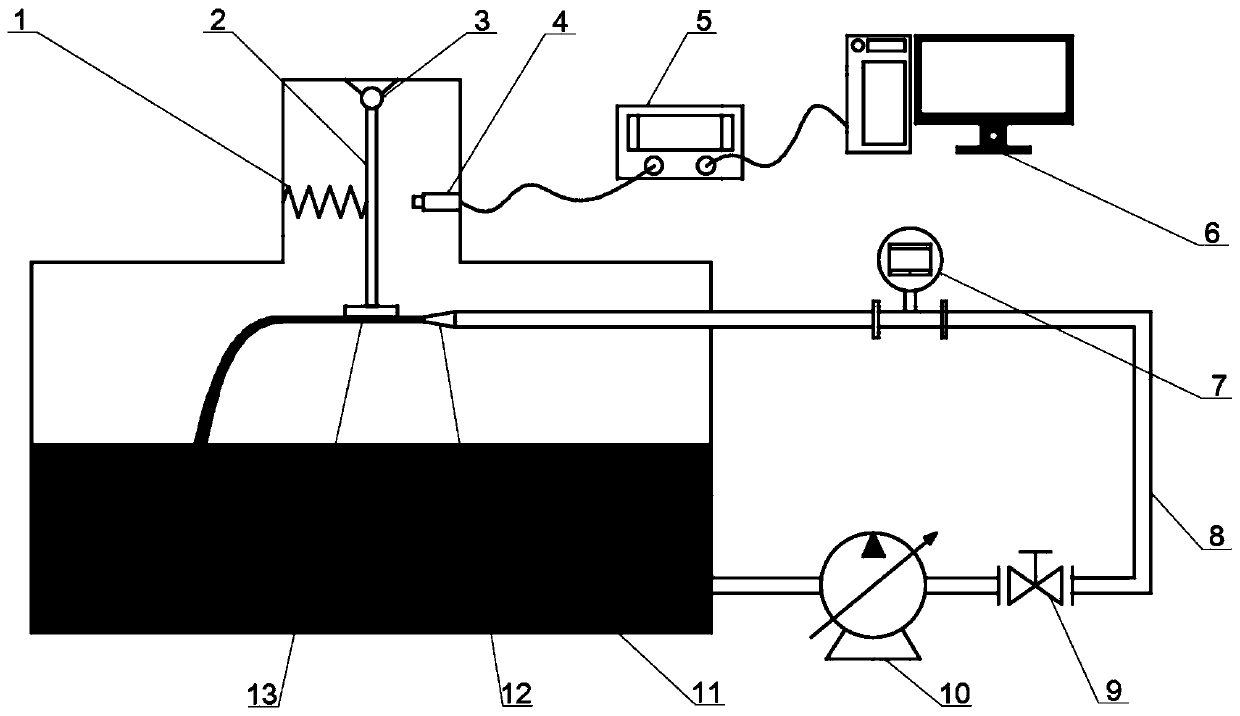

[0026] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

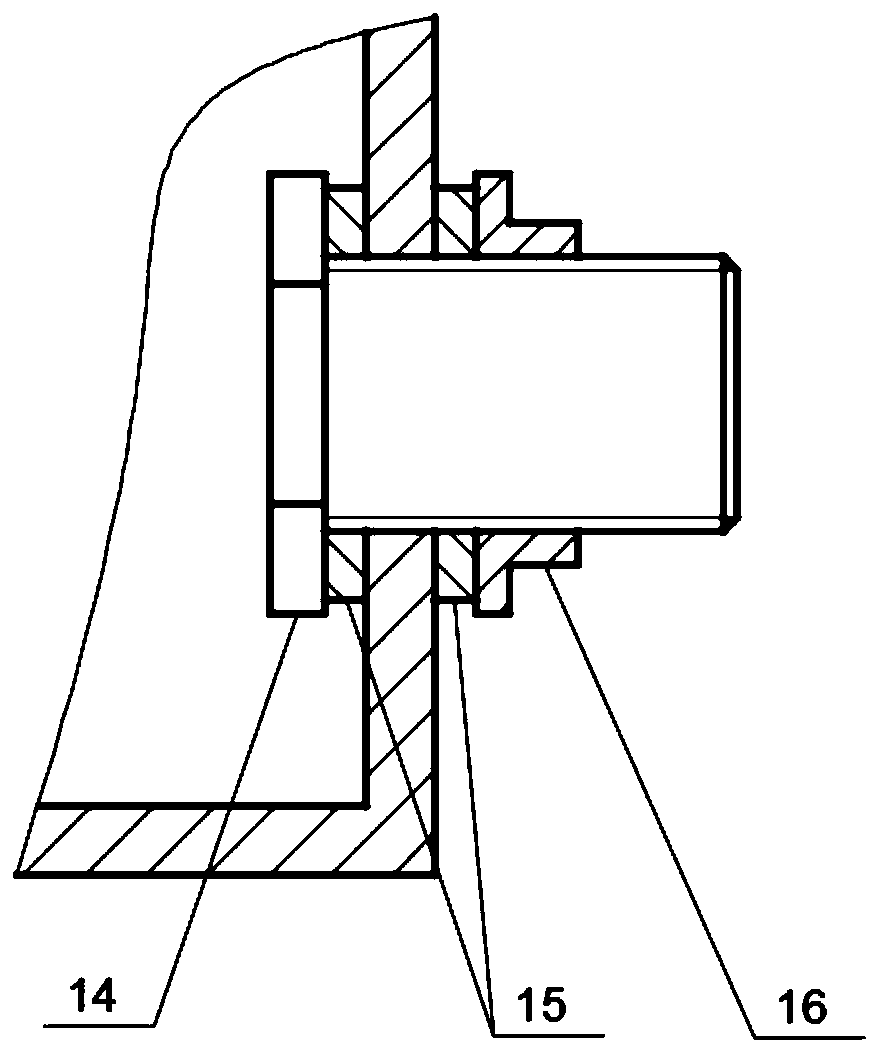

[0027] See Figure 1-2 In this embodiment, a test device for the drag reduction performance of a superhydrophobic surface includes a water tank 11, a test flow channel mechanism, a friction resistance detection mechanism, and a data processing mechanism. The test flow channel mechanism connects the water tank 11 by the water flow pipeline 8 The outlet, the water pump 10, the throttle valve 9, the flow meter 7 and the nozzle 12 are connected in sequence. The nozzle 12 is located in the water tank to form a flow circulation system. The friction resistance detection mechanism includes an elastic unit 1, a lever 2, a hinge 3 and displacement sensor 4, the hinge 3 is fixedly connected to the top of the water tank 11, the lever 2 is arranged vertically and connected to the hinge 3, the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com