A silicon carbide coaxial ultraviolet photodetector and its preparation method

A technology of electrical detectors and silicon carbide, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of reduced responsivity and quantum efficiency, achieve good device responsivity, improve efficiency, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

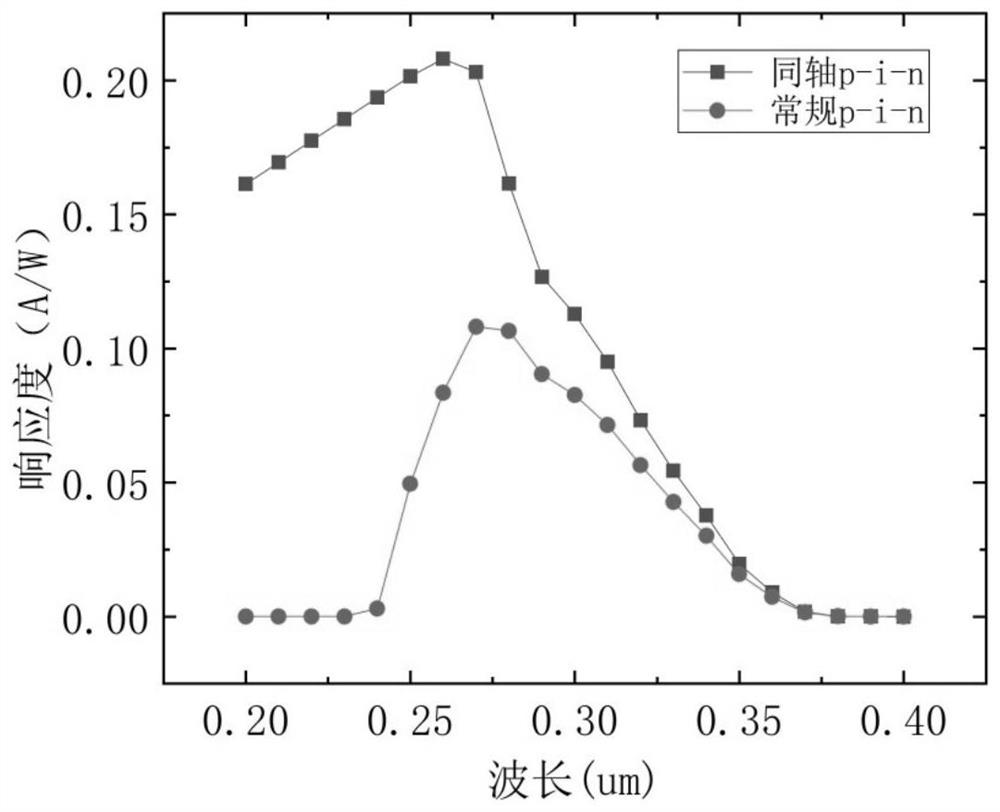

AI Technical Summary

Problems solved by technology

Method used

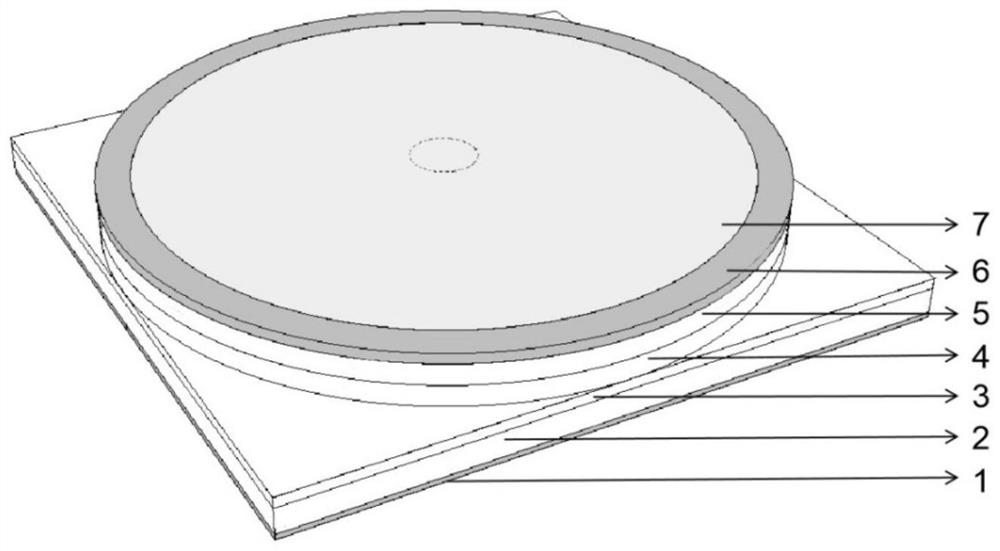

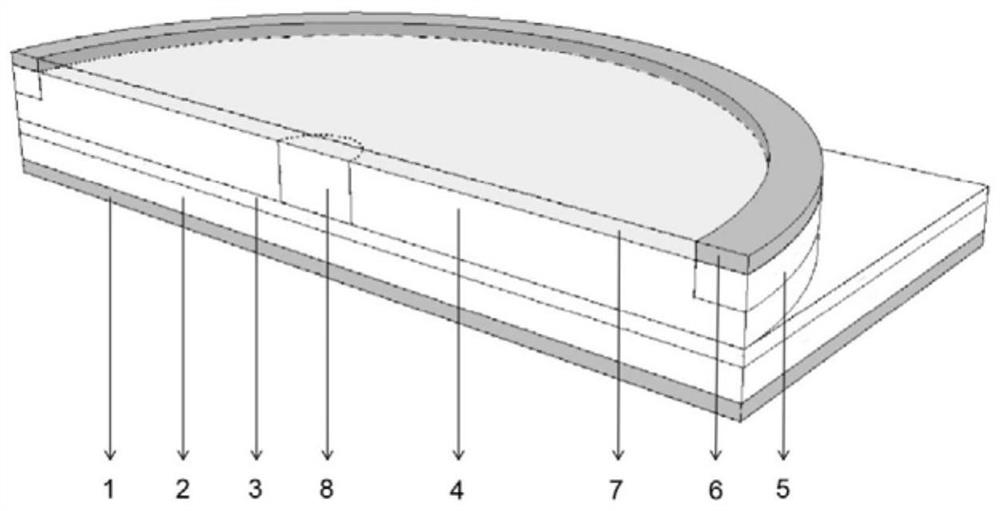

Image

Examples

preparation example Construction

[0035] The preparation method of the silicon carbide coaxial ultraviolet photodetector comprises the following steps:

[0036] 1) RCA standard cleaning is performed on the silicon carbide n+ type substrate 2;

[0037] 2) Homoepitaxially grow a silicon carbide n-type buffer layer 3 and an unintentionally doped absorber layer on the Si surface of the silicon carbide n+ type substrate 2 after RCA standard cleaning; the doping of the silicon carbide n-type buffer layer 3 Concentration can be 1×10 18 / cm 3 ~5×10 18 / cm 3 , the thickness can be 100-300nm.

[0038] 3) Etching the sample to form a cylindrical unintentionally doped absorbing layer; the etching can use a coupled plasma etching method, and the order of doping concentration of the cylindrical unintentionally doped absorbing layer can be 10 13 / cm 3 ~10 14 / cm 3 .

[0039] 4) Ion implantation and annealing to prepare a cylindrical n-type layer in the center of the cylindrical non-intentionally doped absorber layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com