Lithium-sulfur battery positive host material as well as preparation method and application thereof

A lithium-sulfur battery and host material technology, applied in battery electrodes, lithium batteries, non-aqueous electrolyte batteries, etc., can solve the problems of unfavorable large-scale production, complicated process flow, and time-consuming energy consumption, and achieve the benefits of large-scale production , Simplify the experimental process, and the effect of excellent battery performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

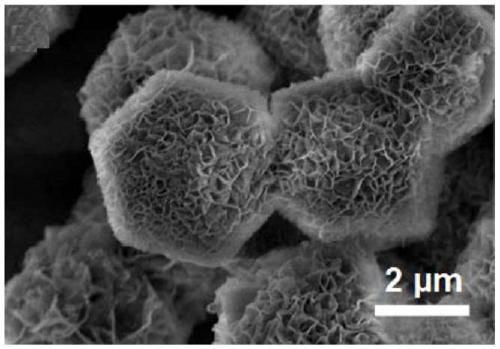

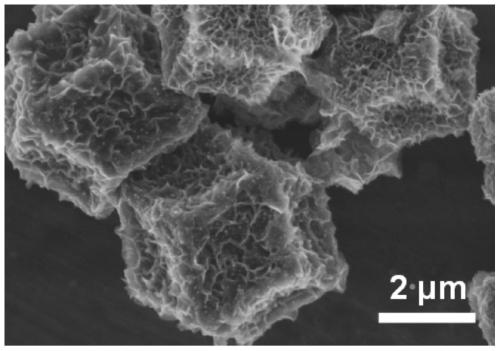

[0071] This embodiment provides a positive host material for a lithium-sulfur battery. The positive host material for a lithium-sulfur battery has a core-shell structure, and the core of the core-shell structure is a cobalt metal-organic framework (the organic ligand of the cobalt metal-organic framework is 2-methylimidazole), the shell of the core-shell structure is cobalt-nickel hydroxide doped with an organic ligand (polyvinylpyrrolidone). The particle size of the positive electrode host material of the lithium-sulfur battery is 3.3 μm, the particle size of the core of the core-shell structure is 2.0 μm, and the thickness of the shell of the core-shell structure is 0.2 μm.

[0072] The preparation method of the cathode host material of the lithium-sulfur battery comprises the following steps:

[0073] (1) Dissolve cobalt nitrate hexahydrate, nickel nitrate hexahydrate and polyvinylpyrrolidone (K30) in anhydrous methanol, put them into a magnetic rotor, and stir at 25°C unti...

Embodiment 2

[0078] This embodiment provides a positive host material for a lithium-sulfur battery. The positive host material for a lithium-sulfur battery has a core-shell structure, and the core of the core-shell structure is a cobalt metal-organic framework (the organic ligand of the cobalt metal-organic framework is 2-methylimidazole), the shell of the core-shell structure is cobalt-nickel hydroxide doped with an organic ligand (polyvinylpyrrolidone). The particle size of the positive electrode host material of the lithium-sulfur battery is 4.2 μm, the particle size of the core of the core-shell structure is 1.9 μm, and the thickness of the shell of the core-shell structure is 0.2 μm.

[0079] The difference between the preparation method of the lithium-sulfur battery cathode host material and Example 1 is that the step (1) was reacted at 90° C. for 9 hours, and the other steps were the same as in Example 1.

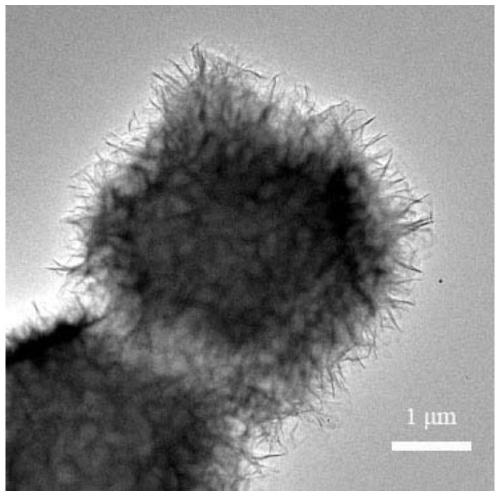

[0080] Figure 3A For the transmission electron micrograph of the precursor...

Embodiment 3

[0082] This embodiment provides a positive host material for a lithium-sulfur battery. The positive host material for a lithium-sulfur battery has a core-shell structure, and the core of the core-shell structure is a cobalt metal-organic framework (the organic ligand of the cobalt metal-organic framework is 2-methylimidazole), the shell of the core-shell structure is cobalt-nickel hydroxide doped with an organic ligand (polyvinylpyrrolidone). The particle size of the positive electrode host material of the lithium-sulfur battery is 4.2 μm, the particle size of the core of the core-shell structure is 1.8 μm, and the thickness of the shell of the core-shell structure is 0.29 μm.

[0083] The difference between the preparation method of the lithium-sulfur battery cathode host material and Example 1 is that the step (1) was reacted at 90° C. for 23 hours, and the other steps were the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com