Heat exchange and four-phase separation device

A phase separation and heat exchanger technology, applied in liquid separation, separation methods, precipitation separation, etc., can solve the problems of low mass transfer and heat transfer efficiency, device blockage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

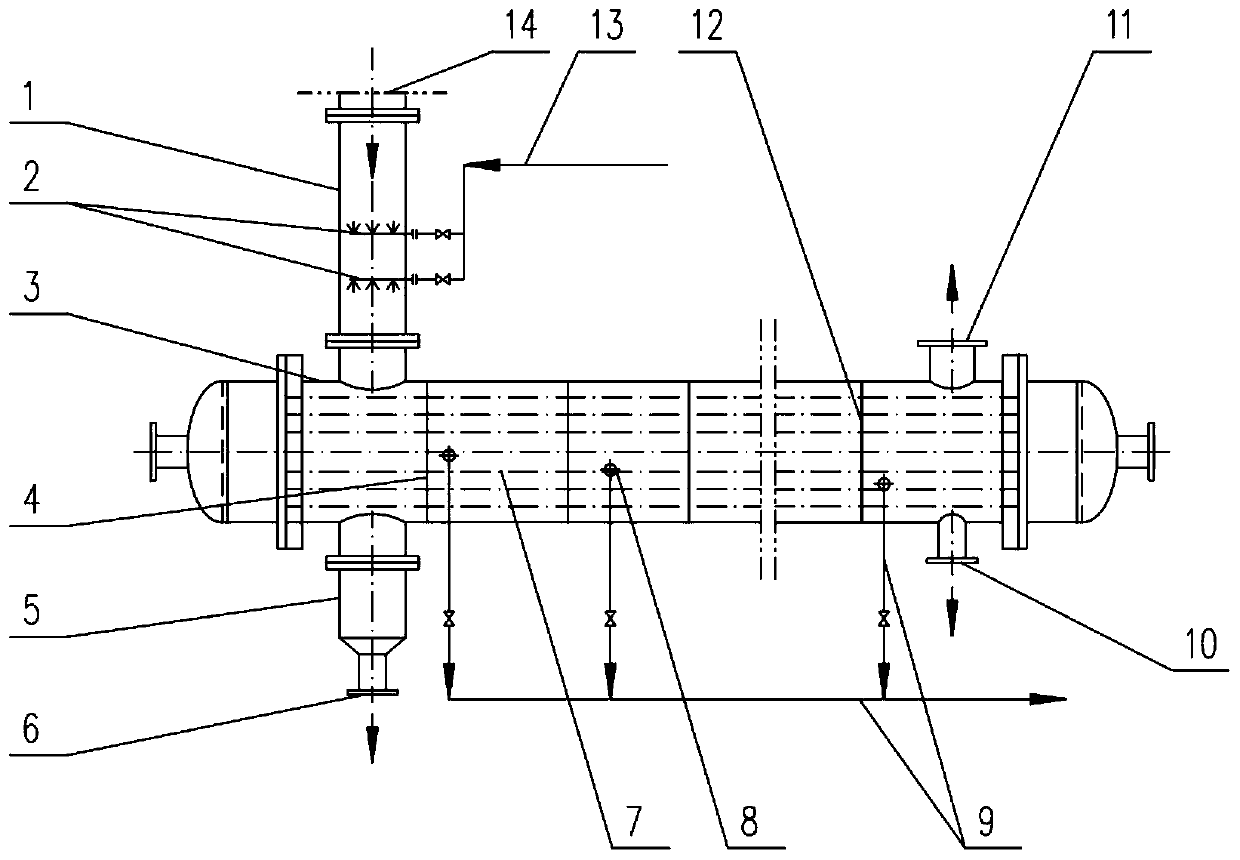

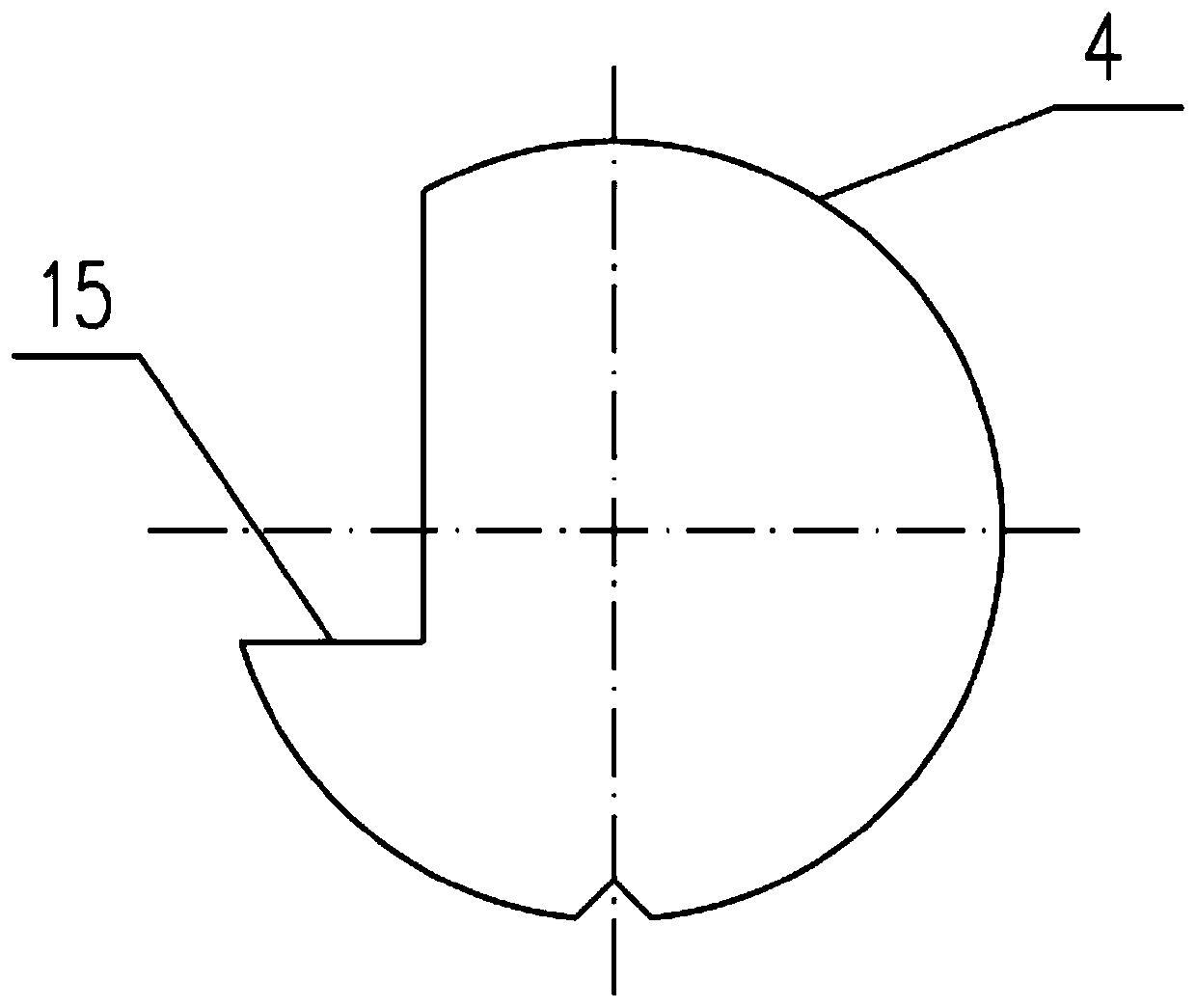

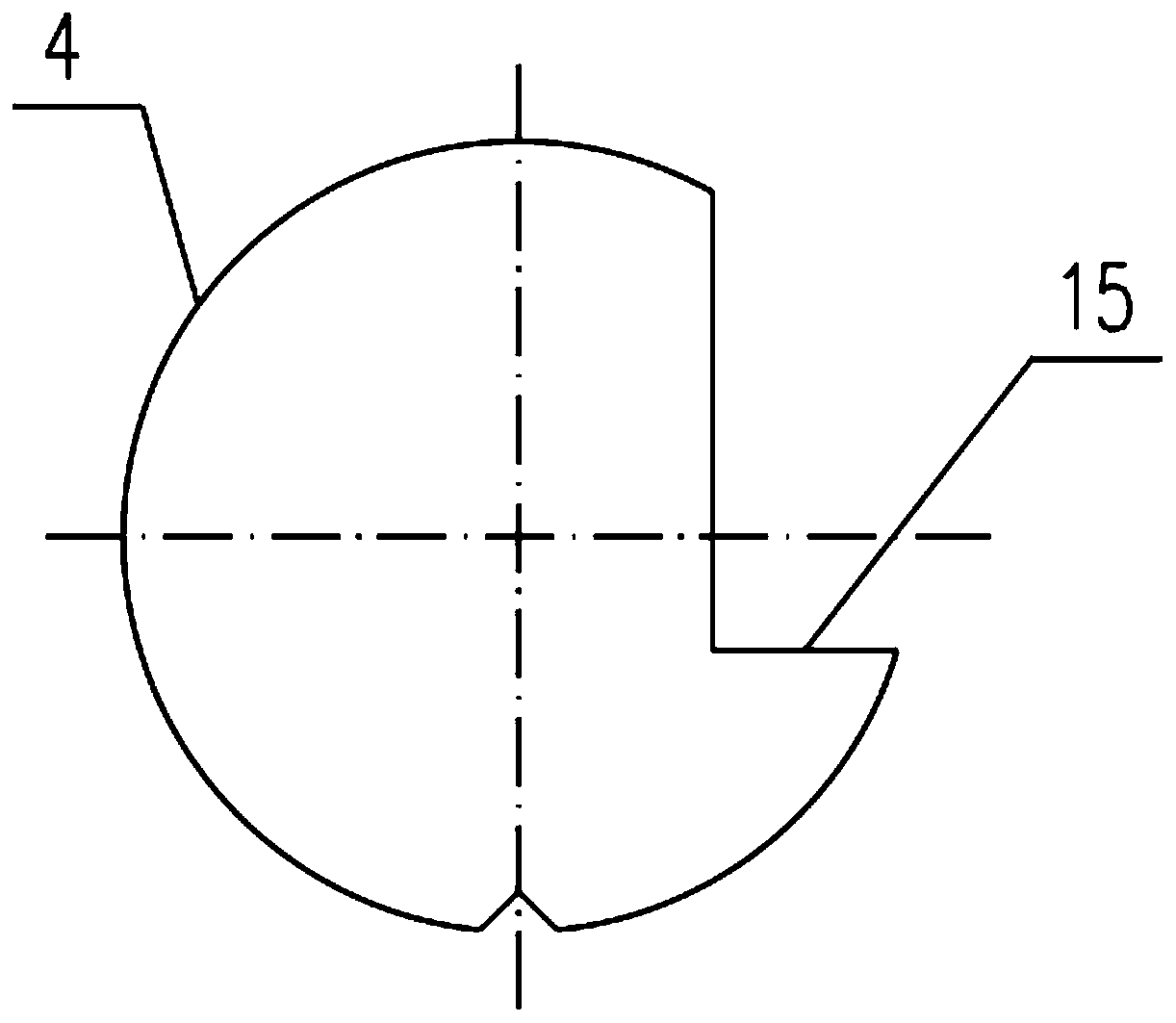

[0029] Such as Figure 1 to Figure 6 As shown, a heat exchange and four-phase separation device is a horizontal device with a slope, and the slope is 0.01. In other embodiments, the slope can be 0.05, 0.1, 0.15. The separation effect of the horizontal device with slope is better than that of the vertical device. The heat exchange and four-phase separation device includes a heat exchanger (3) and an air inlet device (1) fixedly installed at one end of the heat exchanger (3), wherein the heat exchanger (3) is provided with a heat exchange tube (7), and A number of overflow baffles I (4) and a number of overflow baffles II (12) are arranged inside the cylinder, and the overflow baffle I (4) is the first near the air inlet device (1). One baffle, overflow baffle II (12) is the remaining baffle. The cylinder of the heat exchanger (3) is provided with a number of oil production outlets (8) of different levels, and the oil production outlet (8) is connected to the oil collection pip...

Embodiment 2

[0034] Such as Figure 7 As shown, on the basis of the innovation of the first embodiment, the air inlet device (1) is arranged in the middle section of the heat exchanger (3), which will be more suitable for non-condensable gas, and the crystal separation requires longer residence time. At least two overflow baffles I (4) are required on the device. This embodiment is provided with two liquid phase outlets (10) and two gas phase outlets (11).

[0035] The working process of the present invention: the gas from the top of the rectification tower enters the gas inlet device (1) through the gas inlet (14), where mass transfer and condensation cooling are carried out, and the gas inlet device (1) contains a spray device (2), the condensed liquid is sent to the spray device (2) through the spray pipe (13) to be sprayed and fully mixed with the gas. The spray device (2) can be sprayed downwards with the gas in parallel or upwards. The gas is sprayed countercurrently. The condensed liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com