Double-tower desulfurization and denitrification system and method adopting ozone oxidation in cooperation with multi-stage circulating spraying

A technology of circulating spraying, desulfurization and denitrification, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of incomplete oxidation of NO, complex by-product components, restrictions on the popularization and application of ozone oxidation, etc. Effect of smoke phenomenon, reduction of competing reactions, reduction of equipment corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

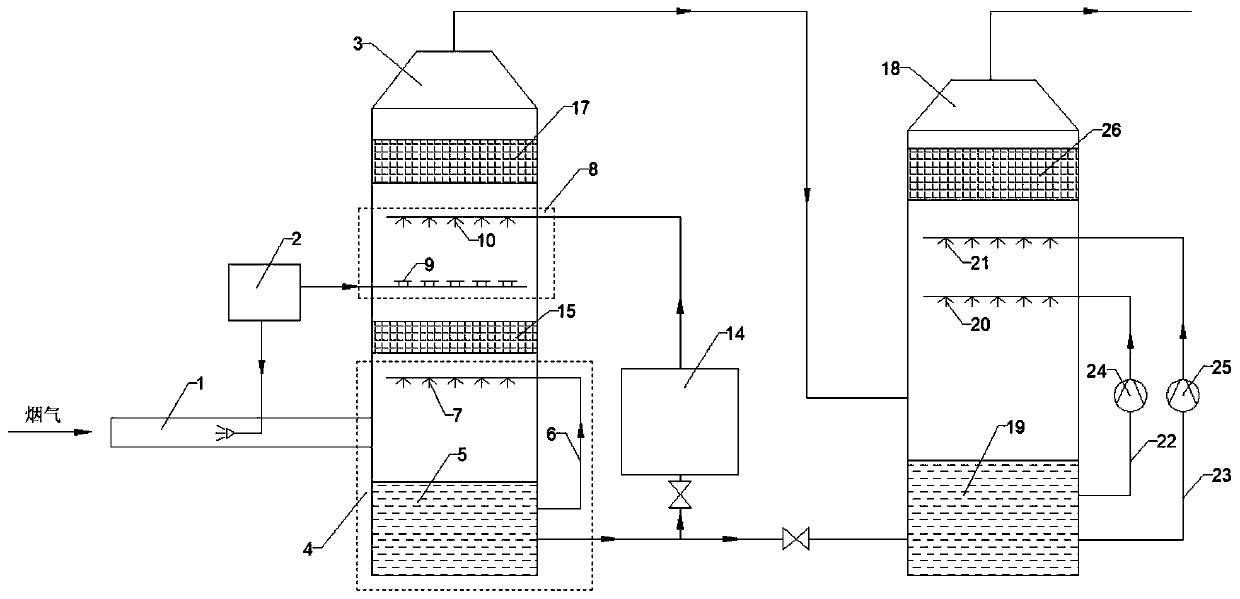

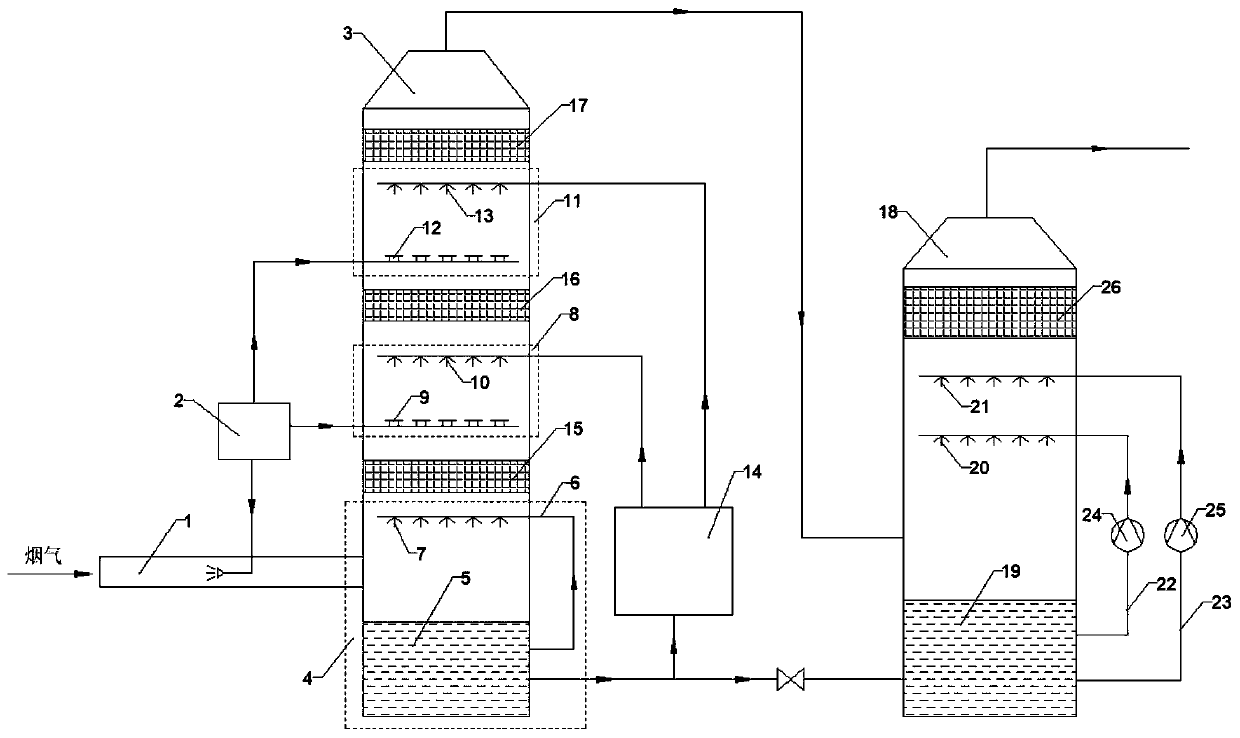

[0073] This embodiment provides a dual-tower desulfurization and denitrification system with ozone oxidation and two-stage circulating spraying. The dual-tower desulfurization and denitrification system is as follows: figure 1 As shown, it includes a desulfurization device 3 and a denitrification device 18 connected to the flue gas outlet of the desulfurization device 3. The liquid outlet at the bottom of the desulfurization device 3 is connected to the denitrification device 18, and the absorption liquid collected at the bottom of the desulfurization device 3 is passed into the denitrification device 18 as a denitrification liquid. use.

[0074] The inlet flue 1 of the desulfurization device 3 is connected to the ozone generator 2, and the ozone generator 2 is connected to the inlet flue 1 of the desulfurization device 3 through the ozone injection pipeline, and the outlet end of the ozone injection pipeline faces the flue gas intake direction , after the flue gas enters the ...

Embodiment 2

[0082] In this example, the desulfurization and denitrification system provided in Example 1 is used to desulfurize and denitrify the flue gas, and the SO in the flue gas 2 The concentration is 320mg / Nm 3 , NO in flue gas x The concentration is 220mg / Nm 3 , the processing method specifically includes the following steps:

[0083] (1) The ozone generator 2 sprays 2kg / h of ozone into the inlet flue 1, and the flue gas flows at 5000Nm 3 After the flow rate of / h enters the inlet flue 1, it contacts with ozone to oxidize. The molar ratio of ozone to NO in the flue gas is 0.5:1, and the contact time is 1s. The oxidized flue gas enters the desulfurization device 3;

[0084] (2) After the flue gas enters the desulfurization device 3, it first enters the circulating spray area 4, and in the circulating spraying area 4, the flue gas and the desulfurization liquid NaOH solution of the circulating spray are countercurrently contacted and reacted to form Na 2 SO 3 Realize initial des...

Embodiment 3

[0089] In this example, the desulfurization and denitrification system provided in Example 1 is used to desulfurize and denitrify the flue gas, and the SO in the flue gas 2 The concentration is 560mg / Nm 3 , NO in flue gas x The concentration is 260mg / Nm 3 , the processing method specifically includes the following steps:

[0090] (1) The ozone generator 2 sprays 4kg / h of ozone into the inlet flue 1, and the flue gas flows at 6000Nm 3 The flow rate of / h enters the inlet flue 1 and contacts with ozone for oxidation. The molar ratio of ozone to NO in the flue gas is 0.55:1, and the contact time is 0.7s. The oxidized flue gas enters the desulfurization device 3;

[0091] (2) After the flue gas enters the desulfurization device 3, it first enters the circulating spray area 4, and in the circulating spraying area 4, the flue gas and the desulfurization liquid NaOH solution of the circulating spray are countercurrently contacted and reacted to form Na 2 SO 3 Realize initial des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com