COC optical fiber automatic coupling and packaging device and method

An automatic coupling and packaging equipment technology, applied in laser welding equipment, welding equipment, welding equipment, etc., can solve the problems of high packaging cost, low coupling precision of tail fiber, and low product qualification rate, so as to reduce manual participation degree, reduce the probability of product damage, and improve the effect of utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0038] Aiming at the existing problems of low production efficiency, low pigtail coupling precision, high packaging cost and low product qualification rate, the invention provides a COC optical fiber automatic coupling packaging device.

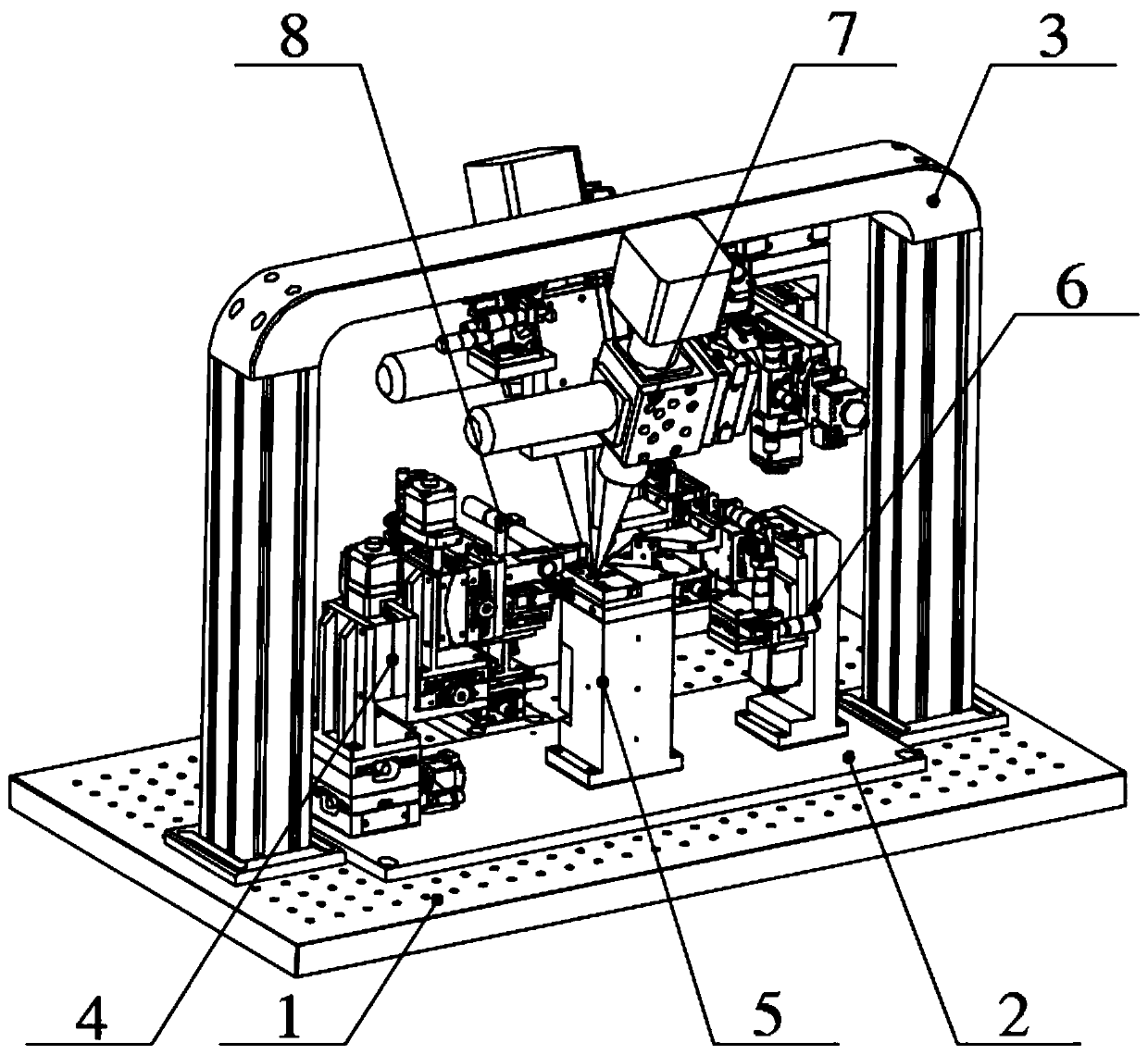

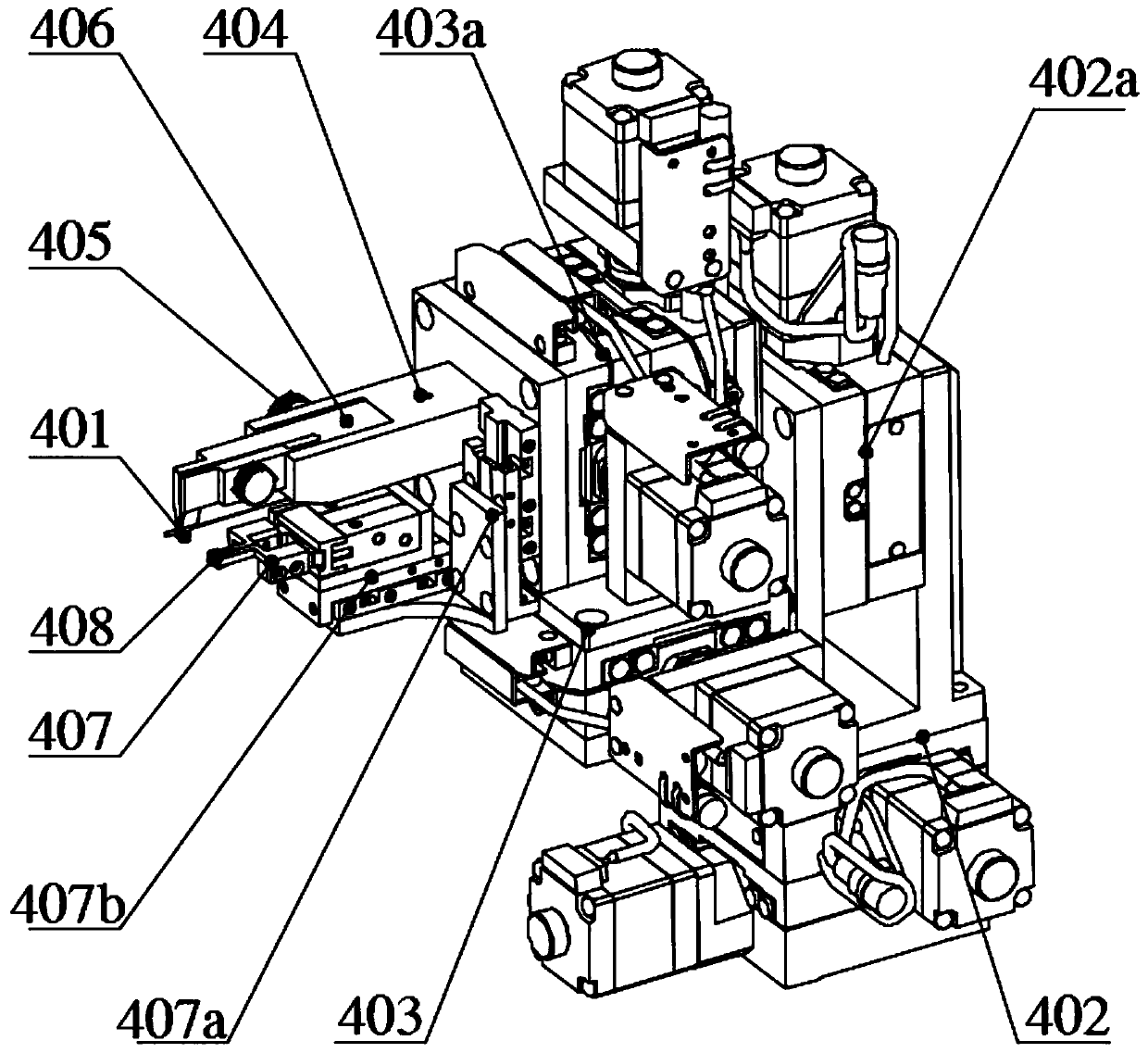

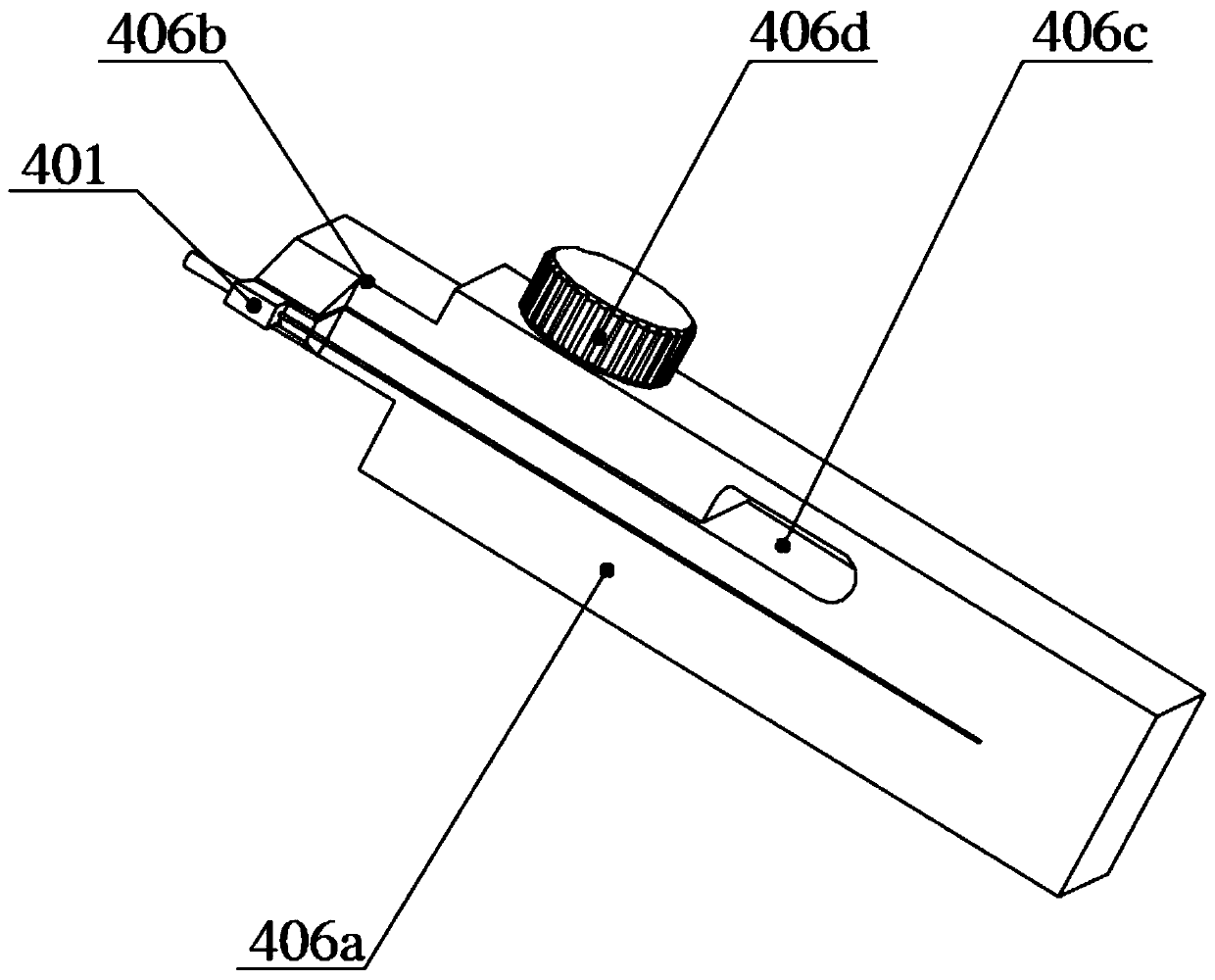

[0039] Such as figure 1 , figure 2 , Figure 4 As shown, the embodiment of the present invention provides a COC optical fiber automatic coupling packaging device, including: installation platform 1, installation plate 2, arch beam structure 3, pigtail clamping mechanism 4, base clamping mechanism 5, power supply mechanism 6. Laser welding mechanism 7 and monitoring mechanism 8; the base clamping mechanism 5 is used for clamping the COC base 501, one end of the COC base 501 is provided with a pigtail installation slot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com