Multi-row wire clamping positioning jig and multi-row wire clamping positioning method

A positioning fixture, clamping and positioning technology, applied in the direction of manufacturing tools, circuit/collector parts, auxiliary devices, etc., can solve problems such as inconvenient operation, easy bending of wires under force, troubles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

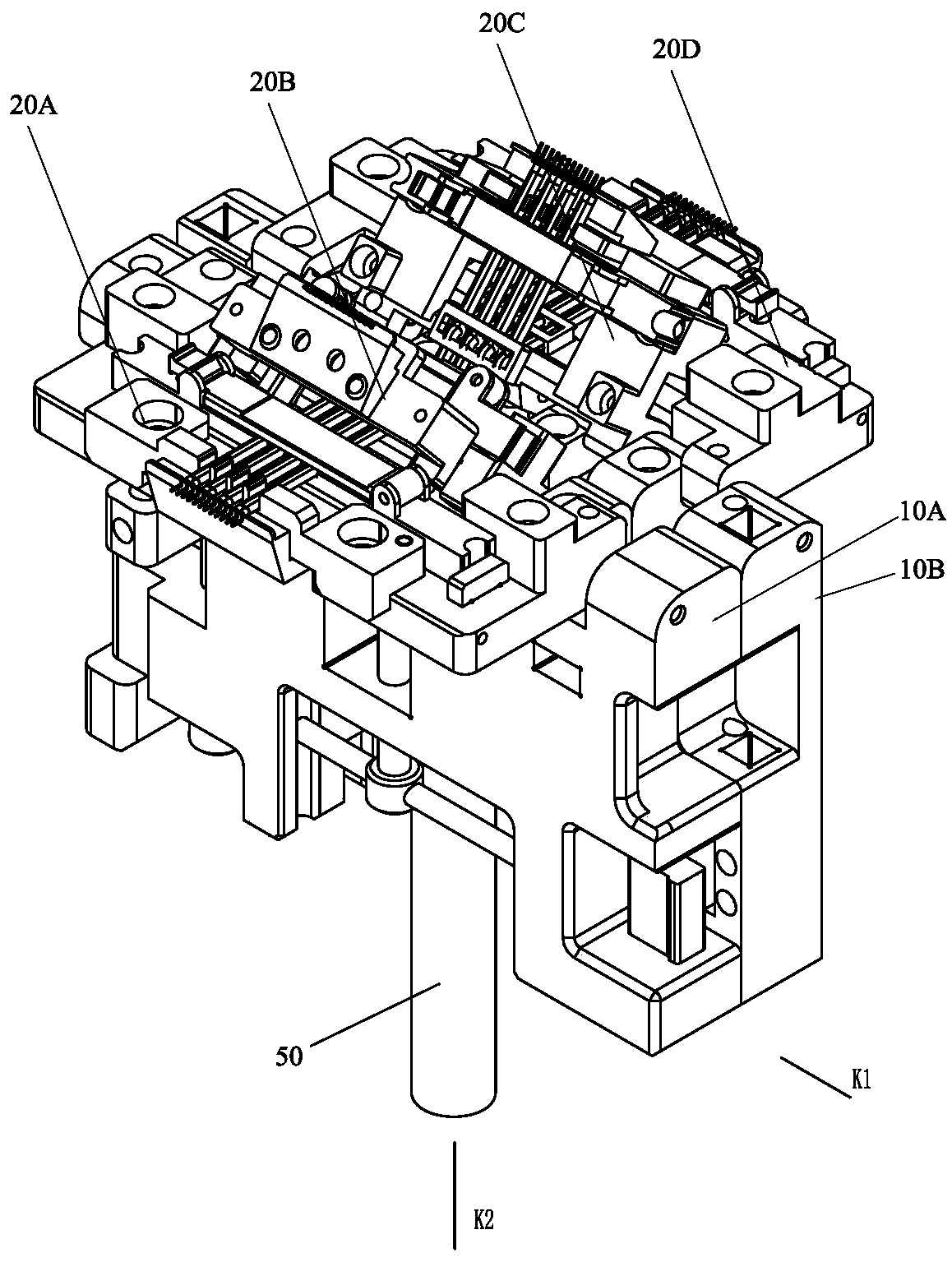

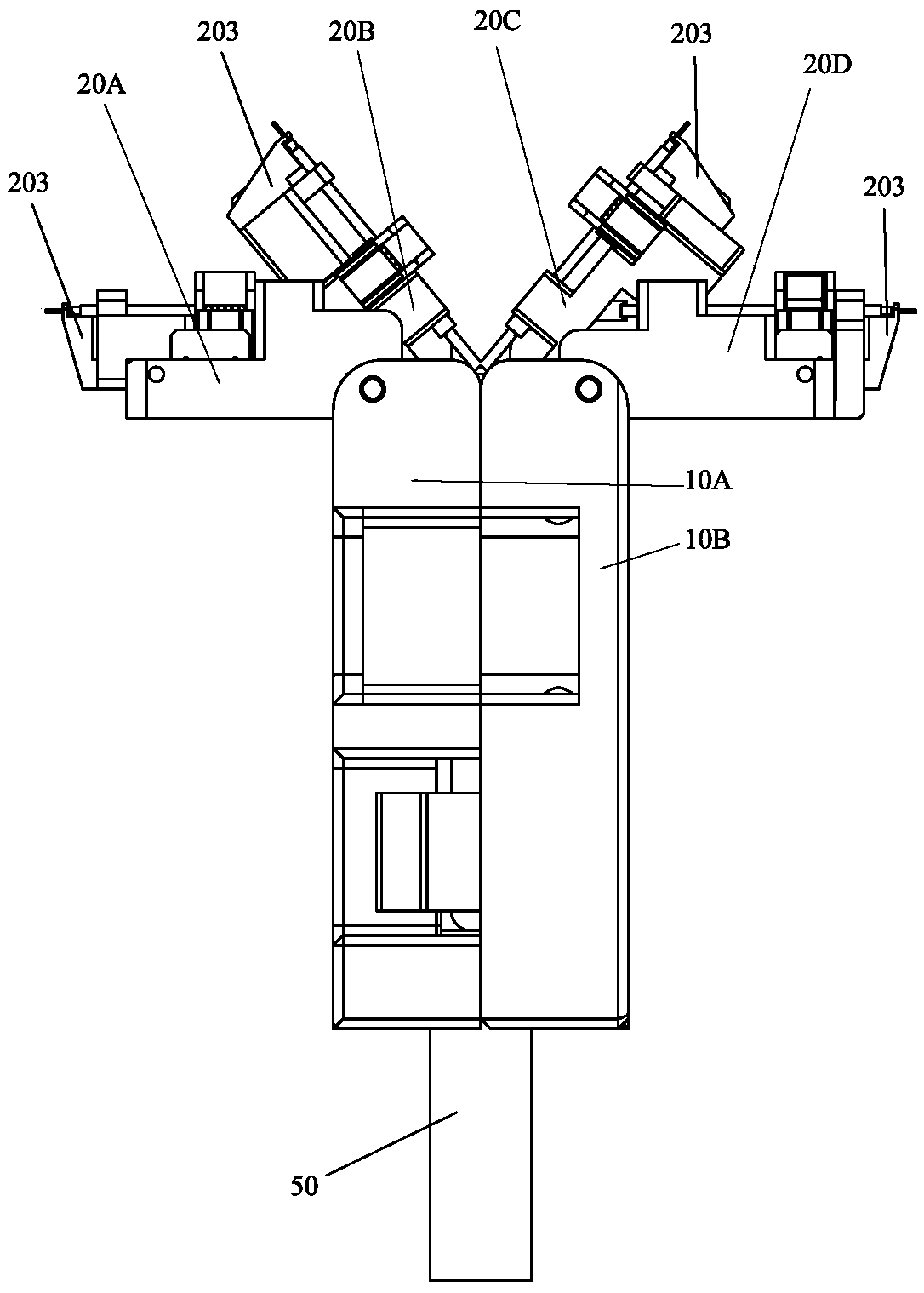

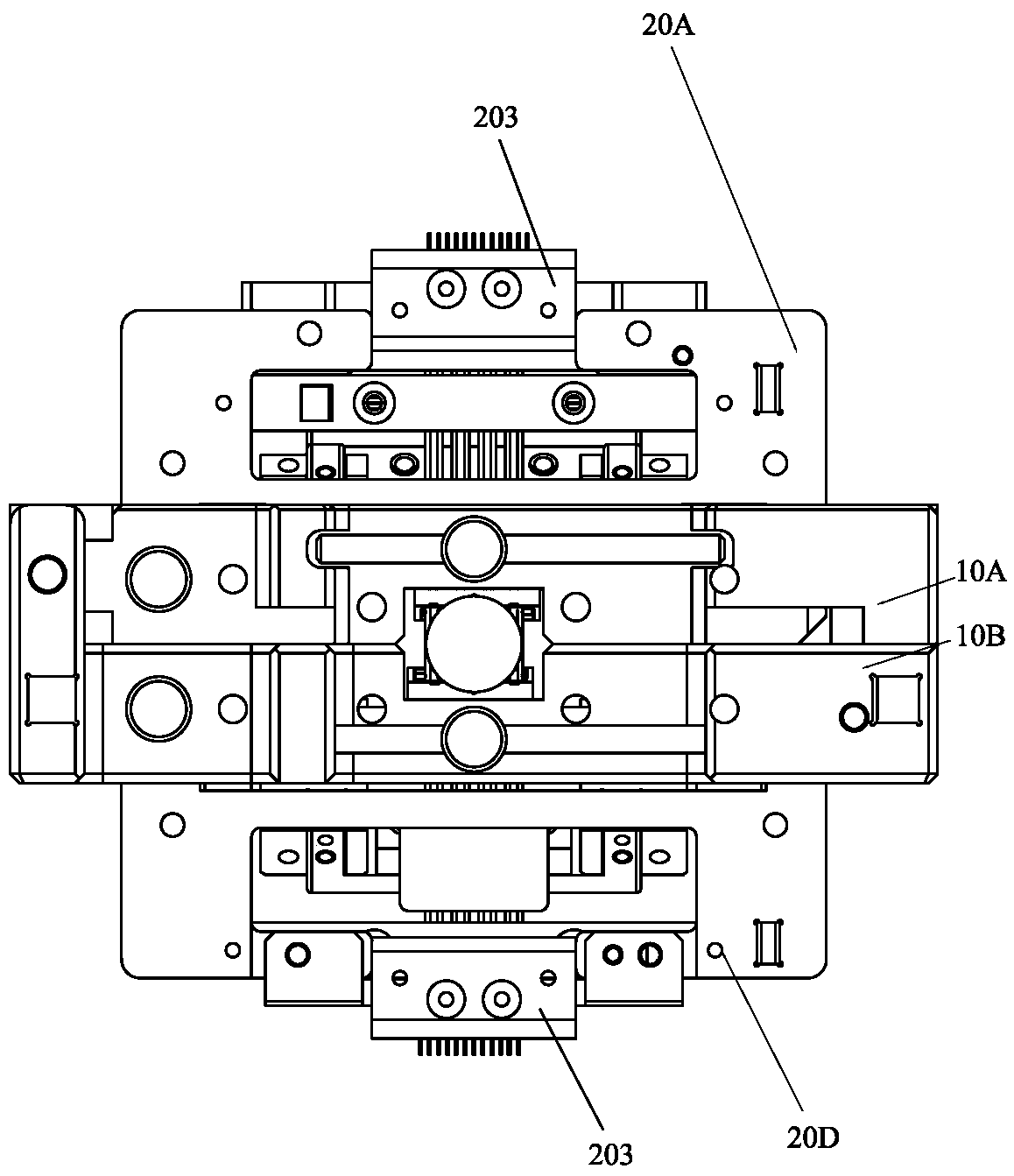

[0060] Please refer to Figure 1 to Figure 18 As shown, it shows the specific structure of the preferred embodiment of the present invention.

[0061] Such as Figure 1 to Figure 4 As shown, a multi-row wire clamping positioning jig includes a left clamping plate 10A, a right clamping plate 10B, a first positioning base 20A, a second positioning base 20B, a third positioning base 20C, a Four positioning base 20D; where:

[0062] The left clamping plate 10A and the right clamping plate 10B can be flipped along the X-axis to realize opening and closing, and after closing, a gap for wire insertion is formed between the left clamping plate 10A and the right clamping plate 10B; the first The positioning base 20A and the second positioning base 20B are respectively arranged at the head end of the left clamping plate 10A and can be flipped along the Y axis relative to the left clamping plate 10A; the third positioning base 20C and the fourth positioning base 20D are respectively a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com