An automatic identification system for motor long and short shafts, a riveting machine and an automatic identification method

An automatic identification system, technology of long and short axes, applied in radio wave measurement systems, electric components, manufacturing of motor generators, etc., can solve the problems of low output shaft mixing production quality, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

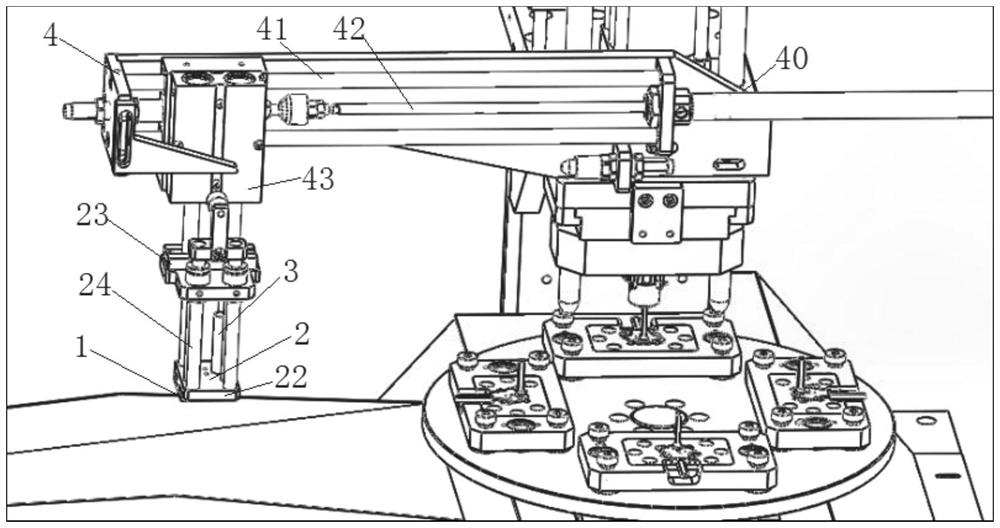

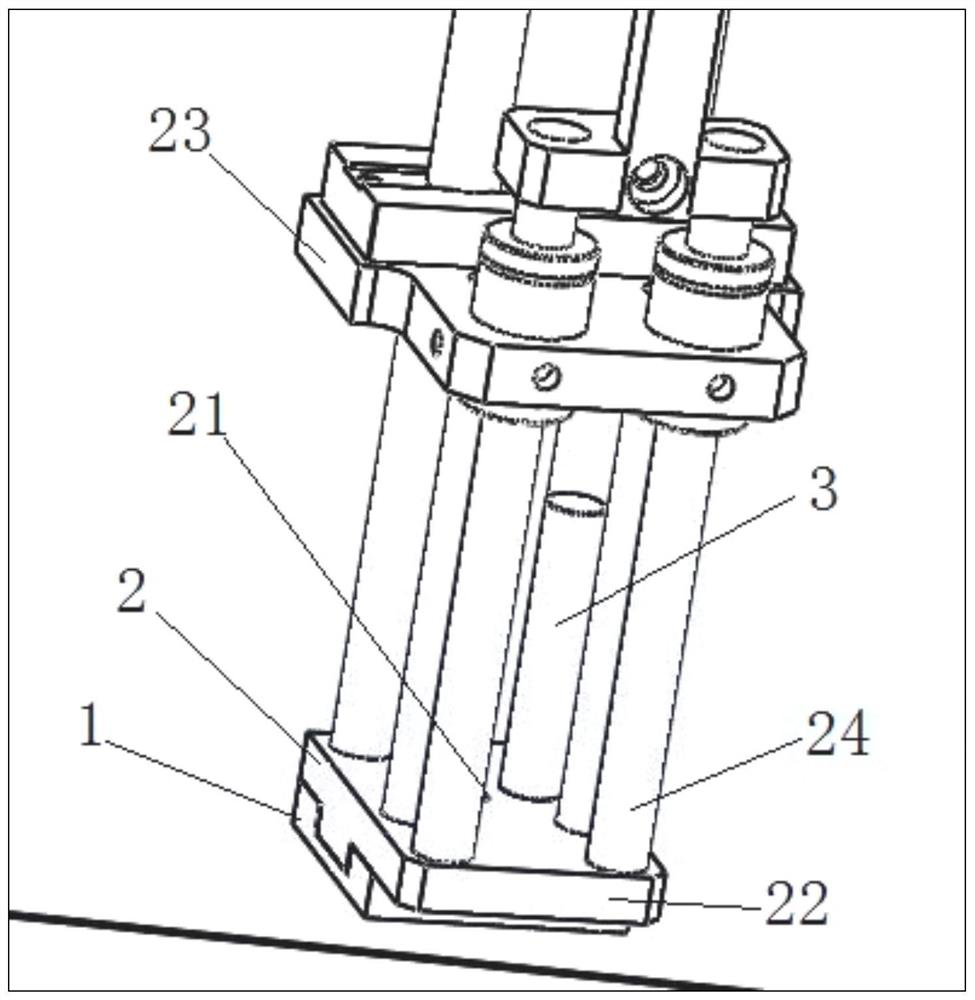

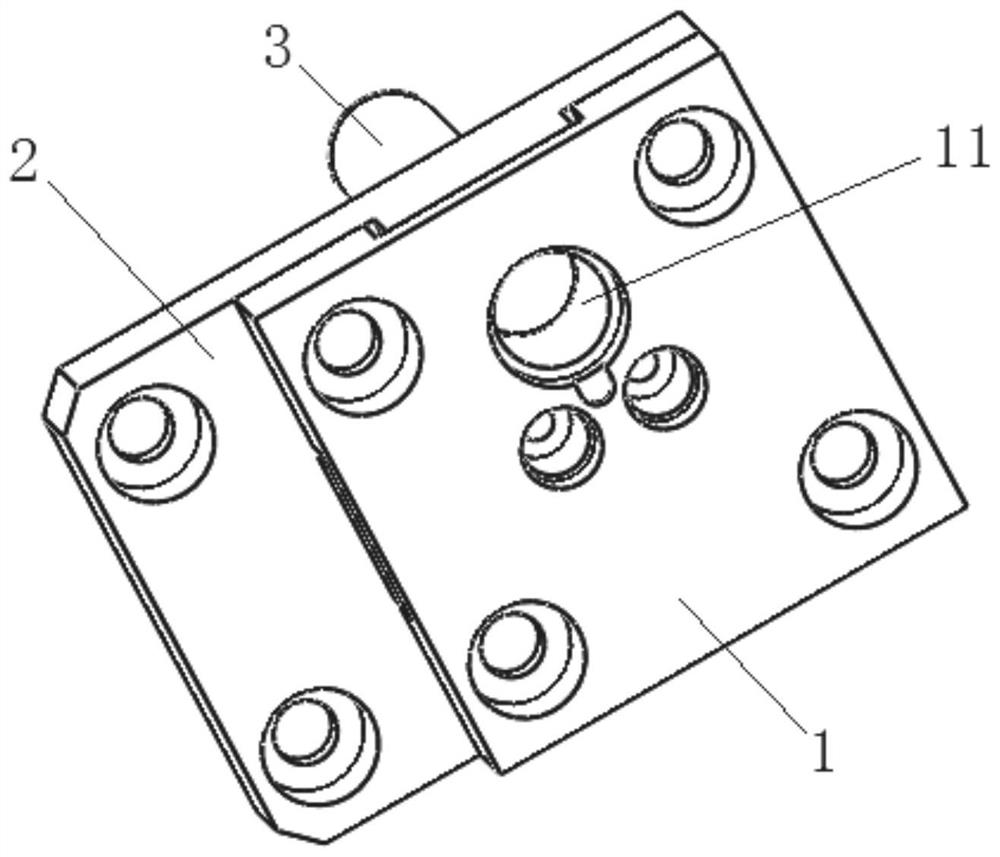

[0052] see Figure 1-4 , this embodiment provides an automatic identification system for the long and short axis of the motor. The system can be directly used in the cap riveting machine as a part of the structure of the cap riveting machine, or it can be set separately and combined with other systems to form a cap riveting machine. The automatic identification system includes a stripping plate 1, an induction base 2, a detection mechanism 3, a material retrieving mechanism 4, a data processor and a controller.

[0053] The stripping plate 1 is provided with a positioning through hole 11 for the positioning of the output shaft of a motor product. The stripping plate 1 can adopt the existing stripping plate, and its function is to provide positioning for the motor product, that is, the motor product can be positioned and transported to the riveting position under the action of other structures for riveting cover. Other holes are also provided on the stripper plate 1, and these...

Embodiment 2

[0068]This embodiment provides an automatic identification system for the long and short axes of a motor. On the basis of Embodiment 1, a weighing sensor is added to the system, and the weighing sensor belongs to the detection mechanism 3 . The load cell is installed on the stripping plate 1, and is used to detect the motor weight of the motor product. When the shaft length is within the preset length range and the radius is within the preset radius range, the controller is also used to judge whether the weight of the motor is a preset weight, and if so, drive the reclaiming mechanism to rivet the motor product; The weight of the product does not meet the standard, and the stripping plate 1 is driven to strip the motor product through the material taking mechanism. The load cell can detect the weight of the motor product and realize the weighing function. When the output shaft, length and radius of the motor meet the standards, the controller will also judge whether the weigh...

Embodiment 3

[0070] This embodiment provides a cap riveting machine, which includes the motor long and short axis automatic identification system in embodiment 1 or embodiment 2, and of course may also include a riveting platform, a material storage mechanism, and the like. The automatic identification system is used to detect the output shaft of the motor product and identify the signal of the motor product. When the motor model needs to be riveted, the controller will transport the motor product to the installation station of the riveting platform through the feeding mechanism 4, cover the motor product, and rivet the cover plate and the casing Together. The material storage mechanism is used to store the motors completed by riveting caps, and can also store those motor products that do not match the model. The riveting machine of this embodiment can avoid manual assembly of the motor, on the one hand, reduce the labor intensity, and on the other hand, can improve the riveting power and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com