Display screen interlayer defect detection method and system

A defect detection and display technology, which is applied in phase influence characteristic measurement, image data processing, instruments, etc., can solve the problems of high cost, slow detection speed, and high precision requirements, and achieve low cost, high reliability and durability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

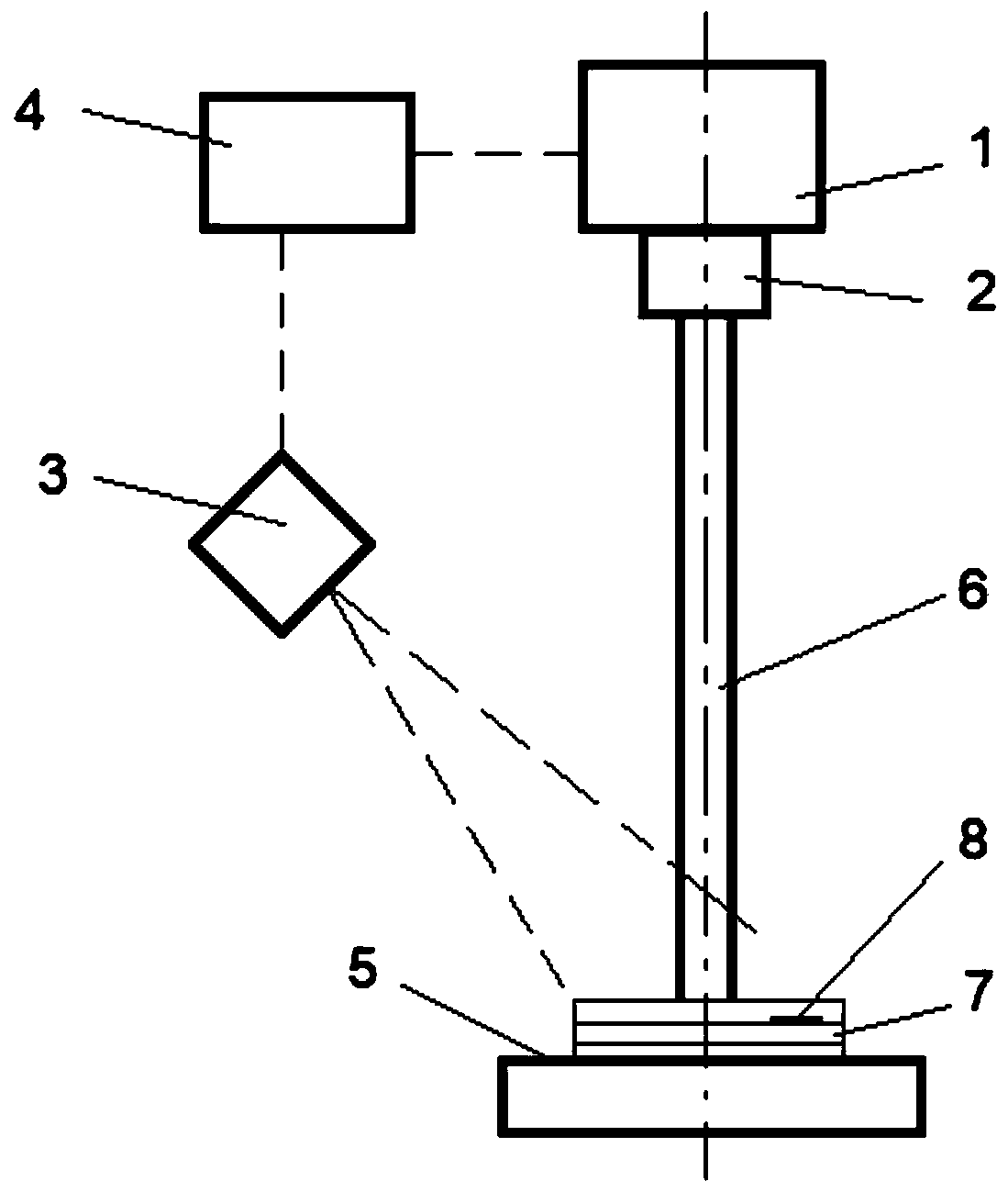

[0044] The present invention provides an embodiment, such as figure 1 As shown, the present invention provides a method for detecting interlayer defects of a display screen, comprising the following steps:

[0045] S1: Project N grating fringes with different phases to the reference plane 5 in one period, collect N reference fringe images with corresponding phases, and obtain the reference plane phase image according to the N reference fringe images;

[0046] S2: Place the display screen 7 with a transparent interlayer on the reference plane 5, project N grating fringes with different phases to the display screen 7 in one cycle, collect N detection fringe patterns with corresponding phases, and use the N detection fringes Figure to obtain the detection plane phase diagram;

[0047] S3: Subtract the detection plane phase map from the reference plane phase map to obtain a phase difference image, and obtain the height distribution of the defect area 8 on the reference plane 5 ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com