Enhanced nickel plating process

A plating and nickel alloy technology, applied in metal material coating process, liquid chemical plating, electroplating to produce magnetic layers, etc., can solve problems such as poor rigidity and flatness, HDD disc chatter, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

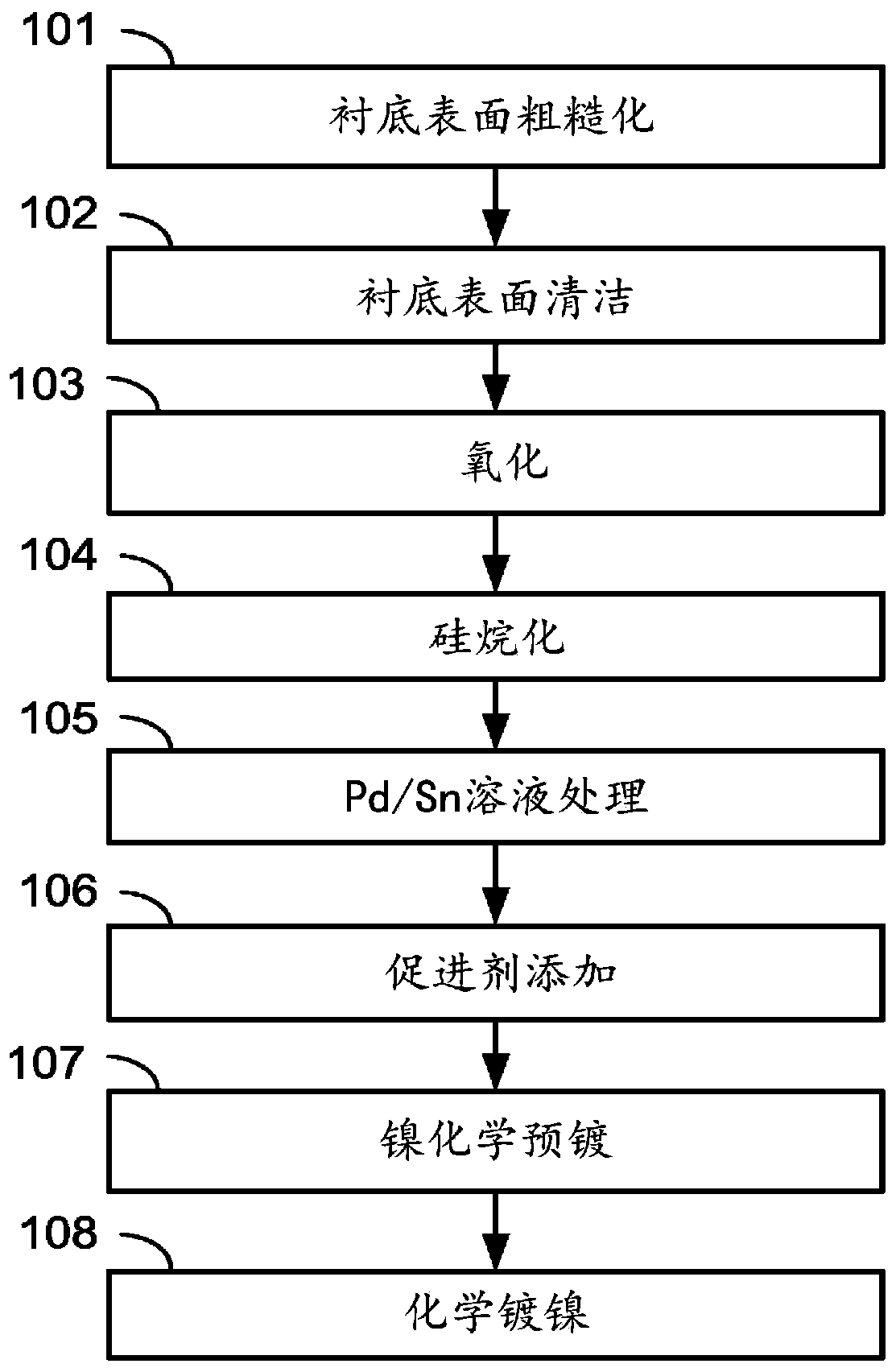

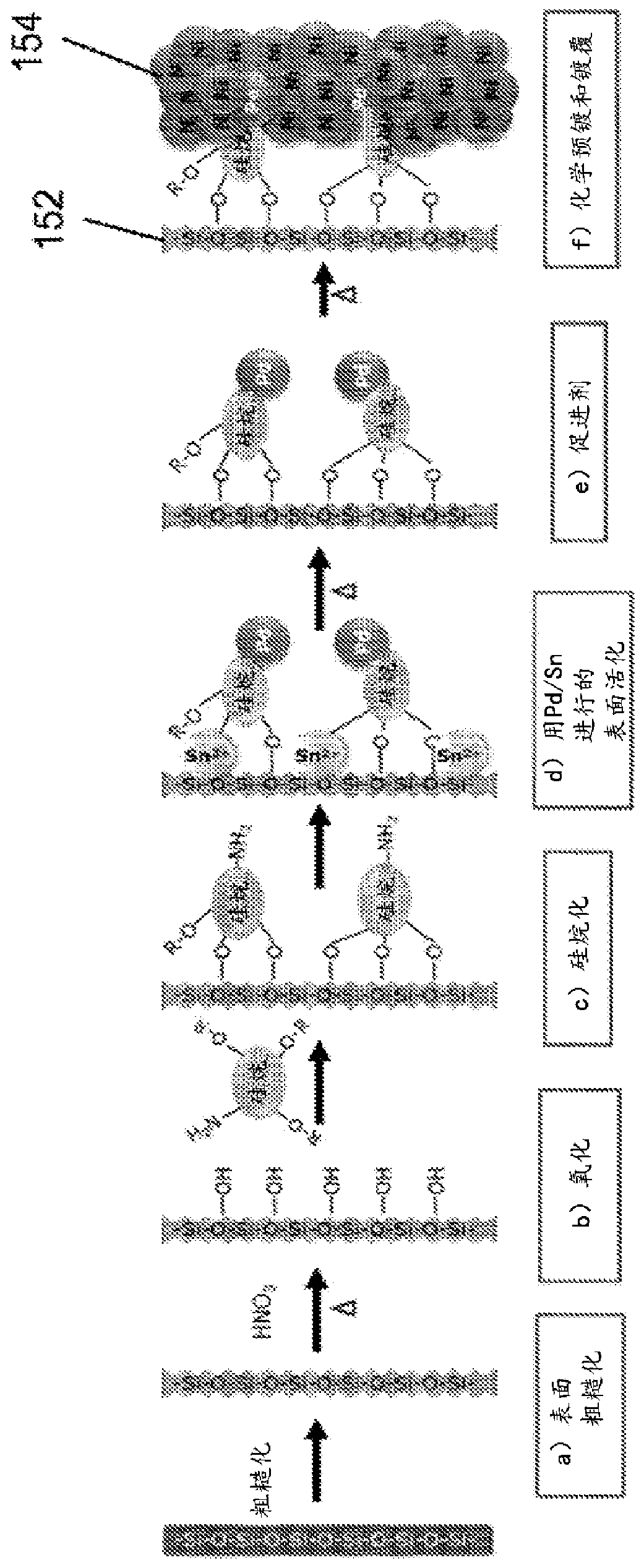

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1: ENP process

[0050] In one embodiment, the ENP process described herein is performed under the conditions shown in Table 1 below.

[0051] Table 1

[0052]

Embodiment 2

[0053] Example 2: Effect of Surface Roughening

[0054] Sodium borosilicate glass surfaces were subjected to different treatments in order to determine the effect of surface roughening on the process of the invention. Surfaces were treated with CMP, grit blasting, ammonium bifluoride, or combinations thereof, and then plated as described in Example 1 above. After ENP, the adhesion of the magnetic layer to the glass surface was tested using a cross cut tape test (ASTM D3359). The results are shown in Table 2 below.

[0055] Table 2

[0056] CMP sandblasting only Dicyandiamide only result - - - Magnetic layers are stripped prior to testing - - + Magnetic layers are stripped prior to testing - + - pass + - - pass + + pass + - + Magnetic layers are stripped prior to testing

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com