Method for improving meat product flavor

A meat product and flavor technology, applied in the field of meat and meat product processing, can solve the problems of too many late products, affecting the flavor of meat products, high reaction temperature, etc., and achieve the effect of easy popularization and use, easy operation and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

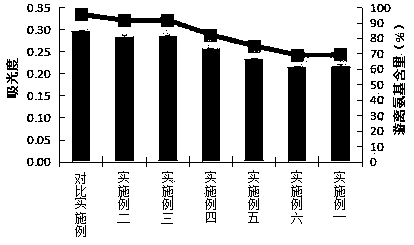

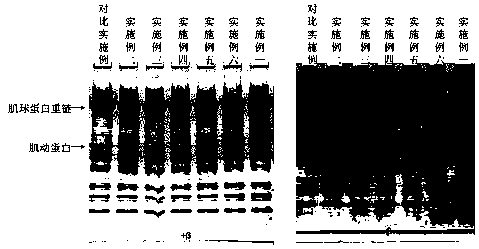

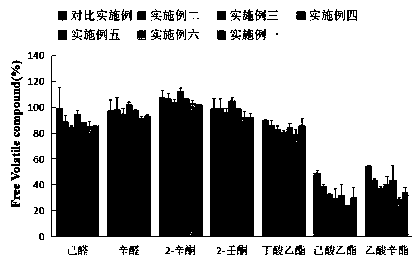

Examples

Embodiment 1

[0021] Example 1: Preparation of beef myofibrillar protein glycosylation

[0022] (1) Pretreatment: Wash the longissimus dorsi of fresh beef with distilled water, remove the tendon and process it into 2 cm 3 Meat cubes, drained.

[0023] (2) Extraction of beef myofibrillar protein:

[0024] ① Add 4 times the volume of Solution A to the pretreated meat, beat for 3 times, 15 s / time, and pour it into four 500mL centrifuge bottles on average. Homogenize each bottle twice, 15 s / time; pour a layer of gauze into 4 centrifuge bottles on average, and balance with a balance. Centrifuge (2000 g, 15 min, 4°C), discard the supernatant.

[0025] ②Add about 4 times the volume of Solution A to each bottle, stir evenly with a spoon, homogenize (twice for each bottle, 15 s / time), balance, centrifuge (2000 g, 15 min, 4°C), and discard the supernatant.

[0026] ③ Add about 4 times the volume of Solution A to each bottle, stir evenly, homogenize (twice per bottle, 15 s / time), balance, centrifu...

Embodiment 2

[0042] Embodiment 2: Steps (1), (2) and (3) are the same as Example 1.

[0043] (4) Glycosylation of beef myofibrillar protein: Mix the 6 mg / mL protein solution prepared in step (3) with 192 mg glucose (that is, the mass ratio of protein to glucose is 1:1), shake and dissolve; the sample The medium was filled with nitrogen to prevent protein oxidation and microbial contamination; the mixed protein solution was incubated at 40°C for 12 h to obtain glycosylated beef myofibrillar protein.

Embodiment 3

[0044] Embodiment 3: Steps (1), (2) and (3) are the same as Example 1.

[0045] (4) Glycosylation of beef myofibrillar protein: Mix the 6 mg / mL protein solution prepared in step (3) with 576 mg glucose (that is, the mass ratio of protein to glucose is 1:3), shake and dissolve; the sample The medium was filled with nitrogen to prevent protein oxidation and microbial contamination; the mixed protein solution was incubated at 40°C for 12 h to obtain glycosylated beef myofibrillar protein.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com