Plasma suppression method for high-power laser welding

A technology of laser welding and plasma, which is applied in laser welding equipment, welding equipment, manufacturing tools, etc., can solve problems that affect the service life of welding quality equipment, achieve the goals of reducing plasma clusters, stable and good welding, and improving work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

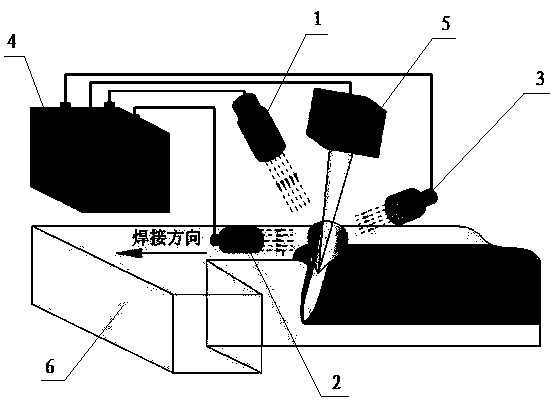

[0016] A high-power laser welding plasma suppression method, a controller 4, the upper end of the controller is respectively connected with the laser generator 5, the air injection device A1, the air injection device B2, and the suction device 3, and the air injection device A is connected along the laser The gas is injected in the direction of beam conduction, and is coaxial or paraxial with the laser beam. The welding process continuously provides shielding gas. The gas injection device B is arranged laterally to the plasma cluster, and the gas is injected laterally. The suction The gas device is distributed on the opposite side of the gas injection device B, and is mainly used to absorb plasma clusters.

Embodiment 2

[0018] According to the high-power laser welding plasma suppression method described in embodiment 1, the controller adjusts the gas flow in real time according to the size of the laser power and the material of the welding workpiece, the injection gas is an inert gas, the higher the laser power, the higher the injection gas And the higher the flow rate of the absorbing gas, the plasma clusters generated by welding will be reduced or deviated from the laser transmission path, reducing the impact on laser energy and achieving stable welding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com