Multi-transmission-mechanical-hand photoetching machine based on neural network and cooperative control system of photoetching machine

A neural network and collaborative control technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of delayed manipulator information interaction and collaborative work efficiency, lack of processing power and fault tolerance, product cost and space waste, etc., to achieve Improved robustness and adaptability, improved stability and accuracy, and improved communication time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

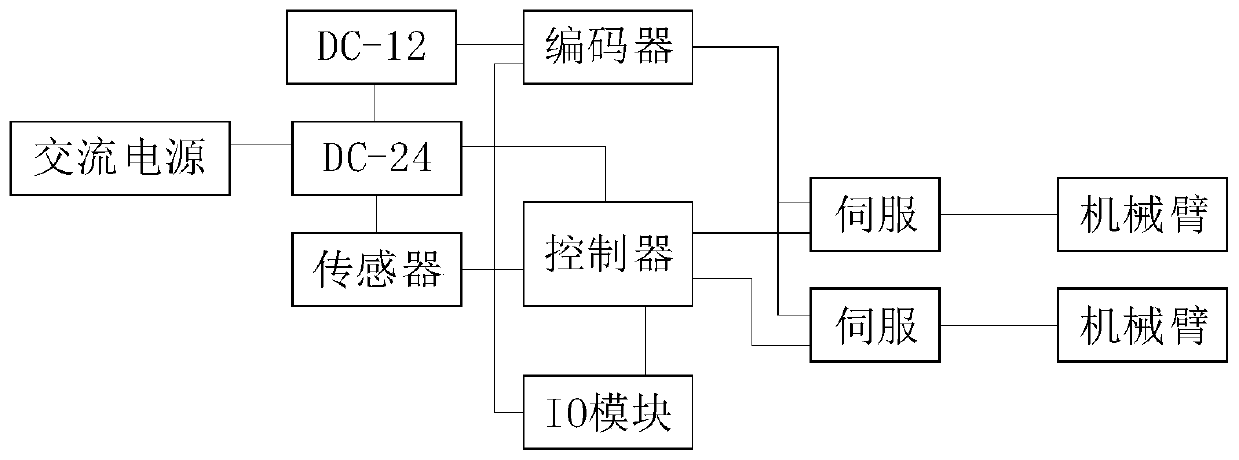

[0031] A neural network-based multi-transmission manipulator lithography machine, including a body, a controller, a data input and output port io module, a servo motor, a robotic arm, an encoder, a voltage mode controller, an AC power supply, and a sensor. The controller is connected to the servo motor, Data input and output port io module, voltage mode controller, sensor connection, controller, data input and output port io module, servo motor, encoder, voltage mode controller, AC power supply, sensor installed inside the body, mechanical arm and body connection, servo The connection between the motor and the mechanical arm, the connection between the servo motor and the encoder, the connection between the encoder and the voltage mode controller, the connection between the voltage mode controller and the AC power supply, the sensor, the connection between the encoder and the data input and output port io module, the connection between the controller and the data input and outpu...

Embodiment 2

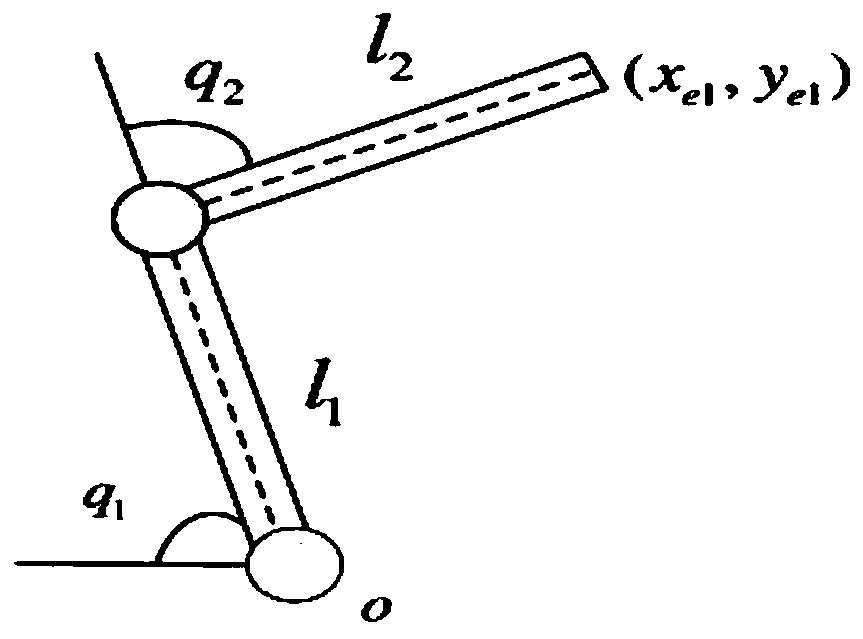

[0033] As the arm makes inferences for two, it is elaborated:

[0034] Such as figure 2 As shown, the dynamic equation of a single mechanical arm is mainly the conversion relationship between the joint control q and the output torque τ, l i i=1,2 is the length of the i-th link of the mechanical arm, q i i=1,2 is the joint control angle, and the dynamic equation of a single manipulator is obtained through the Lagrange-Euler formula:

[0035]

[0036] Then deduce the dynamic equation equation of multiple manipulator cooperative control system

[0037] M(x 0 ,q)x 0 +C(x 0 ,x 0 ,q,q)x 0 +G(x 0 ,q)=τ

[0038] According to the multi-manipulator cooperative dynamics model equation, the multi-manipulator cooperative control system designed on this basis can control the movement of a single manipulator, and is also compatible with the coordinated movement of two manipulators and a single manipulator;

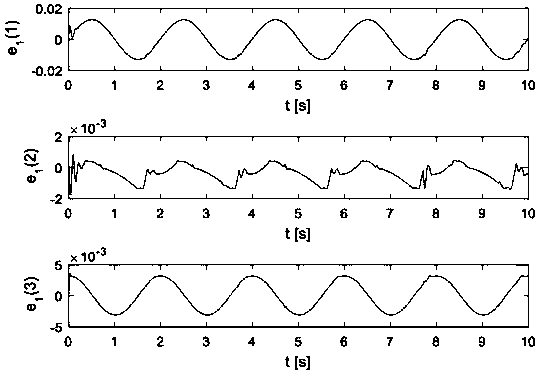

[0039] The RBF neural network is a radial basis function RBF neural ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com