Modification method of temperature-sensitive hydrogel material, modified temperature-sensitive hydrogel material and biological 3D printing ink

A temperature-sensitive hydrogel, hydrogel technology, applied in the direction of additive processing, can solve the problems of extrusion swelling, poor mechanical strength of hydrogel, structural collapse, etc., and achieve the effect of improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

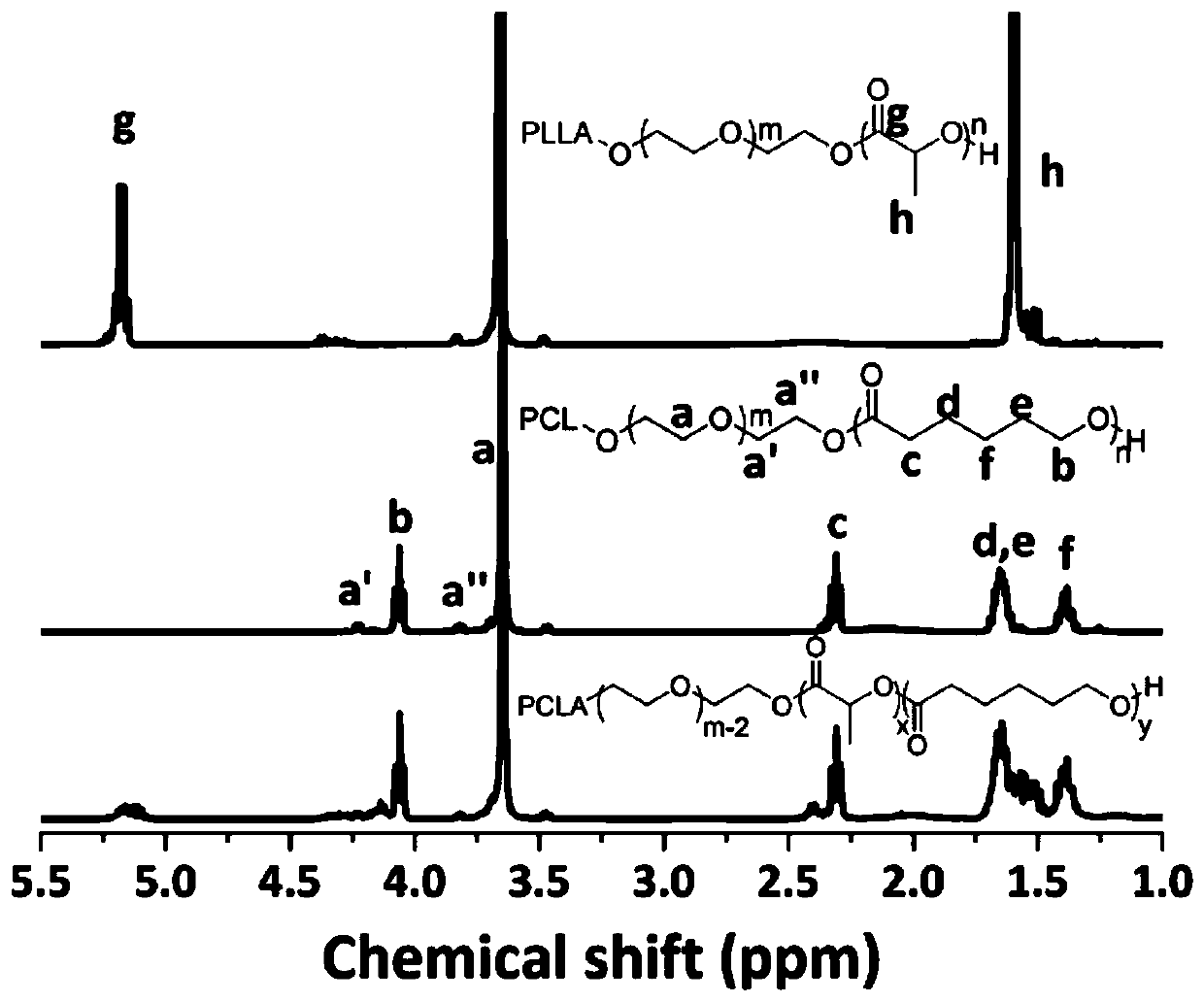

[0070] The preparation method of polycaprolactone-polyethylene glycol-polycaprolactone is as follows:

[0071] Mix polyethylene glycol and ε-caprolactone in the presence of a catalyst and react at 130-150°C for 6-10 hours. The reaction formula is as follows:

[0072]

[0073] After the reaction is completed, it is quenched below -20°C and terminated with CH 2 Cl 2 Ultrasonic dissolution, the dissolved CH 2 Cl 2 The solution was added dropwise to glacial ether for settling, and the white product gradually precipitated out. The mixture was suction-filtered and washed at least twice with anhydrous ether, and the resulting product was vacuum-dried to obtain a white solid powder.

[0074] Optionally, the catalyst includes stannous isooctanoate.

[0075] Optionally, the polyethylene glycol has a molecular weight of 4000-10000 Da.

[0076] Optionally, the molar ratio of polyethylene glycol to ε-caprolactone is 1: (35-50).

[0077] Optionally, the reaction environment is an ...

Embodiment 1

[0089] The embodiment of the present application provides a method for modifying a temperature-sensitive hydrogel material, and a modified temperature-sensitive hydrogel material, which includes the following steps:

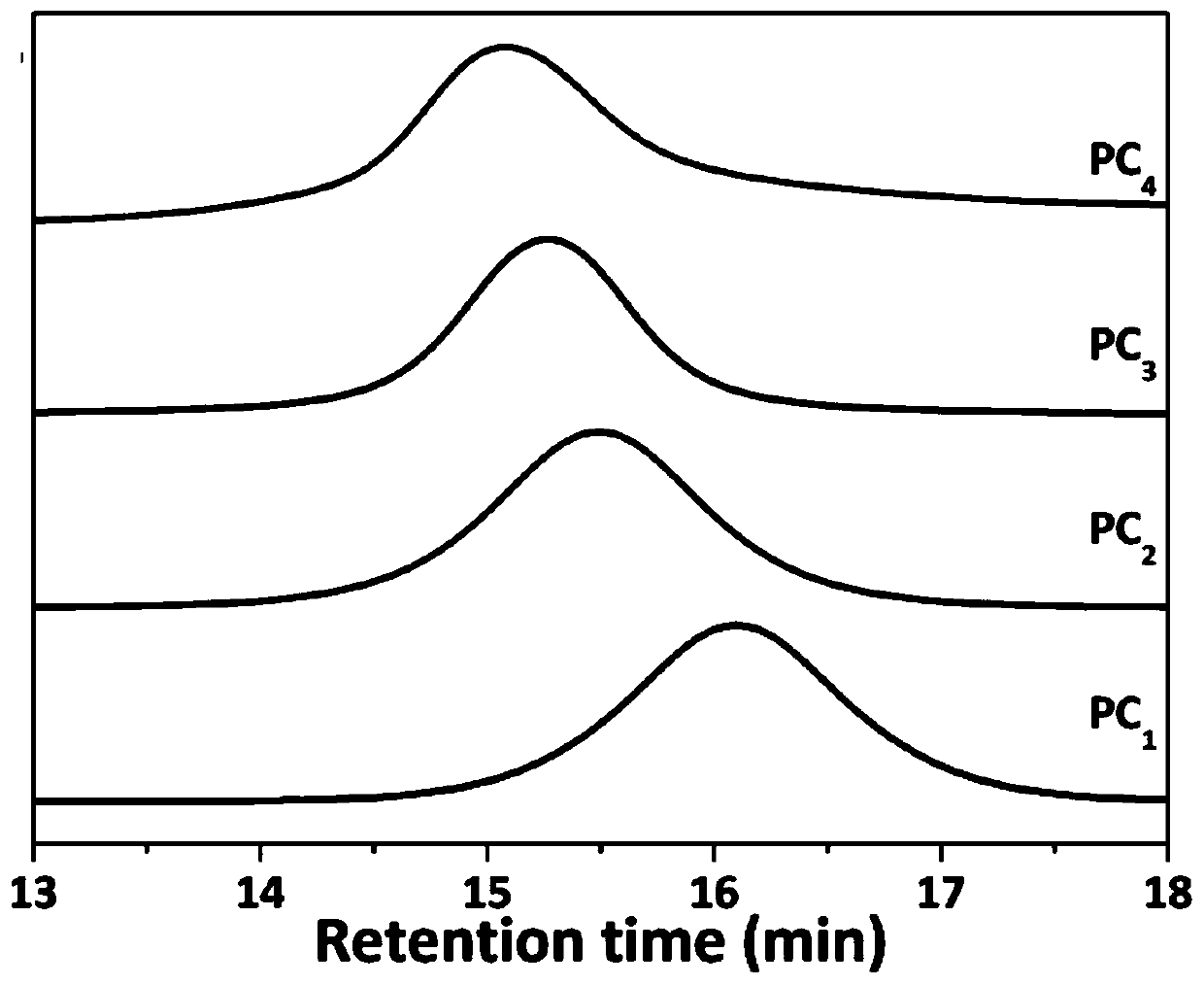

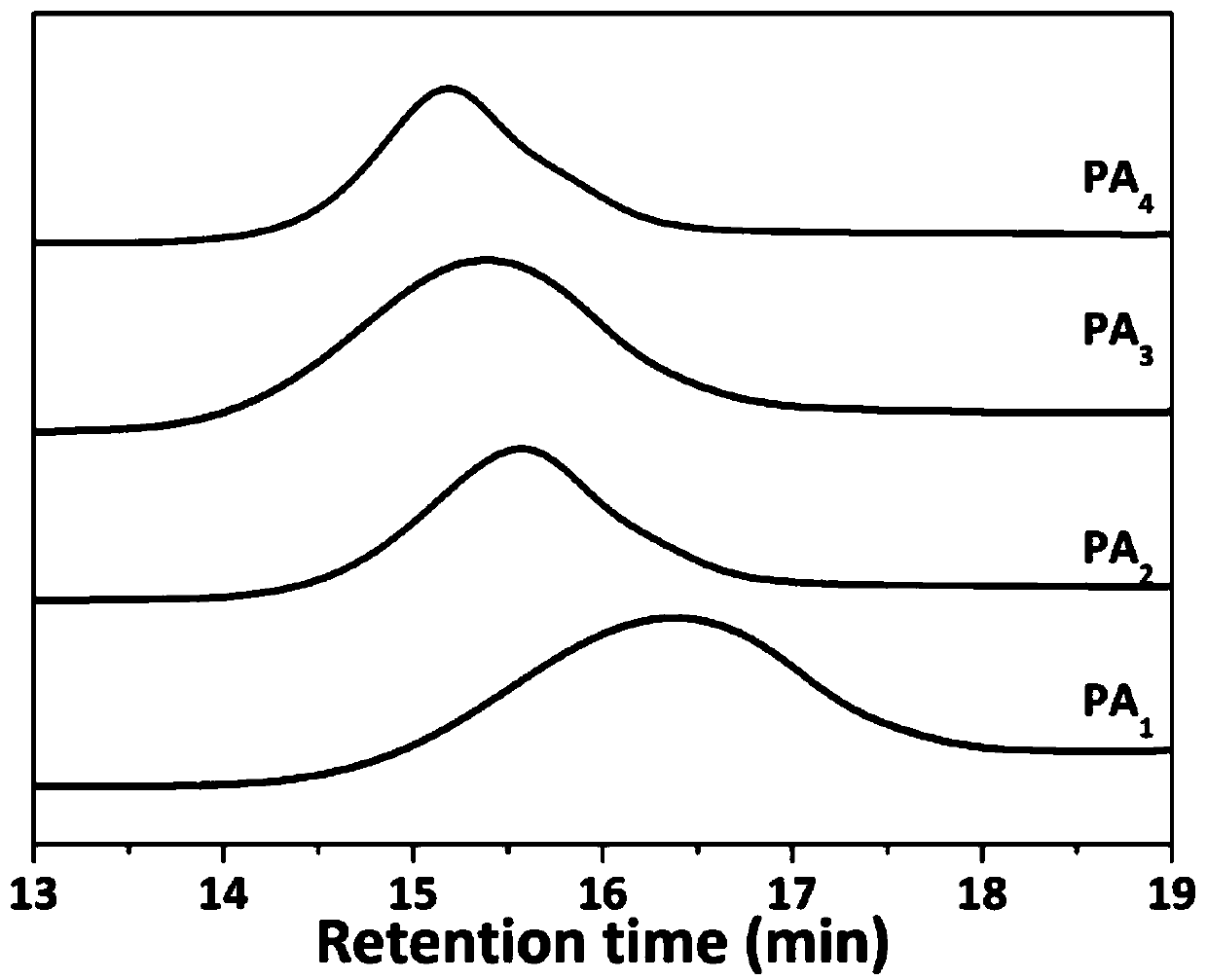

[0090] Take 2g of polyethylene glycol (Mn=4000Da, 0.5mmol) whose terminals are all hydroxyl groups, and 2.28g (2.2mL, 20mmol) ε-caprolactone into a 25mL round-bottomed flask, and then dropwise add 3‰ of Sn(Oct ) 2 and melted at 60°C, after deoxygenation by pumping Ar gas for three times, reacted at 140°C for 8h, and quenched at -20°C after the reaction was completed, and used 5mL of CH 2 Cl 2 Ultrasonic dissolution, the dissolved CH 2 Cl 2 The solution was added dropwise to 200 mL of glacial ether for sedimentation, and the white product was gradually precipitated. The mixture was suction-filtered with a sand core funnel and washed 3 times with anhydrous ether, and the resulting product was vacuum-dried to obtain a white solid powder PC 1 , the copolymer is ...

Embodiment 2

[0092] The embodiment of the present application provides a method for modifying a temperature-sensitive hydrogel material, and a modified temperature-sensitive hydrogel material, which includes the following steps:

[0093] Take 3g of polyethylene glycol (Mn=6000Da, 0.5mmol) and 2.28g (2.2mL, 20mmol) of ε-caprolactone, both of which are hydroxyl groups, and add them to a 25mL round-bottomed flask, and then add 3‰ of Sn(Oct ) 2 and melted at 60°C, after deoxygenation by pumping Ar gas for three times, reacted at 140°C for 8h, and quenched at -20°C after the reaction was completed, and used 5mL of CH 2 Cl 2 Ultrasonic dissolution, the dissolved CH 2 Cl 2 The solution was added dropwise to 200 mL of glacial ether for sedimentation, and the white product was gradually precipitated. The mixture was suction-filtered with a sand core funnel and washed 3 times with anhydrous ether, and the resulting product was vacuum-dried to obtain a white solid powder PC 2 , the copolymer is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com