Electronic blackboard frosted glass, electronic blackboard and frosted glass manufacturing method

A frosted glass and electronic blackboard technology, applied in the manufacture of electronic blackboards and frosted glass, and electronic blackboard frosted glass, can solve the problems of poor writing fluency and display clarity, and achieve improved writing fluency and high light transmittance. , the effect of smooth writing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

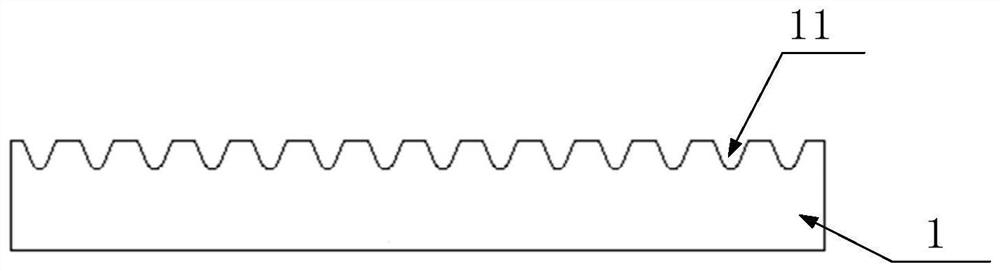

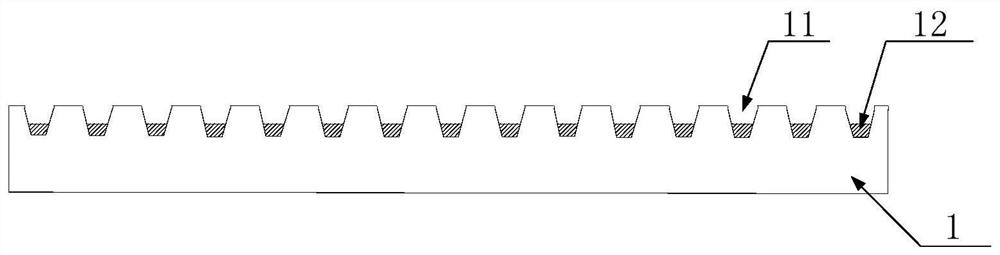

[0039] refer to figure 1 , the present embodiment provides a ground glass 1 for an electronic blackboard, wherein a plurality of grooves 11 are arranged on the front of the ground glass 1 of the electronic blackboard, and the plurality of grooves 11 are spaced apart from each other, and the ground glass 1 of the electronic blackboard The parts between two adjacent grooves 11 on the front are on the same plane, and the area occupied by the multiple grooves 11 on the front of the ground glass 1 of the electronic blackboard is less than or equal to 10% of the front area of the ground glass 1 of the electronic blackboard, for example but not It is limited that the area occupied by the plurality of grooves 11 on the front surface of the ground glass 1 of the electronic blackboard is 2% or 4% or 6% or 8% or 10% of the front area of the ground glass 1 of the electronic blackboard.

[0040] In this embodiment, a plurality of grooves 11 are provided on the front of the ground glass...

Embodiment 2

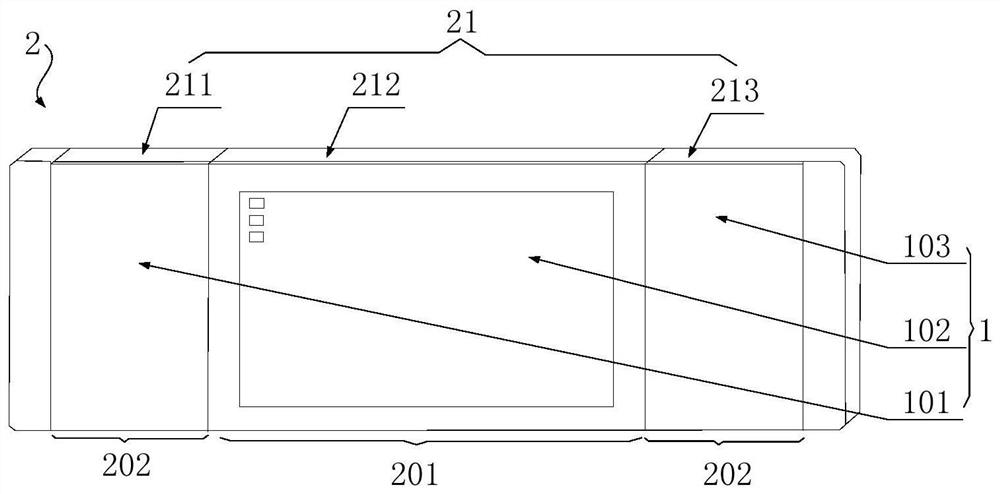

[0044] refer to image 3 , this embodiment provides an electronic blackboard 2 .

[0045] The electronic blackboard, also known as the smart blackboard, enables chalk or pen blackboard writing and multimedia playback to be realized on one blackboard, and blackboard writing can be written on the entire blackboard including the multimedia playback area, and blackboard writing and blackboard writing can be realized without improving the external structure of the electronic blackboard. The switching of the display mode is more convenient than the traditional single blackboard or projector, and the display effect is better. The electronic blackboard surface is equipped with electronic blackboard frosted glass with a certain roughness on the surface, which can realize the function of writing on the blackboard. At the same time, due to the transparent characteristics of the electronic blackboard frosted glass, a liquid crystal module and a touch film are arranged between the electron...

Embodiment 3

[0051] This embodiment provides a frosted glass manufacturing method for manufacturing electronic blackboard frosted glass, refer to Figure 4 , Figure 5 and Figure 7 , the frosted glass manufacturing method comprises a mask covering step S1, a hydrofluoric acid etching step S2, and a tempering step S3; wherein, the mask covering step S1 refers to covering the front surface of the flat glass 4 with a plurality of open holes acid-resistant Mask 5; hydrofluoric acid etching step S2 refers to using hydrofluoric acid to etch the front of the straight glass 4 covered with acid-resistant mask 5, so as to corrode a plurality of grooves 11 on the front of the straight glass 4, more The area of the front of the flat glass 4 occupied by each groove 11 is less than or equal to 10% of the front area of the straight glass 4, such as but not limited to, the area of the front of the flat glass 4 occupied by a plurality of grooves 11 is equal to or less than 10% of the front area of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com