Non-aqueous electrolyte additive, non-aqueous electrolyte and lithium-ion battery

A non-aqueous electrolyte and lithium-ion battery technology, applied in secondary batteries, secondary battery repair/maintenance, circuits, etc., can solve problems such as large battery impedance, decreased electrochemical performance, and SEI film damage, and achieve high The effect of stable voltage performance and film formation structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

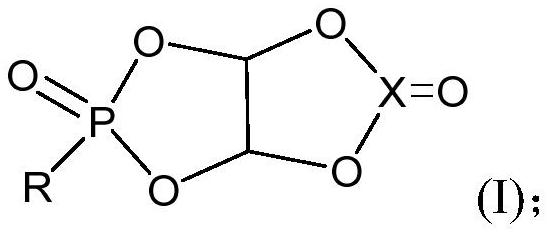

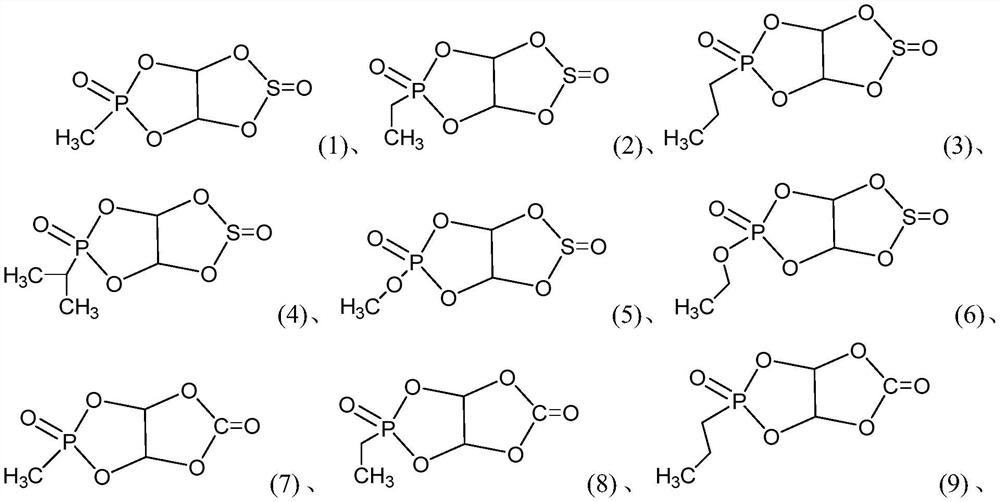

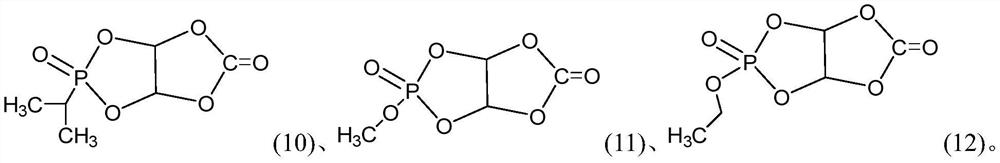

[0049] According to some embodiments provided by the present invention, the compound of formula (I) is a compound having one of the following structures:

[0050]

[0051] The above-mentioned compound of formula (I) can oxidize and polymerize to form a film on the surface of the NCM positive electrode material, react with the hydroxyl groups on the surface of the SiC negative electrode material, and undergo reductive polymerization and crosslinking to form an SEI film with certain mechanical strength and toughness on the surface of the silicon carbon negative electrode. Thereby improving the high-voltage performance of NCM-SiC lithium-ion batteries.

[0052] According to some embodiments provided by the present invention, the amount of the compound of formula (I) added is 0.1% to 2.0%, such as 0.1%, 0.2%, 0.3%, based on the sum of the mass of the solvent and the electrolyte lithium salt as 100%. , 0.4%, 0.5%, 0.6%, 0.7%, 0.8%, 0.9%, 1.0%, 1.1%, 1.2%, 1.3%, 1.4%, 1.5%, 1.6%,...

Embodiment 1

[0091] In this embodiment, the provided electrolyte includes fluoroethylene carbonate (FEC), ethylene carbonate (EC), ethyl methyl carbonate (EMC), diethyl carbonate (DEC) mixed solvent, and the lithium salt is LiPF 6 , additive compound (12).

[0092] The preparation method of the electrolyte is: in a glove box with a moisture content of less than 10ppm, mix the solvent evenly according to the mass fraction EC:FEC:EMC:DEC=2:1:4:3, dry to remove water and impurities, and add refined Electrolyte lithium salt LiPF 6 Prepare a solution with a lithium salt concentration of 1.2 mol / L, fully stir and mix evenly, then add 1.0% of compound (12) based on the sum of the mass of the solvent and lithium salt as 100%, and fully stir and mix uniformly to obtain an electrolytic solution liquid.

Embodiment 2

[0094] The difference from Example 1 is that the sum of the mass of solvent and lithium salt is 100%, and the addition amount of compound (12) is 0.5%; the rest are the same as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com