Industrial waste gas desulfurization dust removal device

A technology for desulfurization and dust removal, industrial waste gas, applied in gas treatment, use of liquid separation agent, membrane technology, etc., can solve problems such as damage to treatment equipment and inadequate waste gas desulfurization treatment, and achieve the effect of improving the degree of integration and adequacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

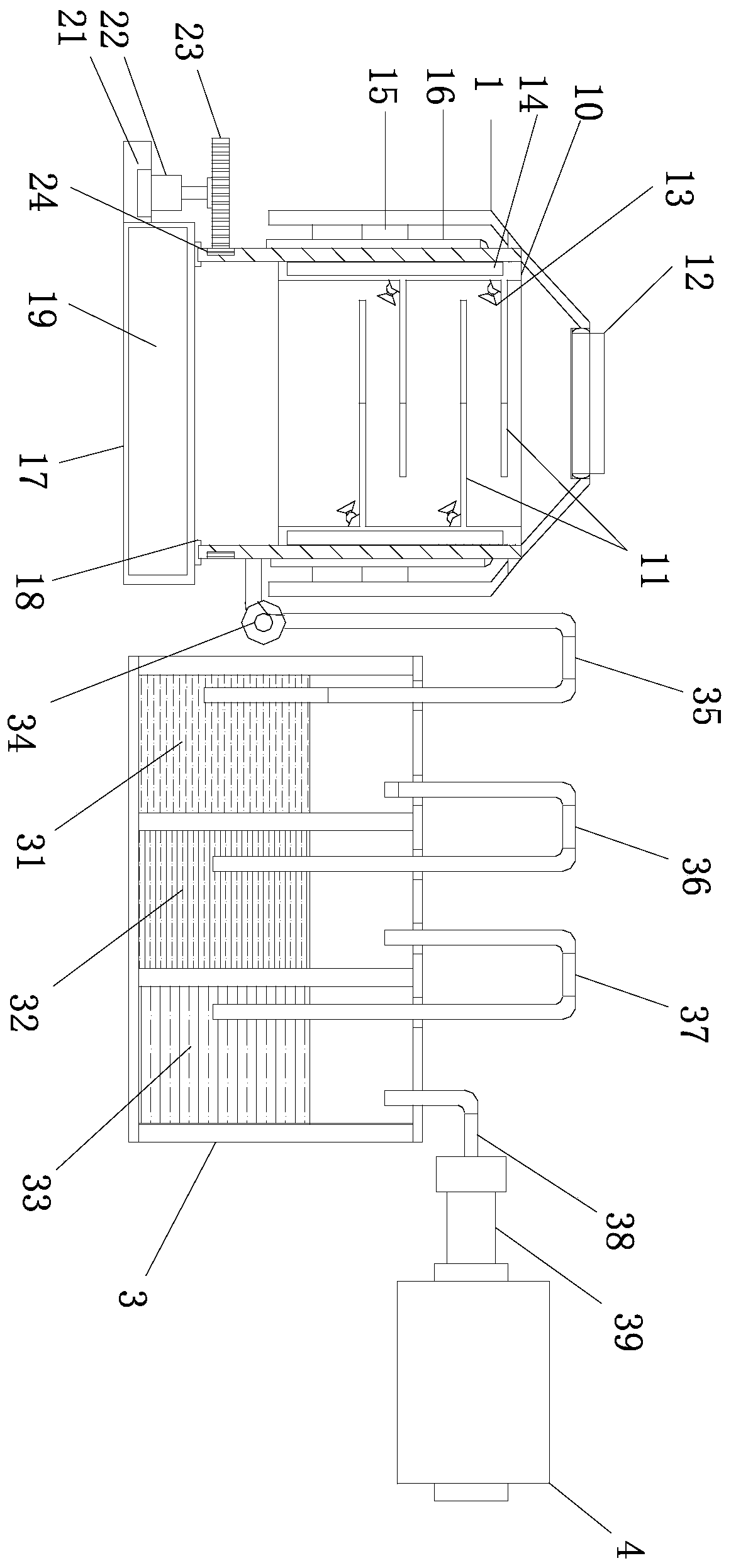

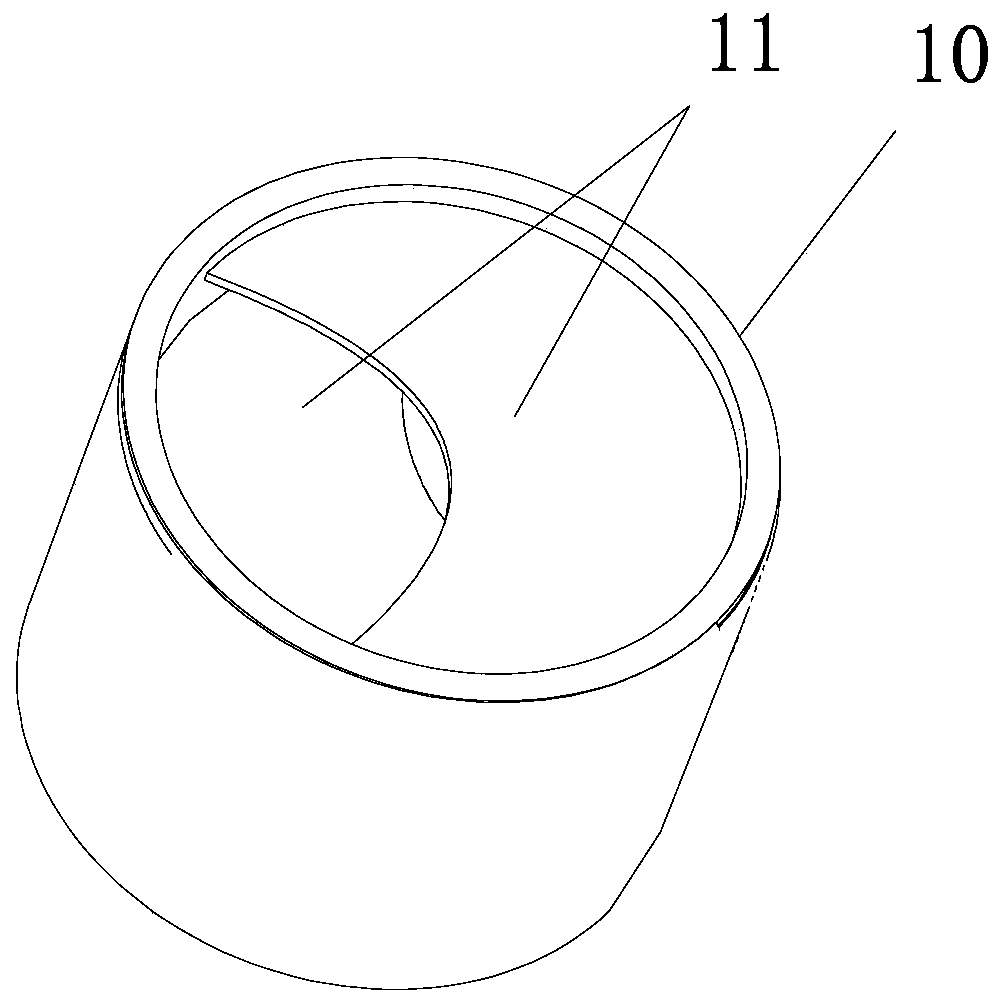

[0030] see figure 1 and figure 2 , an industrial waste gas desulfurization and dust removal device, comprising a primary purification box 1 and a secondary purification box 3, the top of the primary purification box 1 is provided with an air inlet 12, and the inner cavity of the primary purification box 1 is provided with Cooling tube 10, the cooling tube 10 is arranged at the air inlet end of the air inlet 12, the inner cavity of the cooling tube 10 is provided with several barrier plates 11, between the barrier plates 11 and the inner wall of the cooling tube 10 are An arc-shaped gap is designed, and the adjacent group of partitions 11 are arranged in a staggered shape. A shower head 13 is installed at the angle between the fixed end of the partition board 11 and the inner wall of the cooling tube 10. The outer wall of the cooling tube 10 is provided with a water storage cavity 14, and the water storage cavity 14 is connected with the shower head 13 through a conduit.

[...

Embodiment 2

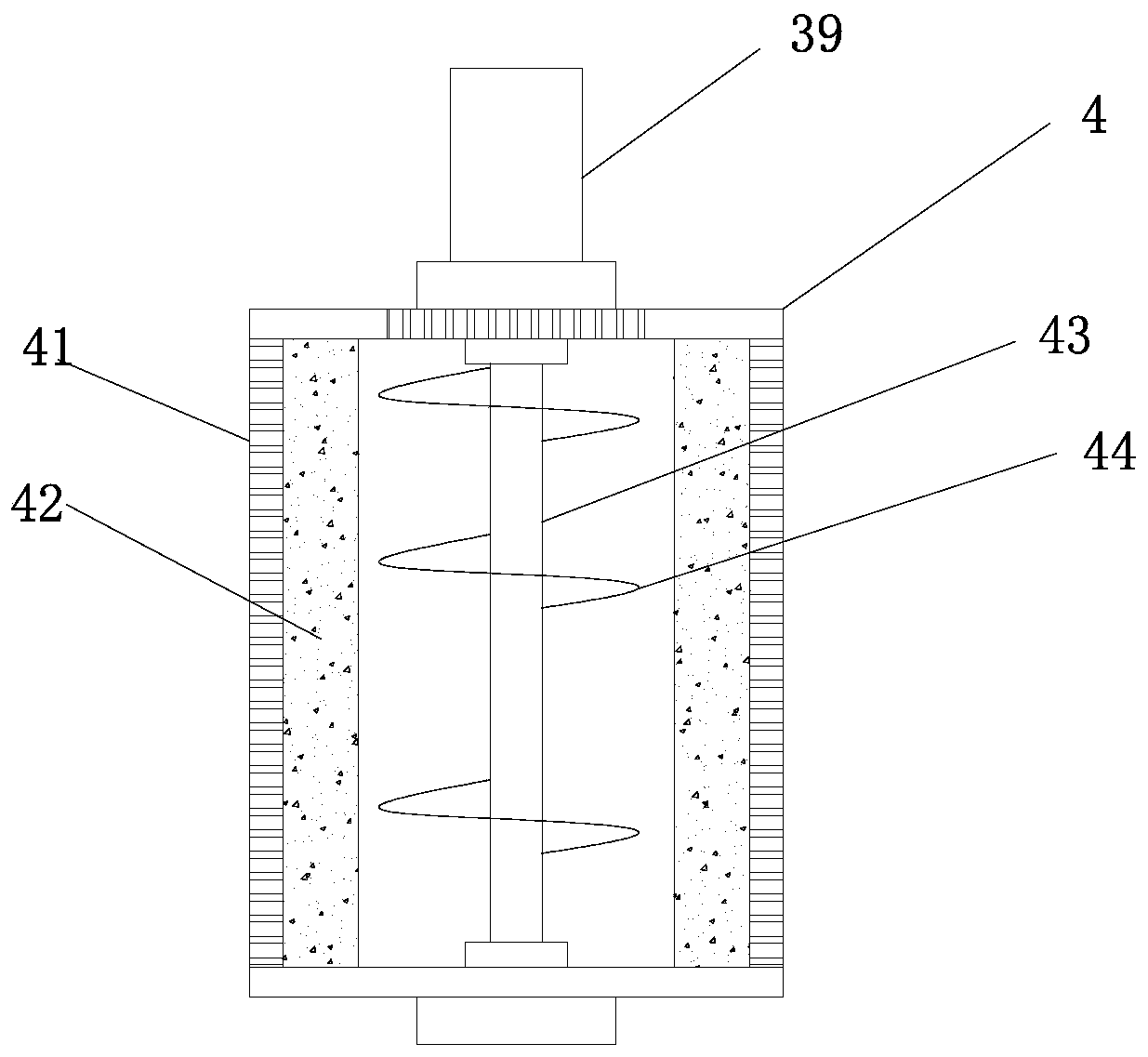

[0038] see image 3 , this embodiment is further optimized as Embodiment 1. On the basis of it, an exhaust pipe 38 is installed on the top of the lipid absorption chamber 33, and the exhaust pipe 38 is externally connected to a booster pump 39, and the booster pump The air delivery end of 39 is externally connected with an exhaust tube 4, the side wall of the exhaust tube 4 is provided with an exhaust mesh 41, and the inner wall area of the exhaust tube 4 is provided with an adsorption layer 42. The inner cavity of 4 is equipped with a centerline rotating shaft 43, and a curved fan blade 44 is installed on the centerline rotating shaft 43.

[0039] Although ethanol is a non-polluting substance, in view of the high concentration of ethanol at the discharge end of the exhaust pipe 38, there is a risk of being ignited by an open flame. This application is equipped with a booster pump 39 at the exhaust to push the airflow through the adsorption layer 42 and then discharge it. ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com