Beneficiation method for airflow classification of garnet ore with uneven disseminated grain size

A beneficiation method, garnet technology, applied in the direction of solid separation, etc., can solve the problems of uneven distribution of garnet coarse and fine particles, poor sorting effect, poor beneficiation index, etc., to improve the overall recovery rate, reduce interference, and effectively recover Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The main component mineral of a garnet ore in Shanxi is garnet, with a garnet content of 35%, followed by quartz, and a small amount of pyroxene, amphibole, feldspar, mica, trace rutile and others.

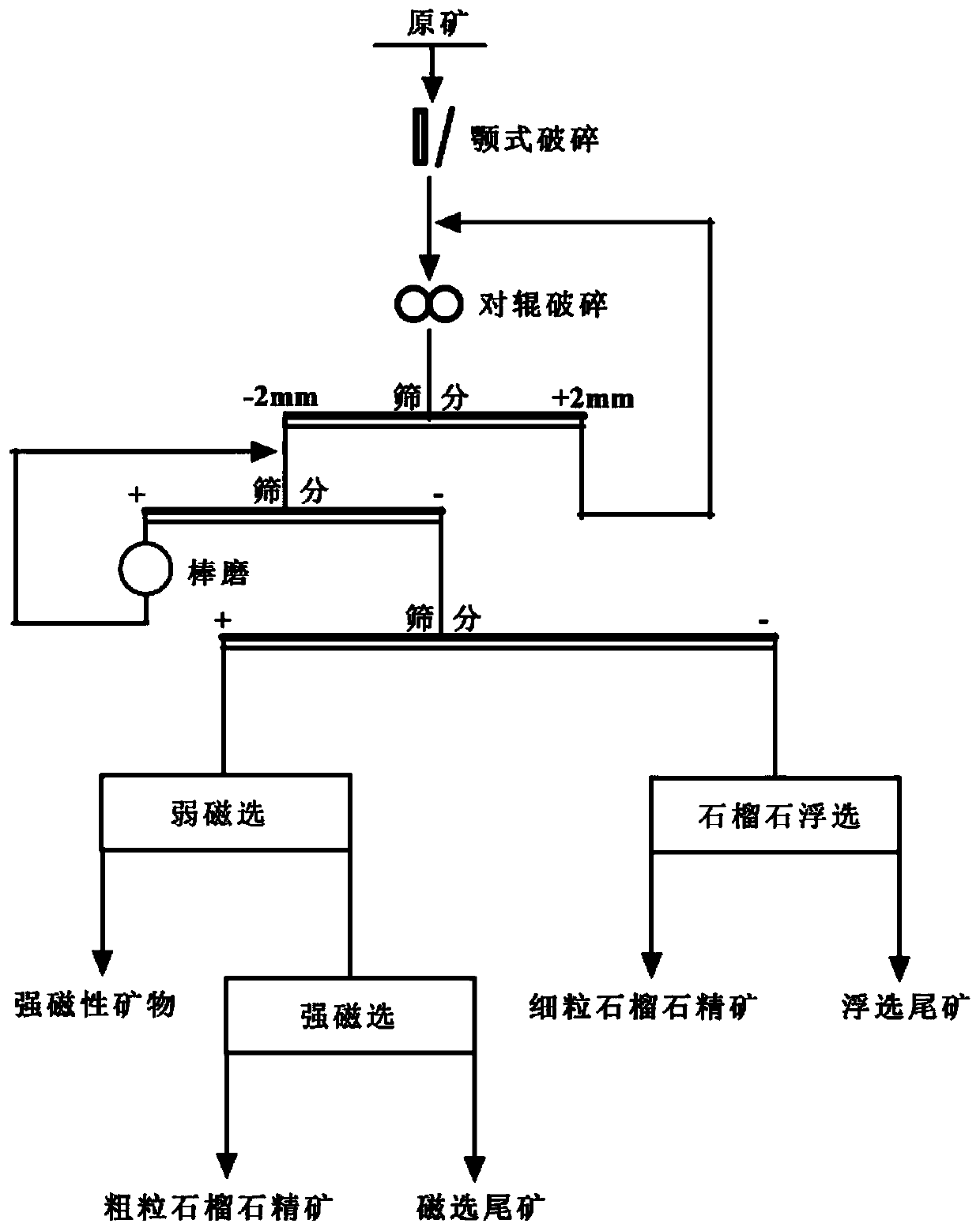

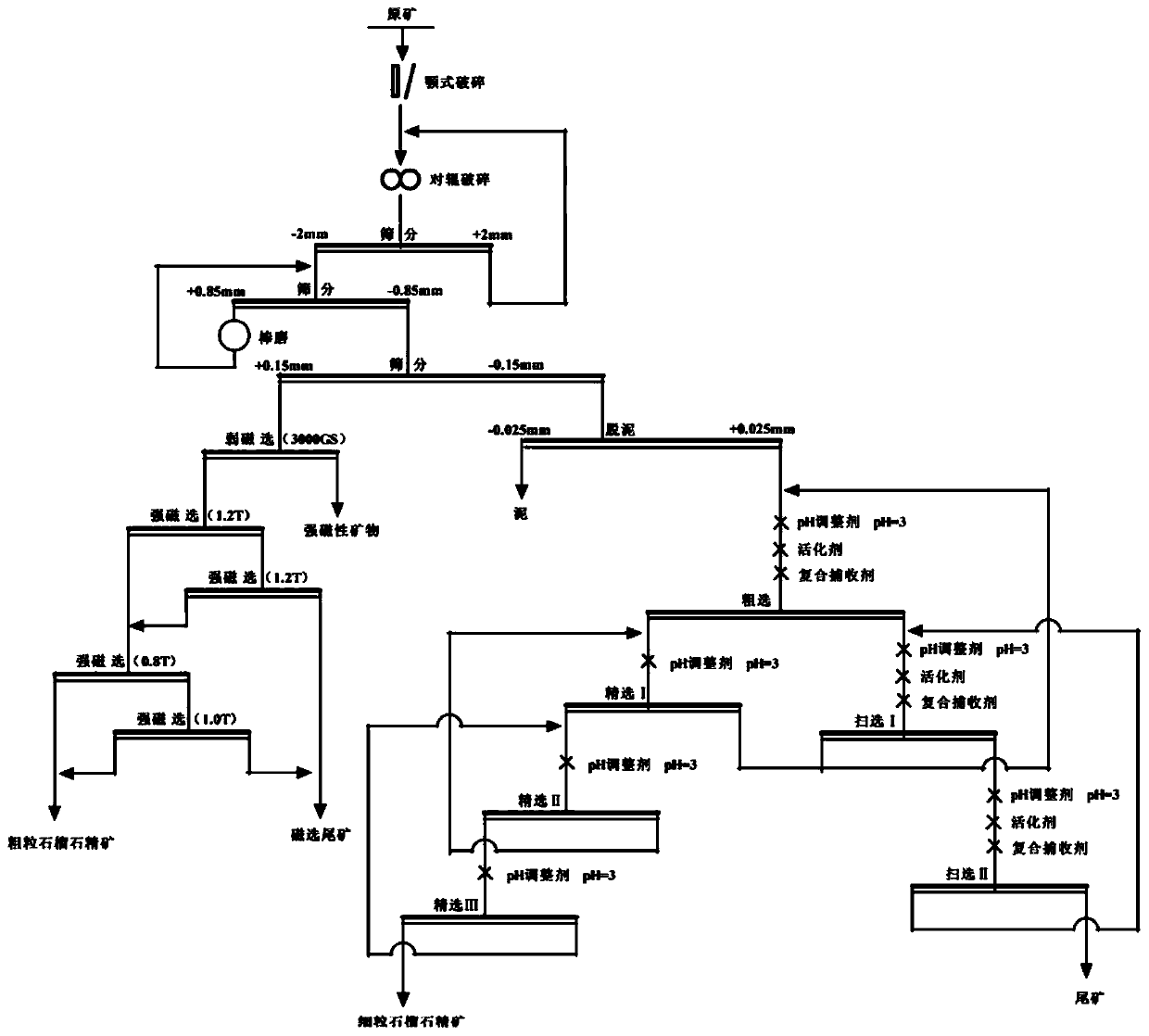

[0035] Such as figure 1 with figure 2 As shown, a beneficiation method for split separation of garnet ore with uneven distribution particle size is used for beneficiation of the above-mentioned garnet ore in Shanxi, which may specifically include the following steps:

[0036] Step 1. The steps of raw ore crushing: take the above-mentioned garnet ore in Shanxi as raw ore, first use a crusher to jaw crush the raw ore, and then perform roller crushing until the particle size is not greater than 2mm, and then pass the 0.85mm standard Sieve, the ore with a particle size greater than 0.85mm is subjected to closed-circuit grinding with a rod mill, that is, the ore with a particle size greater than 0.85mm is ground through the rod mill, and the ground ore after grinding is passed throug...

Embodiment 2

[0044] A garnet mine in Lianyungang, Jiangsu Province is mainly composed of garnet and pyroxene, with a garnet content of 52.93%, followed by actinolite, amphibole, etc., and a small amount of rutile, chlorite, serpentine, albite, etc. .

[0045] Such as figure 1 with figure 2 As shown, a beneficiation method for split separation of garnet ore with uneven distribution particle size is used for beneficiation of a garnet ore in Lianyungang, Jiangsu. The specific steps are the same as in Example 1 of the present invention, and the difference lies in the above A garnet mine in Lianyungang, Jiangsu is used as a raw ore.

[0046] Specifically, after analysis and testing, the final beneficiation technical indicators of Example 2 of the present invention are shown in Table 2 below:

[0047] Table 2

[0048] product name Garnet content,% Mineral recovery rate,% Coarse garnet concentrate93.4345.34 Fine-grained garnet concentrate 91.5237.12

[0049] In summary, the embodiments of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com