Laser cleaning device and method adopting inert gas for auxiliary cleaning

A technology of inert gas and laser cleaning, which is applied in the direction of cleaning methods and appliances, laser welding equipment, chemical instruments and methods, etc., can solve the problems of secondary damage to samples, high temperature field, etc., to improve quality, isolate operators and The effect of reaction space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

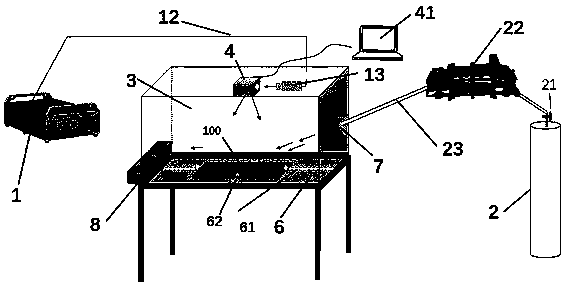

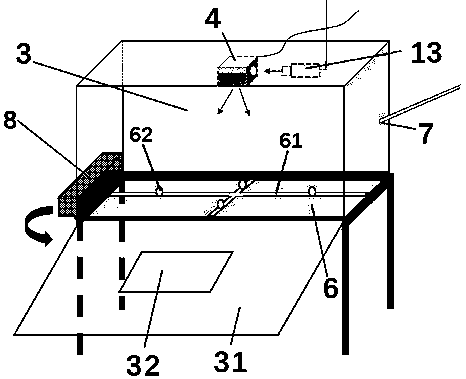

Method used

Image

Examples

Embodiment 1

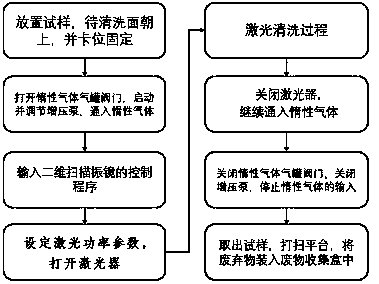

[0026] Optionally attached with a thickness of 1mmAl 2 o 3 The double-layer material of 2024 aluminum alloy with an oxide layer of 5cm×5cm×1cm is the sample 100 to be cleaned. Argon gas (ie inert gas) is used, and a layer of high-temperature-resistant glass fiber is placed outside the waste collection box. Al 2 o 3 The oxide layer is cleaned.

[0027] The first step: first place the sample 100 to be cleaned on the center of the platform 6, and place the Al 2 o 3 The cleaning surface is facing upwards, and the four sides of the sample 100 to be cleaned are fastened by clamps 62 for fixing.

[0028] Step 2: Open the valve 21 at the outlet of the inert gas tank 2, start the booster pump 22, set the output pressure to about 15MPa, and make the inert gas output continuously for 5mins. At the same time, observe whether the sample 100 to be cleaned is loose. Adjust the holding state of the sample to be cleaned until the sample to be cleaned is stable and firm under the impact o...

Embodiment 2

[0035] Select a 7075 aluminum alloy substrate of 10cm×10cm×2cm, and apply a 100μm acrylic polyurethane paint layer on the upper layer, use argon gas (that is, inert gas), and cover the outside of the waste collection box with a layer of high-temperature-resistant glass fiber. Clean the acrylic polyurethane paint layer of the object to be cleaned.

[0036] Among them: the third step is to set the laser output power of the laser host 1 as 500W, input and control the laser scanning parameters in the computer 41, the spot diameter is 0.5mm, the scanning speed is 2500mm / s, and the spot overlap rate is 50%. In the fourth step, the cleaning time is 16s. Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com