Laser drilling device

A technology of laser drilling and placing boards, which is applied in the direction of auxiliary devices, laser welding equipment, auxiliary welding equipment, etc., can solve the problems of lack of material positioning, material displacement caused by force, and reduce the practicality of laser drilling devices, etc., to achieve Ease of positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to further understand the content, features and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings.

[0032] The structure of the present invention will be described in detail below in conjunction with the accompanying drawings.

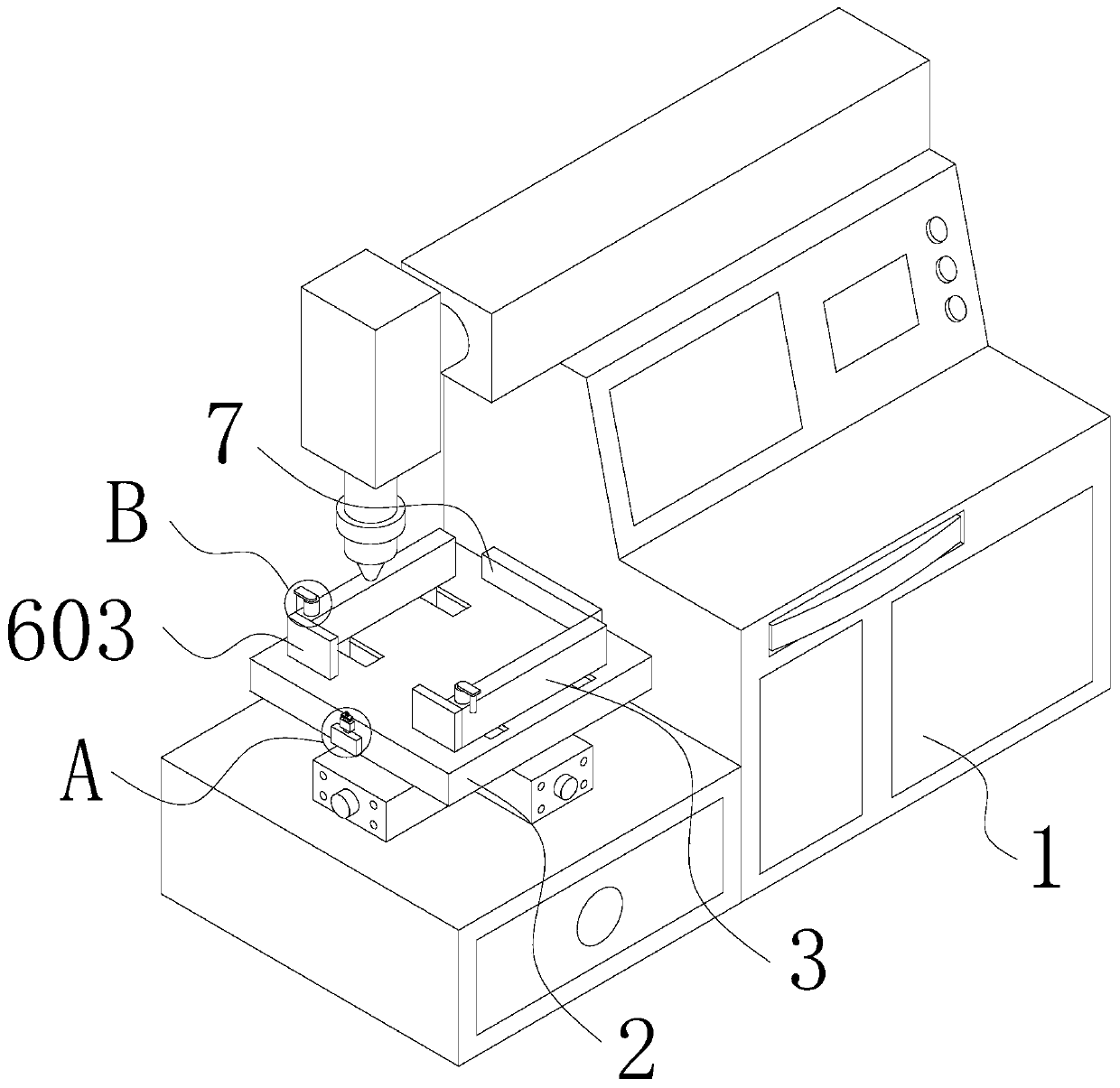

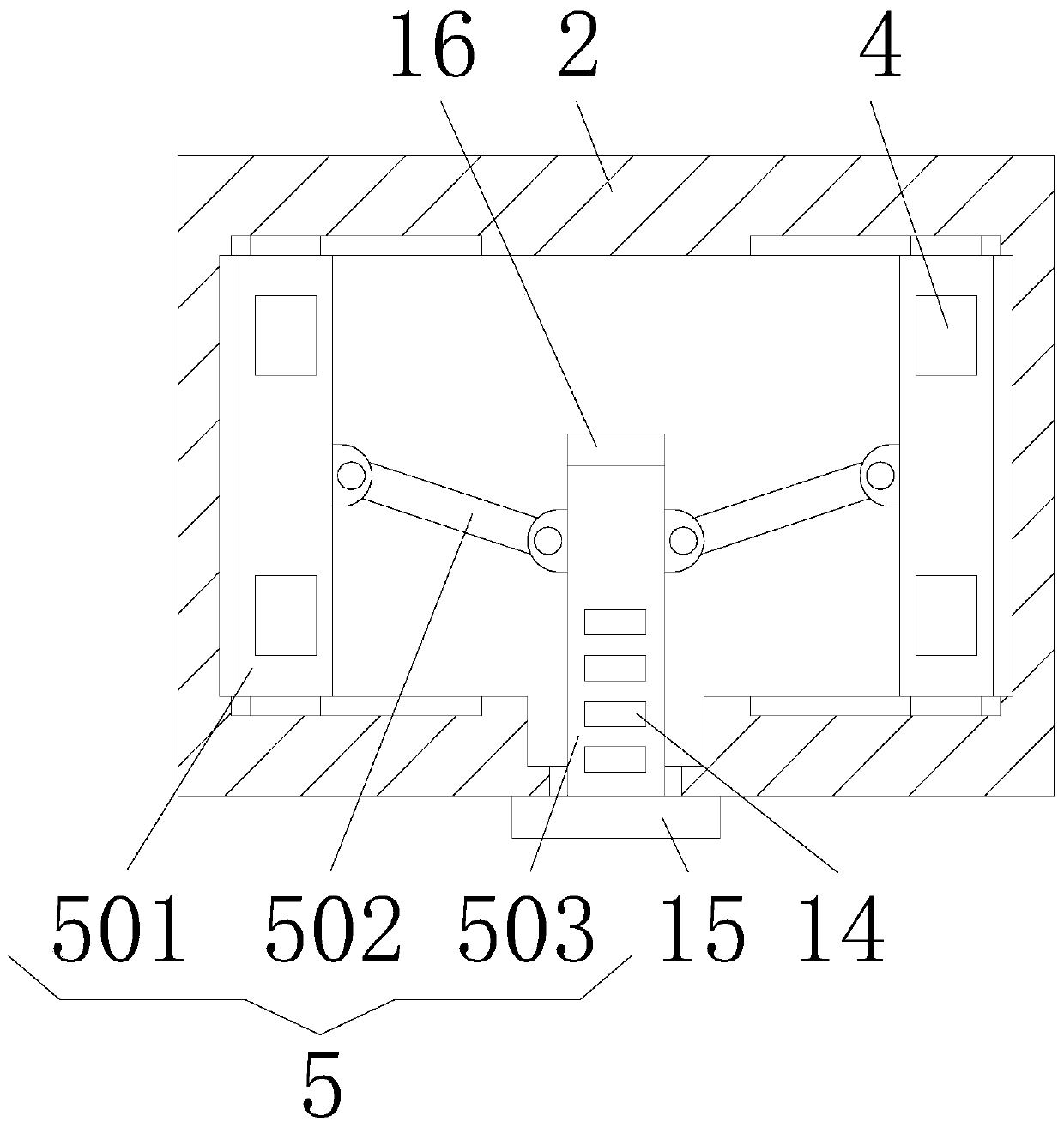

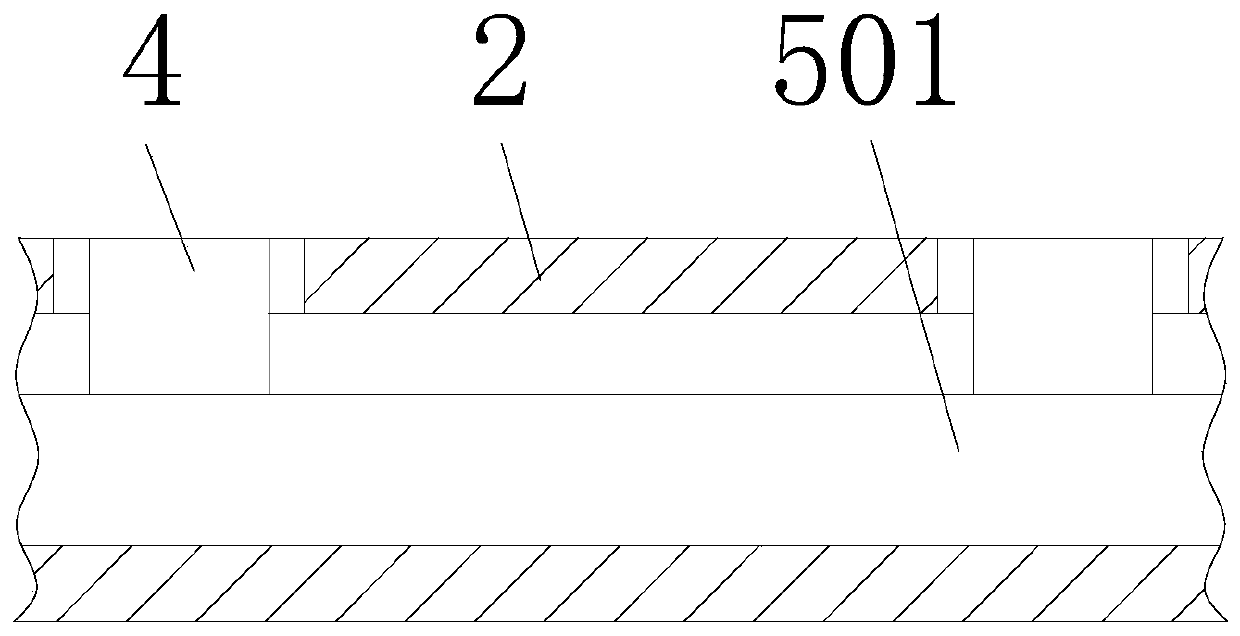

[0033] Such as Figure 1 to Figure 8 As shown, a laser drilling device provided by the embodiment of the present invention includes a punching machine 1, the top of the punching machine 1 is fixedly connected with a placement plate 2, and both sides of the top of the placement plate 2 are movably connected with a positioning plate 3, The front side and the rear side of the bottom of the positioning plate 3 are fixedly connected with the connecting rod 4, the inner cavity of the placing plate 2 is movably connected with the transmission mechanism 5, the bottom of the connecting rod 4 is fixedly connected with the transmission mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com