Production process of carbonized wood wallboards for antique buildings

A technology of production technology and antique architecture, which is applied in wood processing equipment, manufacturing tools, charcoal burning/combustion, etc. It can solve the problems of wood carbonization, deformation and cracking, and easy expansion, etc., so as to achieve not easy deformation and cracking, and moisture content balance , the effect of not easy to crack and deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

[0048] Embodiment 1-5 all relates to a kind of production technology of the carbonized wood wall panel that antique building is used, specifically comprises the following steps:

[0049] (1) Pretreatment

[0050] Carry out preliminary processing on the fir wallboard, choose one side as the bottom surface, and first scrape and plan the bottom surface to be straight and smooth, (the processed surface must not be distorted). After the bottom surface is scraped and planed, the sides are processed. The dimensions are 85*1005*35mm rectangular wallboard blanks.

[0051] (2) Typesetting

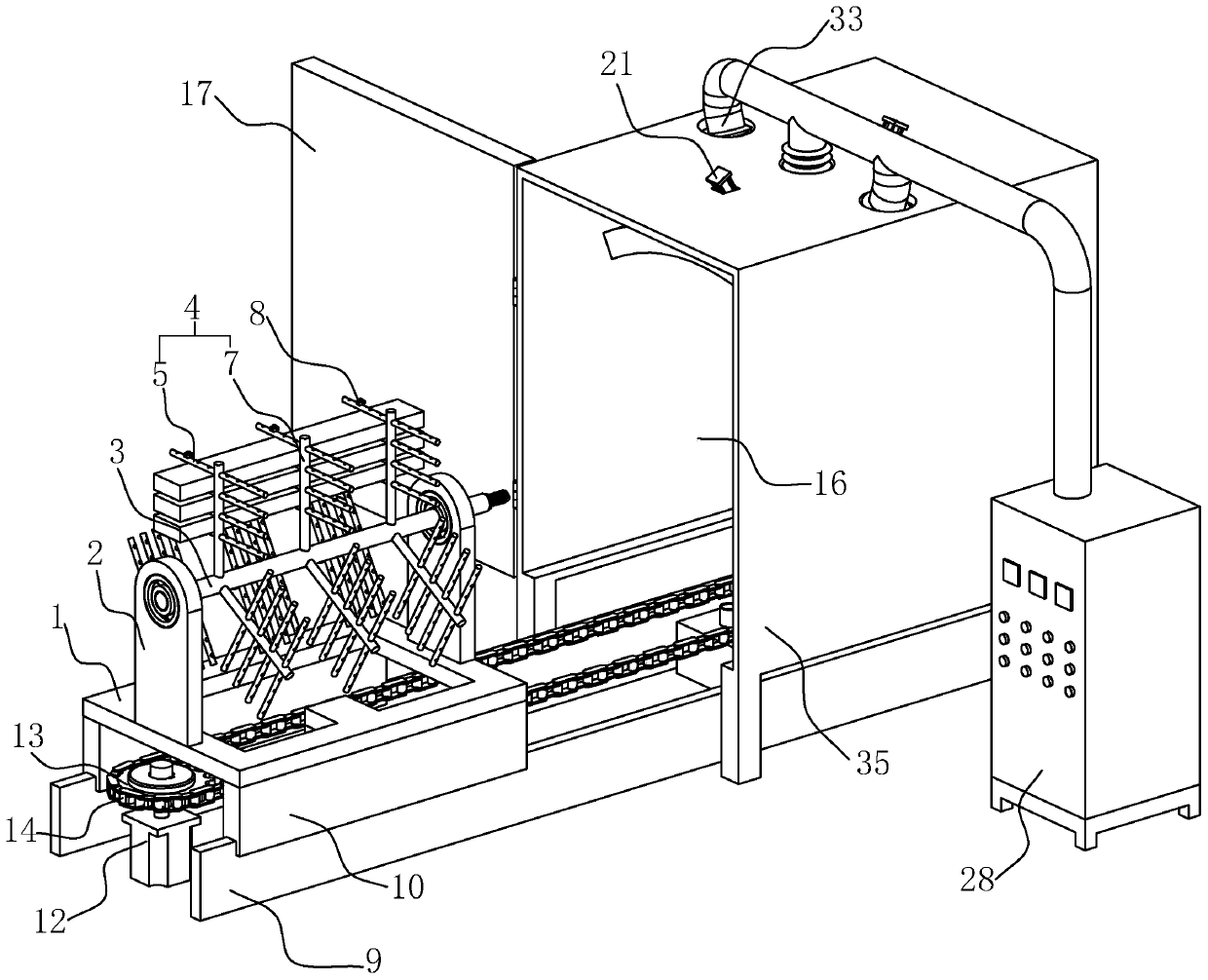

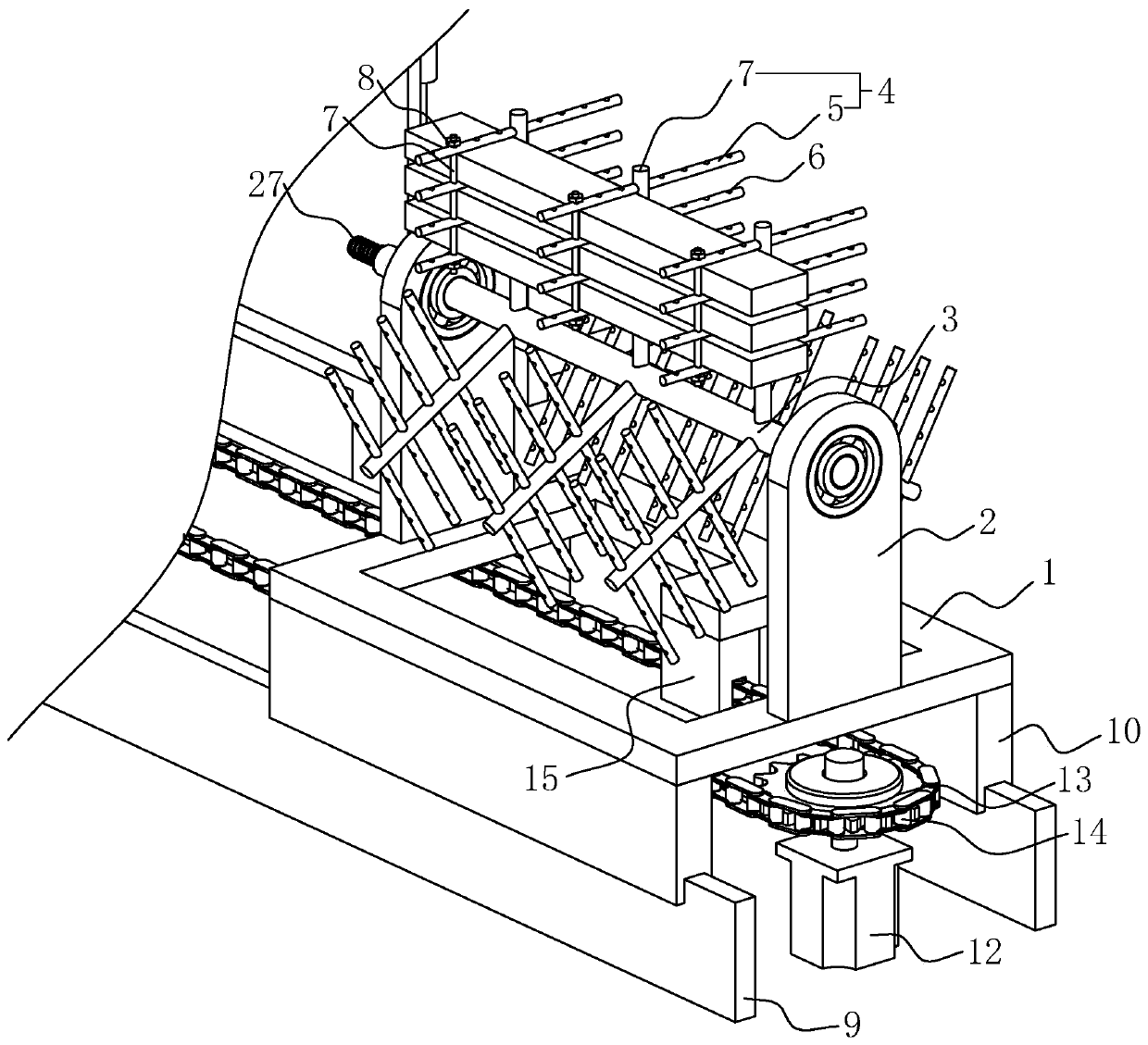

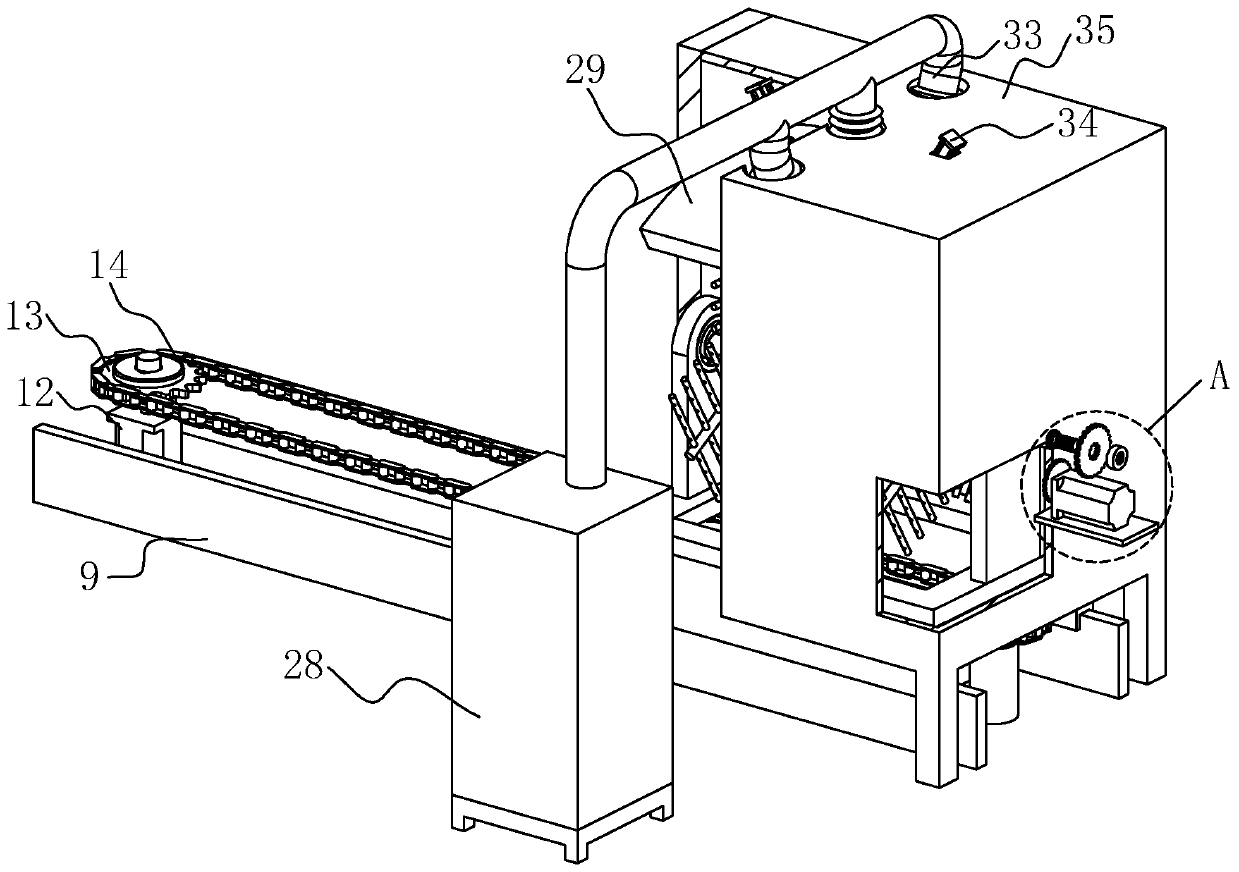

[0052] Stack the made wallboard blanks on the blank stacking rack, refer to figure 1 and figure 2 , the used billet stacking frame includes a rectangular frame base 1 and a support frame 2 vertically arranged at both ends of the base 1 in the length direction, a rotating shaft 3 is arranged between the two supporting frames 2, and both ends of the rotating shaft 3 run through the supporting fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com