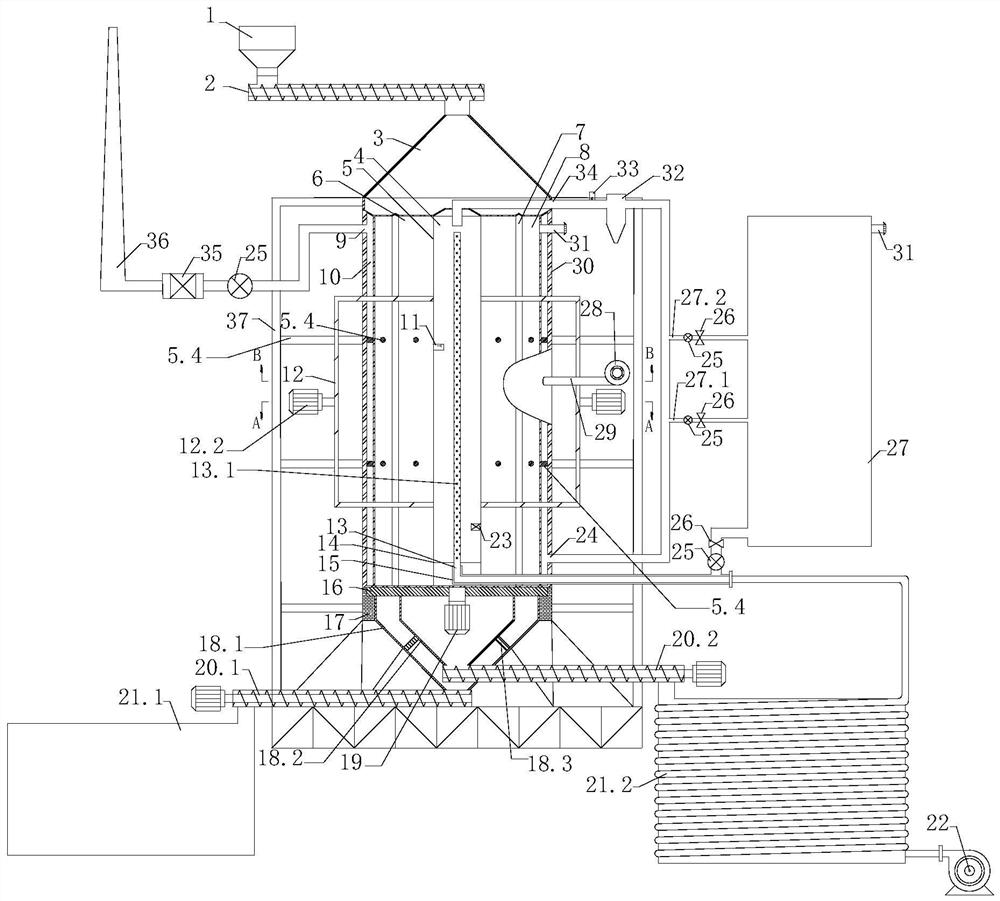

Continuous biomass carbonization device and method for gas-solid classification pyrolysis differential classification

A technology of graded pyrolysis and biomass charcoal, which is used in biofuels, special forms of dry distillation, coke ovens, etc., can solve the problems of incomplete carbonization of internal biomass particles, excessive carbonization of surface biomass, and small heating area of the furnace. Accelerate the carbonization rate, achieve good carbonization effect, and avoid the effect of incomplete carbonization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

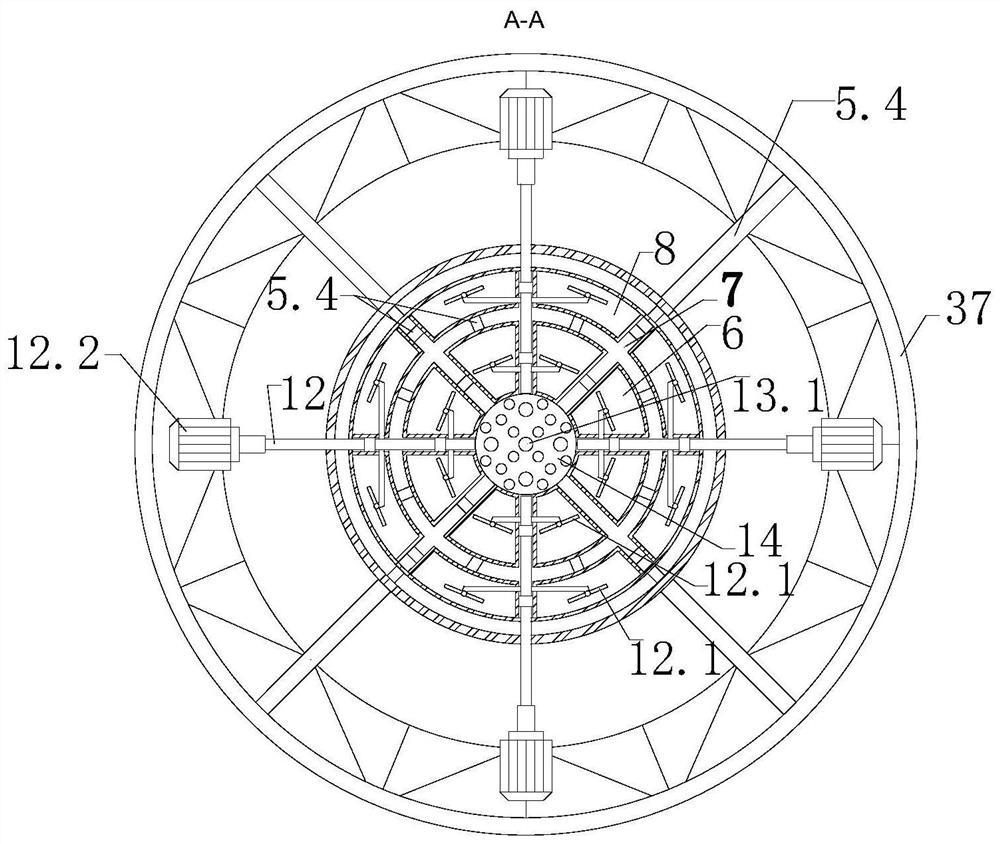

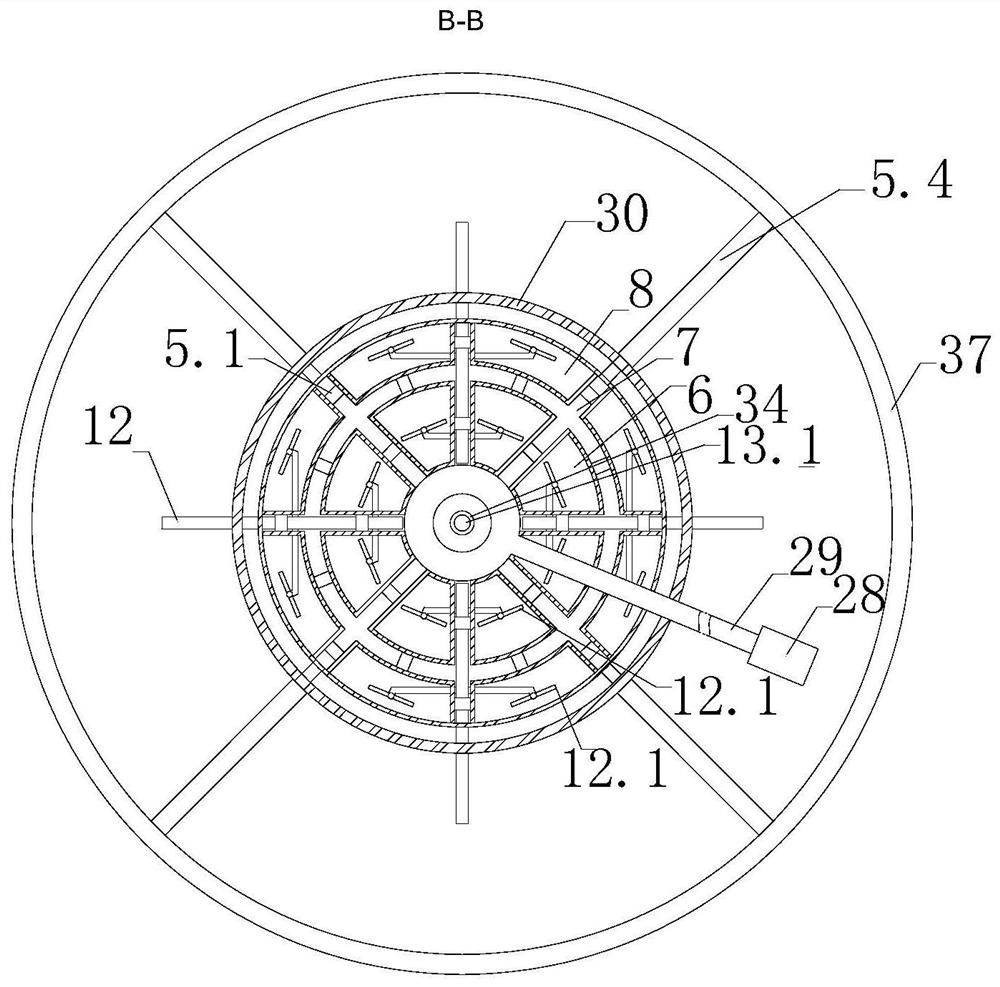

Method used

Image

Examples

Embodiment example 1

[0063] The raw material is straw, and the natural bulk density is 80kg / m 3 , the fast charcoal pyrolysis furnace can accommodate 223.2kg of straw, and the carbonization cycle is 4h, and the slow charcoal pyrolysis furnace can accommodate 237.6kg of straw, and the carbonization cycle is 5h. The speed of the feed auger is 80-85r / min, the speed of the slow carbon discharge auger conveyor is 10-15r / min, the speed of the fast carbon discharge auger conveyor is 13-18r / min, and the carbonization can be 2479.7 in 24 hours kg of straw, the carbon production rate of the fast charcoal thermal junction furnace is about 30%, and the charcoal yield of the slow charcoal pyrolysis furnace is about 35%. Part of the total heat of straw is used for combustion in the form of pyrolysis gas to provide carbonization heat, which is insufficient The energy is provided by external gas, which can realize continuous carbonization and discharging automation. The carbon production rate of fast carbon is ab...

Embodiment example 2

[0065] The raw material is chaff, the natural bulk density is 160kg / m 3 , the fast charcoal pyrolysis furnace can accommodate 446.4kg of chaff, the carbonization cycle is 4h, the slow charcoal pyrolysis furnace can accommodate 475.2kg of chaff, the carbonization cycle is 5h, the feeding auger speed is 40~45r / min, the slow speed The speed of the charcoal discharge auger conveyor is 13-18r / min, and the speed of the fast charcoal discharge auger conveyor is 15-20r / min. It can carbonize 4959kg of chaff after 24 hours of stable operation. The charcoal production rate of the fast charcoal pyrolysis furnace is about 35%, the charcoal production rate of the slow charcoal pyrolysis furnace is about 40%, part of the total heat energy of chaff is used for combustion in the form of pyrolysis gas to provide heat, and the insufficient energy is provided by gas, which can realize continuous charcoalization and automatic discharge , the charcoal production rate of fast charcoal is about 39kg / ...

Embodiment example 3

[0067] The raw material is biomass pellets with a natural bulk density of 300kg / m 3, The fast charcoal pyrolysis furnace can accommodate 837kg, the carbonization cycle is 4h, the slow charcoal pyrolysis furnace can accommodate 891kg, and the carbonization cycle is 5h. The speed of the feed auger is 40-45r / min, the speed of the slow carbon discharge auger conveyor is 25-30r / min, and the speed of the fast carbon discharge auger conveyor is 28-33r / min, which can carbonize 9299kg raw material in 24 hours. For material particles, the carbon production rate of the fast charcoal pyrolysis furnace is about 33%, and the charcoal production rate of the slow charcoal pyrolysis furnace is about 37%. Part of the total heat of biomass pellets is used for combustion to provide heat in the form of pyrolysis gas Other energy is provided by gas, which can realize continuous carbonization and discharging automation. The carbon production rate of fast carbon is about 69kg / h, the daily carbon prod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com