Tower-mounted wrapping tape dragging-wrapping machine with self-adaptive tension adjustment

A tension-adjusting and self-adapting technology, applied in the directions of transportation and packaging, winding strips, electrical components, etc., can solve the problems of limited tape length, poor cable tape layer consistency, frequent tape replacement, etc., to reduce replacement The frequency of wrapping tape, the effect of improving work efficiency and length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The invention proposes a tower-mounted strapping and towing machine with self-adaptive tension adjustment.

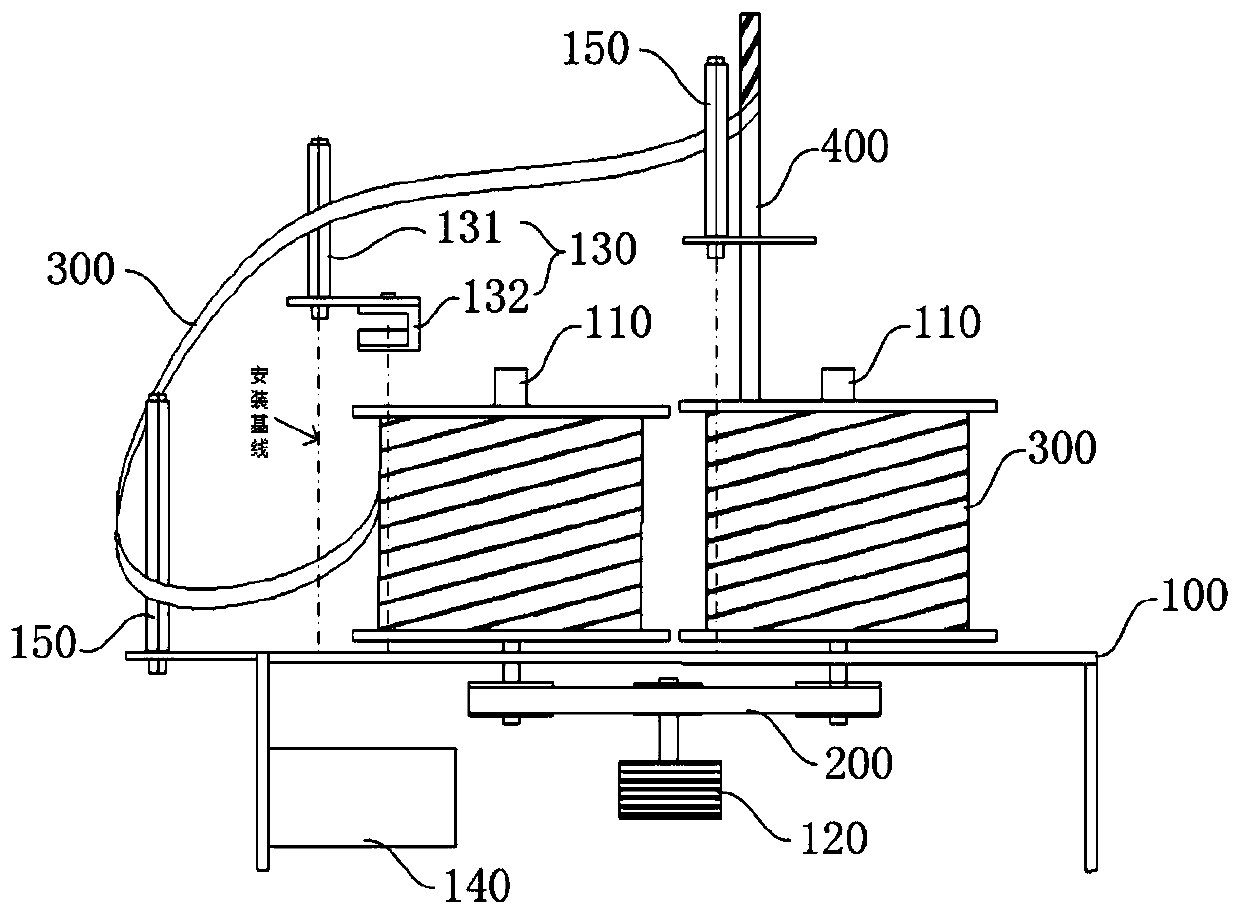

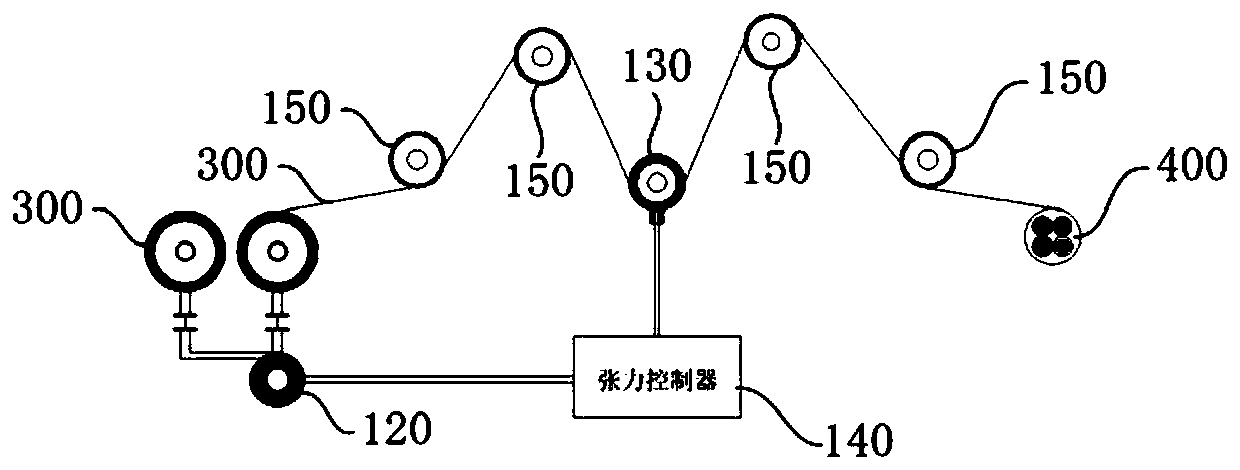

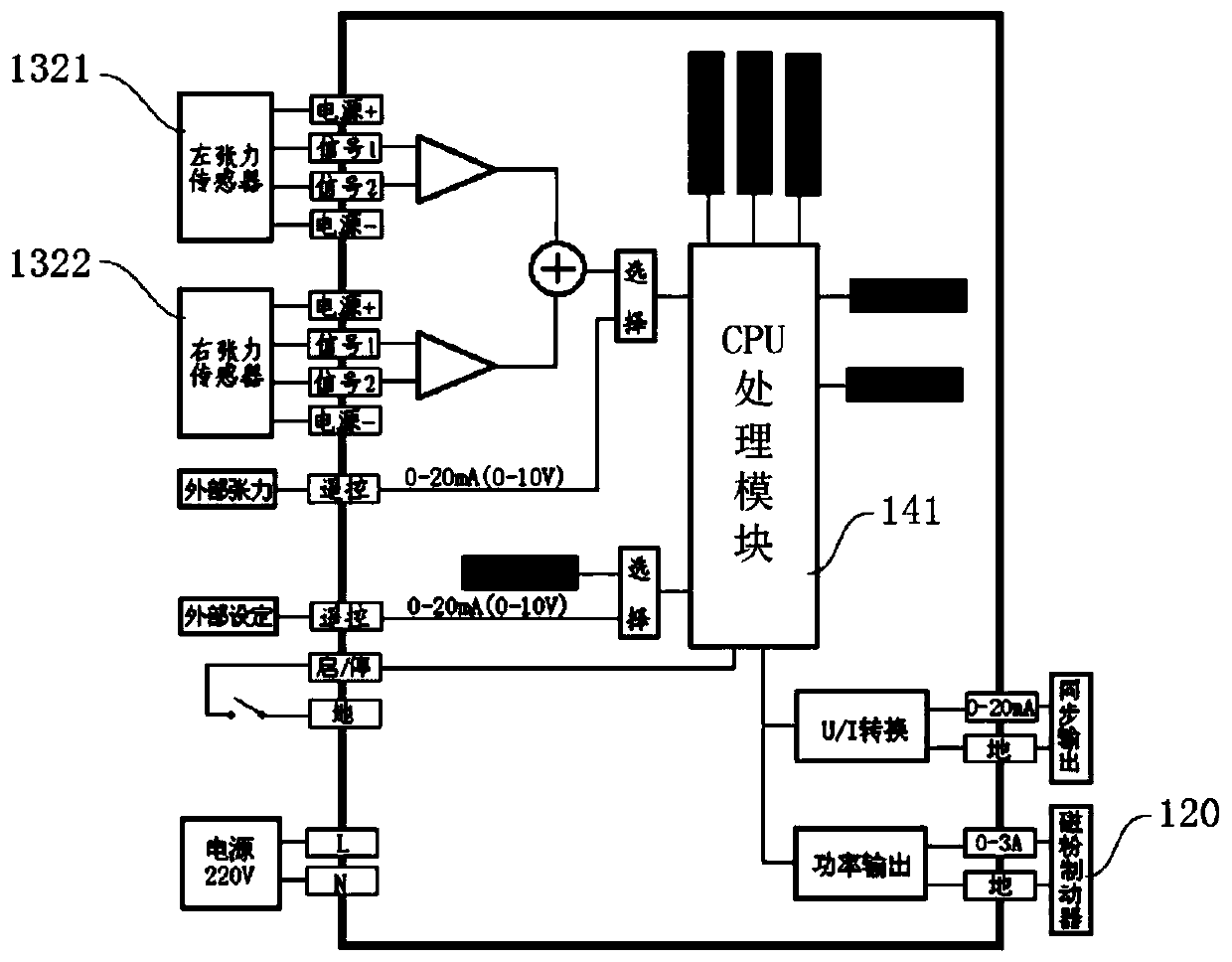

[0015] refer to Figure 1-3 , figure 1 It is a schematic diagram of the overall structure of an embodiment of the present invention, figure 2 It is a top view working principle diagram of an embodiment of the present invention, image 3 It is a control schematic diagram of a tension controller according to an embodiment of the present invention.

[0016] Such as Figure 1-2 As shown, in the embodiment of the present invention, the self-adaptive tension-adjustable tower-mounted strapping and towing machine includes: a frame 100, which is provided with two rotating shafts 110 and a magnetic powder brake 120, and the two rotating shafts 110 pass through the synchronous belt 200 transmission connection, magnetic powder brake 120 and synchronous belt 200 transmission connection.

[0017] A tower-mounted wrapping belt 300 is installed on the rotating shaft 110, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com