Building porous brick with efficient sound absorption function and preparation method thereof

A technology of sound-absorbing function and porous bricks, applied in the field of sound-absorbing building materials, can solve the problem of low sound-absorbing coefficient and achieve the effect of improving the sound-absorbing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

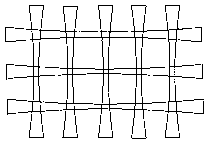

Image

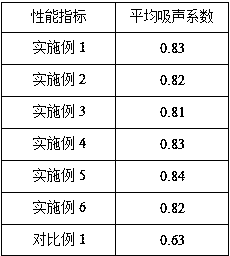

Examples

Embodiment 1

[0020] (1) Using computer modeling, polyethylene resin is used as raw material, and the resin is processed into a three-dimensional plastic mesh in the shape of a cube through 3D printing; the three-dimensional plastic mesh is composed of plastic filaments with thick ends, thin middle, and gradually changing diameters; The end diameter of the plastic wire is 3.5mm, and the middle diameter is 1.5mm; the size of the plastic net is 240mm×115mm×180mm;

[0021] (2) Take five templates (dimensions are 240mm×180mm, 240mm×115mm, 240mm×115mm, 115mm×180mm, 115mm×180mm), fit closely with the five surfaces of the plastic mesh cube respectively, and fix the templates to each other , get the mold;

[0022] (3) Pass the cement, fly ash, expansive soil and borax through a 200-mesh sieve respectively, then mix them in proportion, and add an appropriate amount of water to obtain a uniform mixture, and then add the mixture to the mold in stages, each feeding depth It is 1cm, and the next time i...

Embodiment 2

[0026] (1) Using computer modeling, polystyrene resin is used as raw material, and the resin is processed into a three-dimensional plastic mesh in the shape of a cube through 3D printing; the three-dimensional plastic mesh is composed of plastic filaments with thick ends, thin middle, and gradually changing diameters; The end diameter of the plastic wire is 3mm, and the middle diameter is 1mm; the size of the plastic mesh is 240mm×115mm×180mm;

[0027] (2) Take five templates (dimensions are 240mm×180mm, 240mm×115mm, 240mm×115mm, 115mm×180mm, 115mm×180mm), fit closely with the five surfaces of the plastic mesh cube respectively, and fix the templates to each other , get the mold;

[0028] (3) Pass the cement, fly ash, expansive soil and borax through a 200-mesh sieve respectively, then mix them in proportion, and add an appropriate amount of water to obtain a uniform mixture, and then add the mixture to the mold in stages, each feeding depth It is 1cm, and the next time is ad...

Embodiment 3

[0032] (1) Using computer modeling, polystyrene resin is used as raw material, and the resin is processed into a three-dimensional plastic mesh in the shape of a cube through 3D printing; the three-dimensional plastic mesh is composed of plastic filaments with thick ends, thin middle, and gradually changing diameters; The end diameter of the plastic wire is 3mm, and the middle diameter is 1.5mm; the size of the plastic net is 240mm×115mm×180mm;

[0033] (2) Take five templates (dimensions are 240mm×180mm, 240mm×115mm, 240mm×115mm, 115mm×180mm, 115mm×180mm), fit closely with the five surfaces of the plastic mesh cube respectively, and fix the templates to each other , get the mold;

[0034] (3) Pass the cement, fly ash, expansive soil and borax through a 200-mesh sieve respectively, then mix them in proportion, and add an appropriate amount of water to obtain a uniform mixture, and then add the mixture to the mold in stages, each feeding depth After vibrating and compacting, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com