A third-generation nickel-based single crystal superalloy that strengthens the γ′ phase and its preparation method

A high-temperature alloy and nickel-based single crystal technology, applied in the field of materials, can solve the problems of high cost, saturated content of refractory elements, unstable microstructure, etc., and achieve the effect of reducing alloy cost and low Re content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] The preparation process of the Ni-W master alloy adopts the existing technology, specifically: mix the W and Ni and load the furnace, a total of 25kg, vacuumize the melting furnace and fill it with argon, turn on the melting power supply, and then Increase the power to 100kw within 15 minutes, increase the power to 120kw after 5 minutes, and increase the power to 140kw after another 5 minutes. After the alloy is melted, reduce the power of the melting power supply to reduce the melt temperature to 1600°C. Refining for 5 minutes, then continue to reduce the power supply, and start casting when the temperature of the melt drops to 1500°C. Take it out after cooling, and thus obtain a Ni-W master alloy.

[0056] The components of each embodiment are shown in Table 1.

[0057] Table 1, unit: wt%

[0058]

[0059] For the convenience of comparison, the chemical compositions of typical third-generation nickel-based single crystal superalloys CMSX-10K, CMSX-10Ri, TMS-75 an...

Embodiment 1

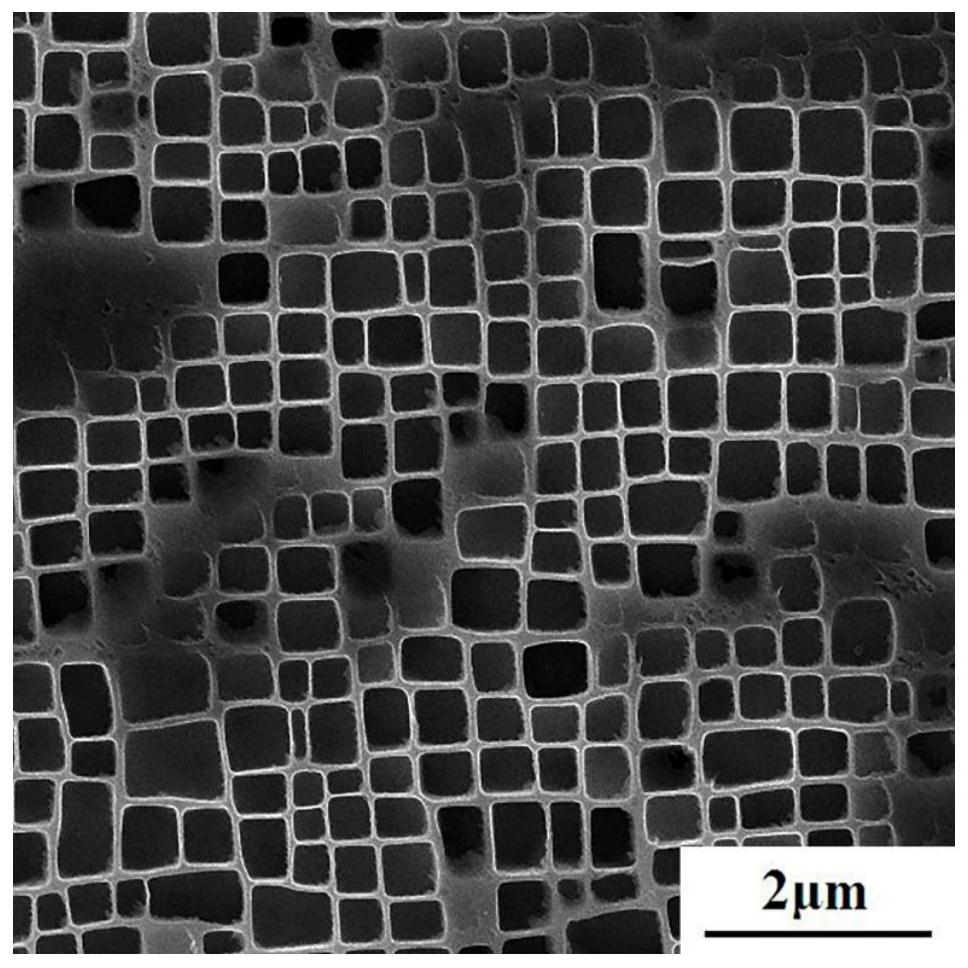

[0088] The microstructure after the complete heat treatment of embodiment 1 alloy is as follows: figure 1 As shown, the heat treatment system of the present invention is used to sufficiently diffuse the elements, and the cubic γ′ phase with a size of 0.3-0.5 mm is precipitated, and the distribution is uniform and the arrangement is regular.

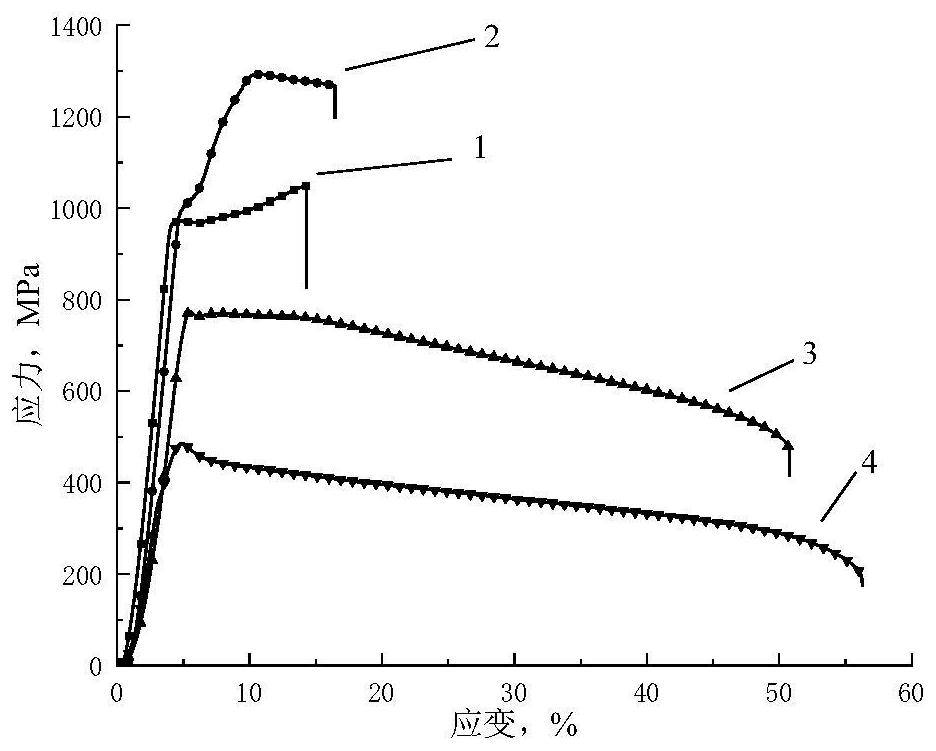

[0089] The tensile and creep properties of nickel-based single crystal superalloy samples were tested after complete heat treatment. Compared figure 2 The tensile curve 1 of the alloy in Example 1 at 20°C, the tensile curve 2 of the alloy in Example 1 at 760°C, the tensile curve 3 of the alloy in Example 1 at 980°C, and the tensile curve 3 of the alloy in Example 1 The tensile curve 4 of the alloy at 1100°C shows that when the experimental temperature rises from 20°C to 760°C, both the yield strength and tensile strength of the alloy in Example 1 increase, especially the tensile strength of the alloy increases significantly. At 980℃ an...

Embodiment 7

[0102] The properties of Example 7 under different creep conditions are shown in Table 9.

[0103] The creep properties of the third-generation nickel-based single crystal superalloy obtained in Table 9 Example 7

[0104] Creep condition Creep life h Elongation% Larson-Miller parameter P 1100℃ / 150MPa 83.6 24.91 30.10 1100℃ / 150MPa 89.4 26.57 30.14 980℃ / 350MPa 68.8 39.42 27.36 760℃ / 800MPa 220.2 25.46 23.08

[0105] Table 10 Creep performance of Example 12 at 1100°C / 150MPa

[0106] Creep condition Creep life h Elongation% Larson-Miller parameter P 1100℃ / 150MPa 78.31 21.69 30.06 1100℃ / 150MPa 81.74 9.71 30.08

[0107] Table 11 Creep performance of Example 4 at 1100°C / 150MPa

[0108] Creep condition Creep life h Elongation% Larson-Miller parameter P 1100℃ / 150MPa 46.77 28.62 29.75 1100℃ / 150MPa 38.08 33.95 29.63

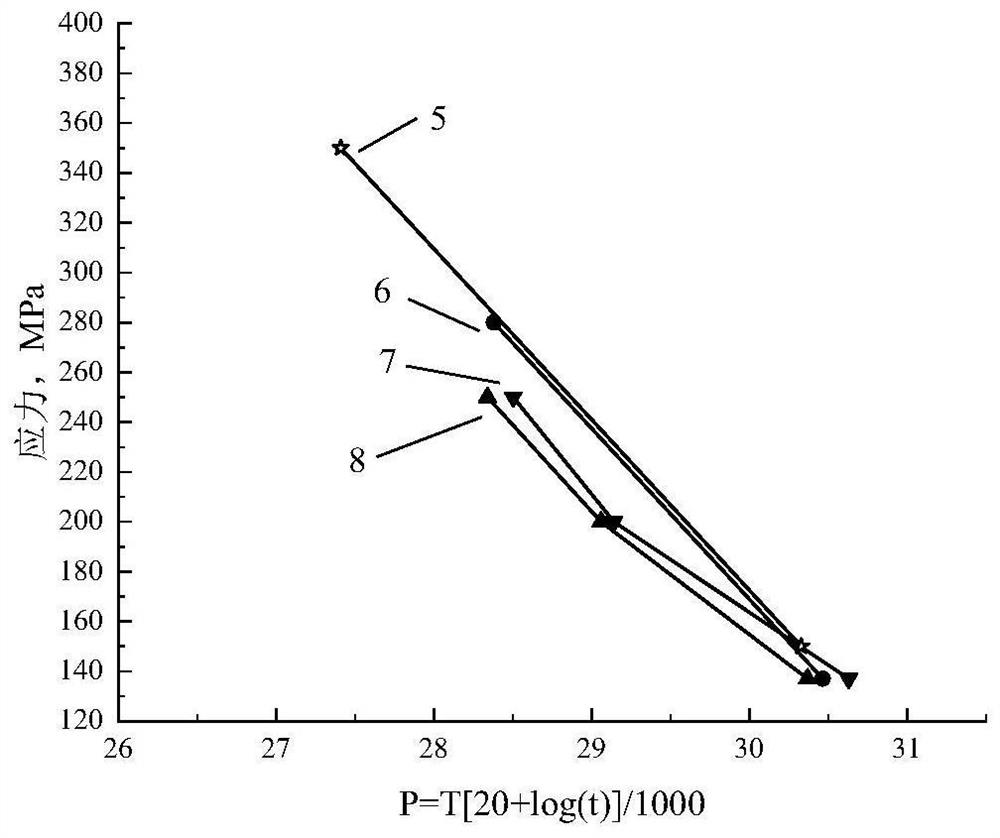

[0109] Figure 4 Among them, the proportion o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com