Environment-friendly efficient softener, and preparation method and application thereof

A softener and high-efficiency technology, applied in the field of environmentally friendly and high-efficiency softeners, can solve the problems of large amount of addition, difficulty in promotion, and high price of paper products, and achieve the effects of less usage, low cost, and reduced softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

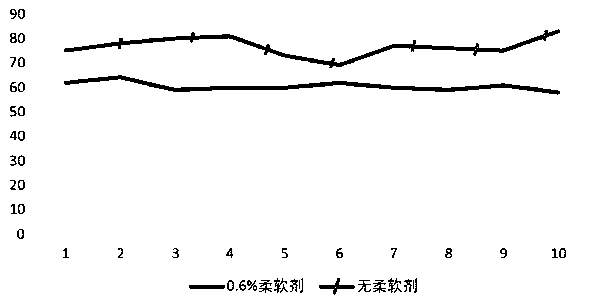

Image

Examples

Embodiment 1

[0023] An environmentally friendly and efficient softener, which is composed of the following components by weight percentage: 5% silicone resin, 30% quaternary ammonium salt polymer, 59% polyol, 0.5% emulsifier, deionized water 5%, biguanide preservatives 0.5%.

[0024] The emulsifier is alkylphenol polyoxyethylene ether, specifically octylphenol polyoxyethylene ether.

[0025] A kind of preparation method of environment-friendly high-efficiency softening agent, comprises the following steps:

[0026] 1) Take 5% of silicone resin and 30% of quaternary ammonium salt polymer, stir and mix evenly at a high speed for later use;

[0027] 2) Add 0.5% of emulsifier to polyol 59%, and add 5% of deionized water to adjust the viscosity to (2#, 200r): 30-120cps;

[0028] 3) Slowly add the mixture of silicone emulsion and quaternary ammonium salt polymer into the polyol dropwise, and keep stirring until the system becomes colorless and transparent after the dropwise addition;

[0029]...

Embodiment 2

[0031] An environmentally friendly and efficient softener, which is composed of the following components by weight percentage: 30% of silicone resin, 5% of quaternary ammonium salt polymer, 47% of polyol, 2% of emulsifier, deionized water 15%, biguanide preservatives 1.0%.

[0032] Described emulsifier is sodium dodecylbenzenesulfonate.

[0033] A kind of preparation method of environment-friendly high-efficiency softening agent, comprises the following steps:

[0034] 1) Take 30% of silicone resin and 5% of quaternary ammonium salt polymer, stir and mix evenly at a high speed for later use;

[0035] 2) Add 2% of emulsifier to 47% of polyol, and add 15% of deionized water to adjust the viscosity to (2#, 200r): 30-120cps;

[0036] 3) Slowly add the mixture of silicone emulsion and quaternary ammonium salt polymer into the polyol dropwise, and keep stirring until the system becomes colorless and transparent after the dropwise addition;

[0037] 4) Add 1.0% of biguanide preser...

Embodiment 3

[0039] An environment-friendly and high-efficiency softener, which is composed of the following components by weight percentage: 20% of silicone resin, 21% of quaternary ammonium salt polymer, 52% of polyol, 1% of emulsifier, deionized water 5.5%, biguanide preservatives 0.5%.

[0040] Described emulsifier is sodium lauryl sulfate.

[0041] A kind of preparation method of environment-friendly high-efficiency softening agent, comprises the following steps:

[0042] 1) Take 20% of silicone resin and 21% of quaternary ammonium salt polymer, stir and mix evenly at a high speed for later use;

[0043] 2) Add 1% of emulsifier to 52% of polyol, and add 5.5% of deionized water to adjust the viscosity to (2#, 200r): 30-120cps;

[0044] 3) Slowly add the mixture of silicone emulsion and quaternary ammonium salt polymer into the polyol dropwise, and keep stirring until the system becomes colorless and transparent after the dropwise addition;

[0045] 4) Add 0.5% of biguanide preservat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com