A construction method of expansive soil embankment structure for high-speed railway

A high-speed railway and expansive soil technology, applied in the field of geotechnical engineering, can solve the problems that cannot meet the deformation control requirements of high-speed railways, and achieve the effects of long deformation time, reduced settlement deformation, and controllable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

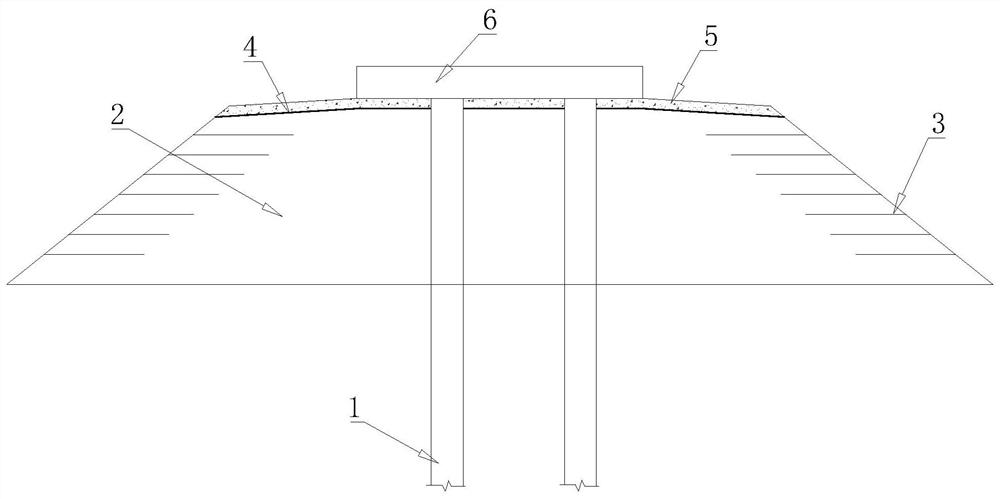

[0036] like figure 1 As shown, this embodiment provides a high-speed railway expansive soil embankment structure, including filling structure, pile structure 1, reinforcement layer 3, composite waterproof and drainage board 4 and roof structure 6;

[0037] The filling structure includes the filling surface structure 5 and the filling substructure 2. The filling substructure 2 is filled in layers above the foundation, and the filling surface structure 5 is filled above the filling substructure 2. Specifically, the filling The substructure 2 is made of expansive soil, and the filling surface structure 5 is made of A and B groups of fillers.

[0038] The pile structure 1 is buried in the foundation and runs through the fill structure. The top of the pile structure 1 protrudes from the fill surface structure 5 and is fixedly connected with the roof structure 6. At least two rows of pile structures 1 are arranged at intervals along the width direction of the line. Each row of piles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com