A modular construction method for nuclear power reactor cavity pool

A construction method and a modular technology, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of large construction period, long construction period, and many processes, so as to improve construction efficiency, save construction period, and reduce processes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

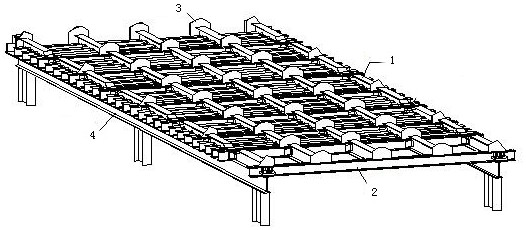

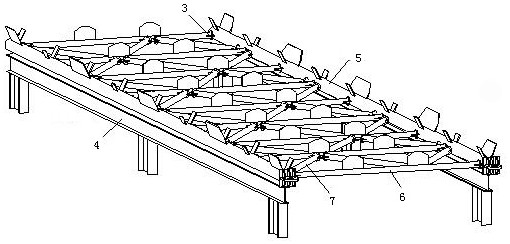

[0069] The present invention will be further described below in conjunction with the accompanying drawings and specific preferred embodiments.

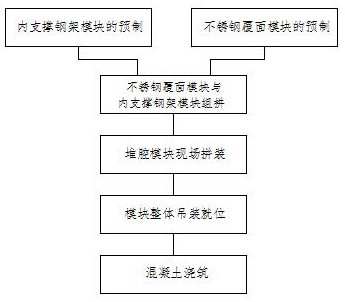

[0070] A nuclear power reactor cavity pool modular construction method, the nuclear power reactor cavity pool includes several pool wall sub-modules that can be disassembled, the specific method of the nuclear power reactor cavity pool modular construction method is:

[0071] Step 1: Prefabrication of inner supporting steel frame modules;

[0072] Step 2: Prefabrication of stainless steel cladding modules;

[0073] Step 3: Assemble the stainless steel cladding module and the inner supporting steel frame module;

[0074] Step 4: On-site assembly of the stack cavity module;

[0075] Step 5: The module is hoisted in place as a whole;

[0076] Step 6: Concrete pouring.

[0077] In this embodiment, the specific implementation steps of step 1 include:

[0078] Step 1.1: Assemble and weld steel mesh pieces;

[0079] Step 1.2: Assemblin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com