An exposed aggregate ceramsite permeable concrete road structure based on solid waste recycling

A technology for permeable concrete and road structures, which is applied to the coagulation pavement, roads, roads and other directions of on-site paving, can solve the problems of poor wear resistance of exposed aggregate permeable concrete ground, reduced water permeability, inability to absorb and filter dust and impurities, etc. Achieve the effect of protecting the natural ecological environment, preventing pedestrian safety problems, and overcoming uneven settlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The exposed aggregate fly ash unburned ceramsite permeable concrete layer 5 is prepared by the following preparation method, which specifically includes the following steps:

[0041] Step 1: Fly ash, slag, lime, and cement materials are prepared by plasticizing, granulating, and autoclaving processes to prepare fly ash unfired ceramsite;

[0042] Step 2: Fly ash unfired ceramsite and fly ash unfired ceramsite are the main aggregates, supplemented with cement, reinforcing agent and water to form fly ash unburned ceramsite permeable concrete;

[0043] Step 3: The fly ash unburned ceramsite permeable concrete layer is poured into the formed fly ash unburned ceramsite permeable concrete material as the main aggregate;

[0044] Step 4: After the fly ash unburned ceramsite permeable concrete layer is poured, spray the surface exposed agent atomized liquid on its surface, and immediately use plastic film materials to cover and maintain the surface after spraying;

[0045] Ste...

Embodiment 1

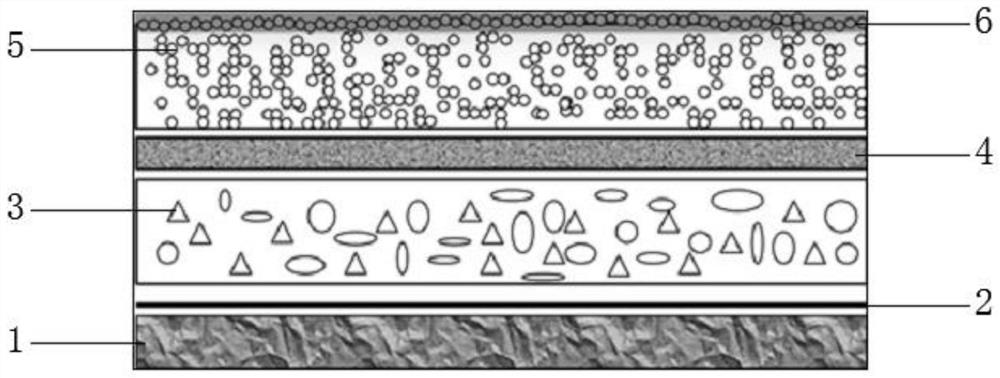

[0055] Combine below figure 1 To illustrate this embodiment, the present invention relates to the technical field of exposed aggregate ceramsite permeable concrete, more specifically, a structure of exposed aggregate ceramsite permeable concrete based on solid waste reuse, including: a base layer 1, a reverse filter layer 2, an urban building Garbage recycled aggregate cushion layer 3, fly ash unburned ceramsite sand filter layer 4, exposed aggregate fly ash unburned ceramsite permeable concrete layer 5 and overcoat agent layer 6.

[0056] The base layer 1 is the bottom layer, the reverse filter layer 2 is set above the base layer 1, the urban construction waste recycled aggregate cushion layer 3 is set above the reverse filter layer 2, and the fly ash unburned pottery sand filter layer 4 is set above the urban construction waste recycling Above the aggregate cushion layer 3, the exposed aggregate fly ash unburned ceramsite permeable concrete layer 5 is set above the fly ash u...

Embodiment 2

[0059] Combine below figure 1 Illustrate this embodiment. This embodiment will further illustrate Embodiment 1. The reverse filter layer 2 adopts needle-punched short-filament geotextiles, the tensile strength of the geotextiles at break is 28MPa, and the elongation at break is 725%; It is composed of crushed waste bricks, with an average particle size of about 10mm and a thickness of 200mm; the fly ash unfired ceramic sand filter layer 4 adopts fly ash unfired ceramic sand GD-TS05 with a particle size of 0.5mm, and the thickness of the layer is 30cm; the exposed aggregate fly ash unburned ceramsite permeable concrete layer 5 is formed by pouring the permeable concrete material with fly ash unburned ceramsite as the main aggregate, the porosity is about 20%, and the pouring thickness is 150mm. Zhu TM-Concrete Surface Exposure Agent's "surface erosion with controllable depth" technology realizes the exposure of aggregate on the upper surface, and the aggregate depth is 3mm; the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com