Production method of super soy sauce

A production method and technology for soy sauce, which are applied in the field of condiment production, can solve the problems of poor control of the amount of yeast extract added, pollution by chloropropanol carcinogens, adverse effects on the flavor of soy sauce, etc. Optimize, optimize the effect of the brewing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

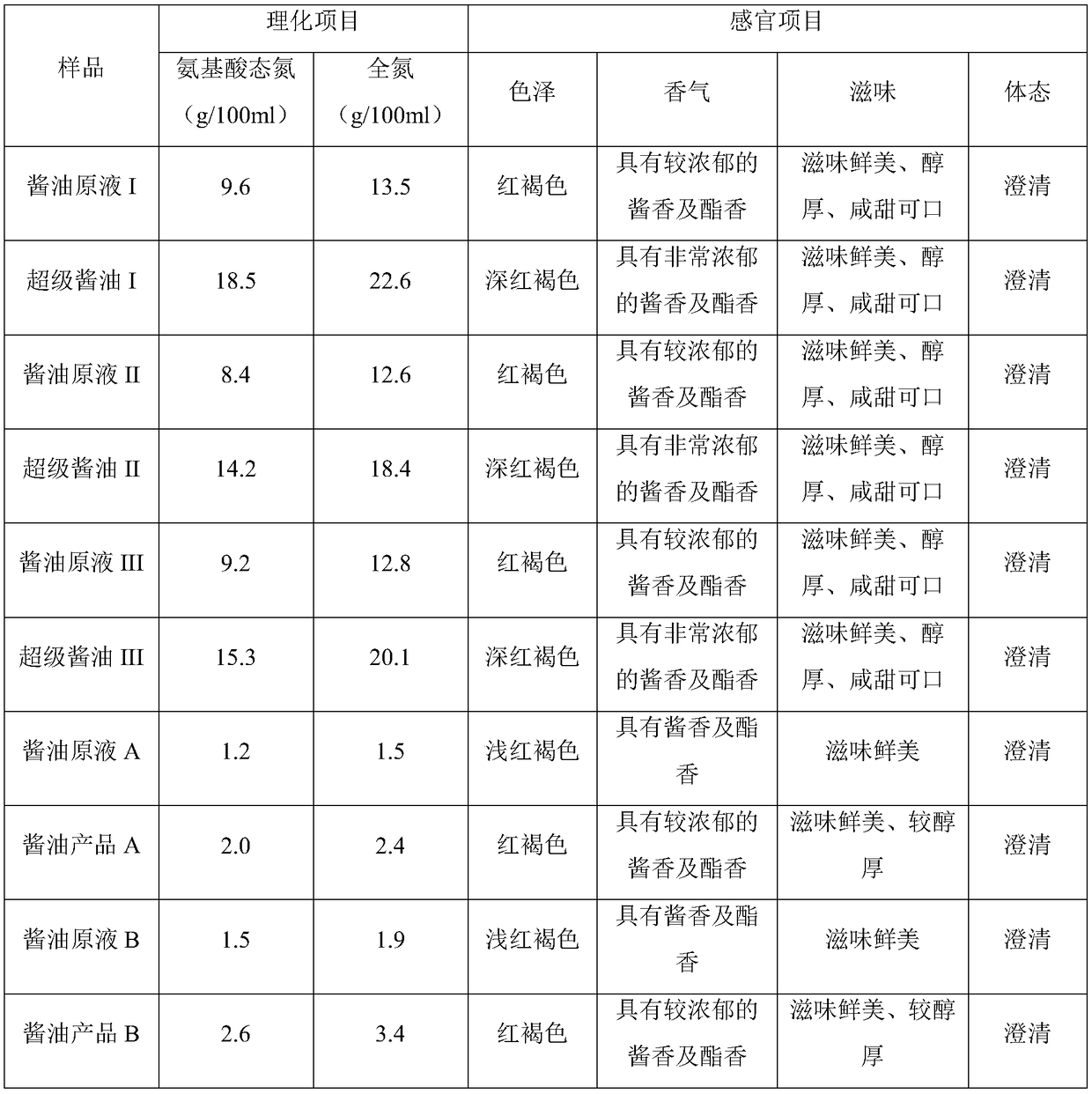

[0039] Embodiment 1: the preparation of super soy sauce

[0040] (1) Take soybean meal and bran as raw materials for cooking, and the mass ratio of soybean meal and bran is 3:1. The cooking conditions are as follows: the cooking temperature is 120° C., and the cooking time is 10 minutes. Cool after cooking.

[0041] (2) Inoculate 1‰ (w / w) koji species into the cooled raw material, the koji species are mixed by Aspergillus oryzae and lactic acid bacteria at a mass ratio of 2:1, the koji making conditions are: first at a temperature of 23 Cultivate for 12 hours under the conditions of 32° C. and 75% humidity; then cultivate for 32 hours under the conditions of 32° C. and 85 percent humidity to obtain soy sauce dako.

[0042] (3) mix soy sauce daqu and salt water containing sodium alginate at a mass ratio of 1:4 to make moromi, the content of sodium alginate in the salt water containing sodium alginate is 3% (mass percentage), and the The salt content of brine is 15g / 100ml.

...

Embodiment 2

[0045] Embodiment 2: the preparation of super soy sauce

[0046] (1) Take soybean meal and bran as raw materials for cooking, and the mass ratio of soybean meal and bran is 2:1. The cooking conditions are as follows: the cooking temperature is 130° C., and the cooking time is 5 minutes. Cool after cooking.

[0047] (2) Inoculate 0.5‰ (w / w) koji species into the cooled raw material, the koji species are mixed by Aspergillus oryzae and lactic acid bacteria at a mass ratio of 2:1, the koji making conditions are: first at a temperature of 20 Cultivate for 8 hours under the conditions of 30°C and 65% humidity; then cultivate for 24 hours under the conditions of 30°C and 70% humidity to obtain soy sauce dako.

[0048] (3) mix soy sauce daqu and salt water containing sodium alginate at a mass ratio of 1:3 to make moromi, the content of sodium alginate in the salt water containing sodium alginate is 2% (mass percentage), and the The salt content of brine is 10g / 100ml.

[0049] (4)...

Embodiment 3

[0051] Embodiment 3: the preparation of super soy sauce

[0052] (1) Take soybean meal and bran as raw materials for cooking, and the mass ratio of soybean meal and bran is 4:1. The cooking conditions are as follows: the cooking temperature is 110° C., and the cooking time is 10 minutes. Cool after cooking.

[0053] (2) Inoculate 1.5‰ (w / w) koji species into the cooled raw material, the koji species are mixed by Aspergillus oryzae and lactic acid bacteria at a mass ratio of 2:1, the koji making conditions are: first at a temperature of 25 Cultivate for 12 hours under the conditions of 35° C. and 85% humidity, and then cultivate for 36 hours under the conditions of 35° C. and 95 percent humidity to obtain soy sauce dako.

[0054] (3) mix soy sauce daqu and brine containing sodium alginate at a mass ratio of 1:3 to make moromi, the content of sodium alginate in the brine containing sodium alginate is 4% (mass percentage), the The salt content of brine is 15g / 100ml.

[0055] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com