Multiple-effect azole microcapsule suspension formulation with slow-release function and preparation method thereof

A technology of microcapsule suspension and azole microcapsules is applied in the fields of botanical equipment and methods, biocides, animal repellents, etc. The effect of protecting the natural ecological environment and reducing the risk of phytotoxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

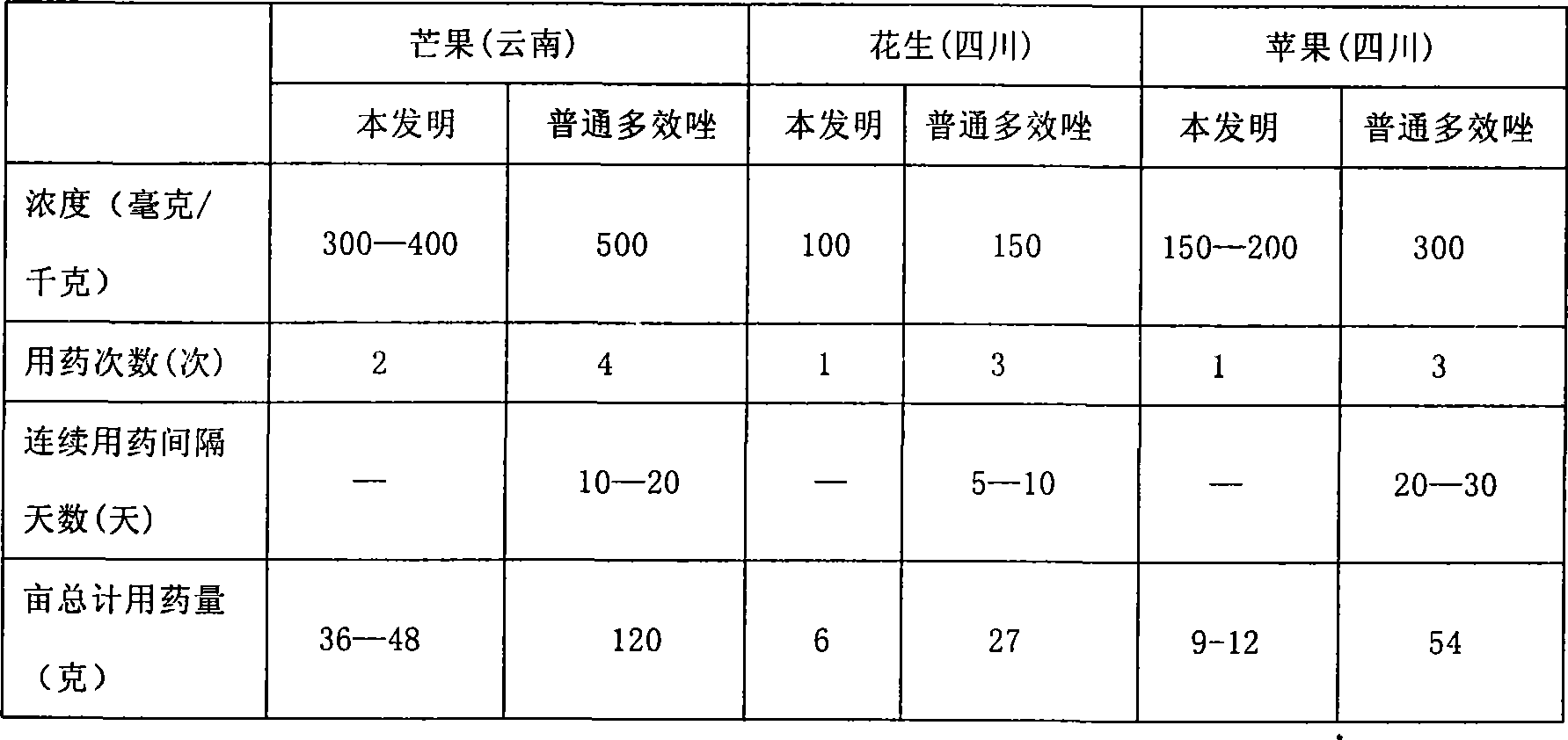

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The Paclobutrazol microcapsule suspension preparation with sustained-release function in Example 1 is composed of the following components based on 100 parts by weight:

[0023] Polytoluene-2,4-diisocyanate 10 parts

[0024] Ethylenediamine 4 parts

[0025] Paclobutrazol 5 parts

[0026] Alkylphenol polyoxyethylene ether 11 parts

[0027] 70 parts of water,

[0028] The preparation method of the preparation of Example 1 is to proportion the ingredients. Stir the polytoluene-2,4-diisocyanate and ethylenediamine at a speed of 150r / min for 1 hour, and put the paclobutrazol into the stirred polytoluene-2,4 —Diisohydrogen acid ester, ethylenediamine, under 35℃±5℃ temperature and normal pressure, stirred and reacted at 200r / min speed for 1 hour to prepare capsule-capsule core complex, and then add alkyl Phenol polyoxyethylene ether is multidimensionally emulsified for 0.5 hours, and finally added to water. In the water phase, the micro-emulsification is continued for 2 hours under the...

Embodiment 2

[0030] The Paclobutrazol microcapsule suspension preparation with sustained-release function in Example 2 is composed of the following components based on 100 parts by weight:

[0031] Carboxymethyl cellulose 15 parts

[0032] 7 parts of diethylene triamine

[0033] Paclobutrazol 20 parts

[0034] Alkyl polyglycoside 11 parts

[0035] 47 parts of water

[0036] The preparation method of the preparation of Example 2 is to proportion the ingredients. Stir the carboxymethyl cellulose and diethylene triamine for 1.5 hours at a rotating speed of 100r / min, and put the paclobutrazol into the stirred hydroxymethyl cellulose, In diethylene triamine, at 45℃±5℃, under normal pressure, 1200r / min stirring and reacting for 1 hour, the capsule membrane-capsule core complex is prepared, and then the alkyl polyglycoside is added for multidimensional emulsification for 0.5 hours. Finally, add water, continue to emulsify for 2 hours under stirring conditions of 500r / min in the water phase, check the part...

Embodiment 3

[0038] In Example 3, the paclobutrazol microcapsule suspension preparation with sustained-release function is composed of the following components based on 100 parts by weight:

[0039] 20 parts of polyvinylpyrrolidone

[0040] 10 parts of polyethylene glycol

[0041] Paclobutrazol 40 parts

[0042] Quaternary Ammonium Glucoside 8 parts

[0043] 22 parts water

[0044] The preparation method of the preparation of Example 3 is to proportion the ingredients. Stir the polyethylene glycol and polyvinylpyrrolidone at a speed of 200r / min for 1 hour, and put the paclobutrazol into the stirred polyethylene glycol and polyvinylpyrrolidone. In the medium, under 65℃±5℃ temperature and normal pressure, 1200r / min stirring and reacting for 2 hours, the capsule core complex is prepared, and the quaternary ammonium glucoside is added for multidimensional emulsification for 1 hour, and finally added to water, in the water phase The emulsification is continued for 3 hours under the stirring condition of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com