Flash boiling steam humidifier

A technology of steam humidifier and heater, which is applied in the direction of air humidification system, heating method, lighting and heating equipment, etc. It can solve the problems of high ambient air flow velocity, bacterial pollution, and lower ambient temperature, so as to avoid mold pollution and avoid Air cooling and high humidification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

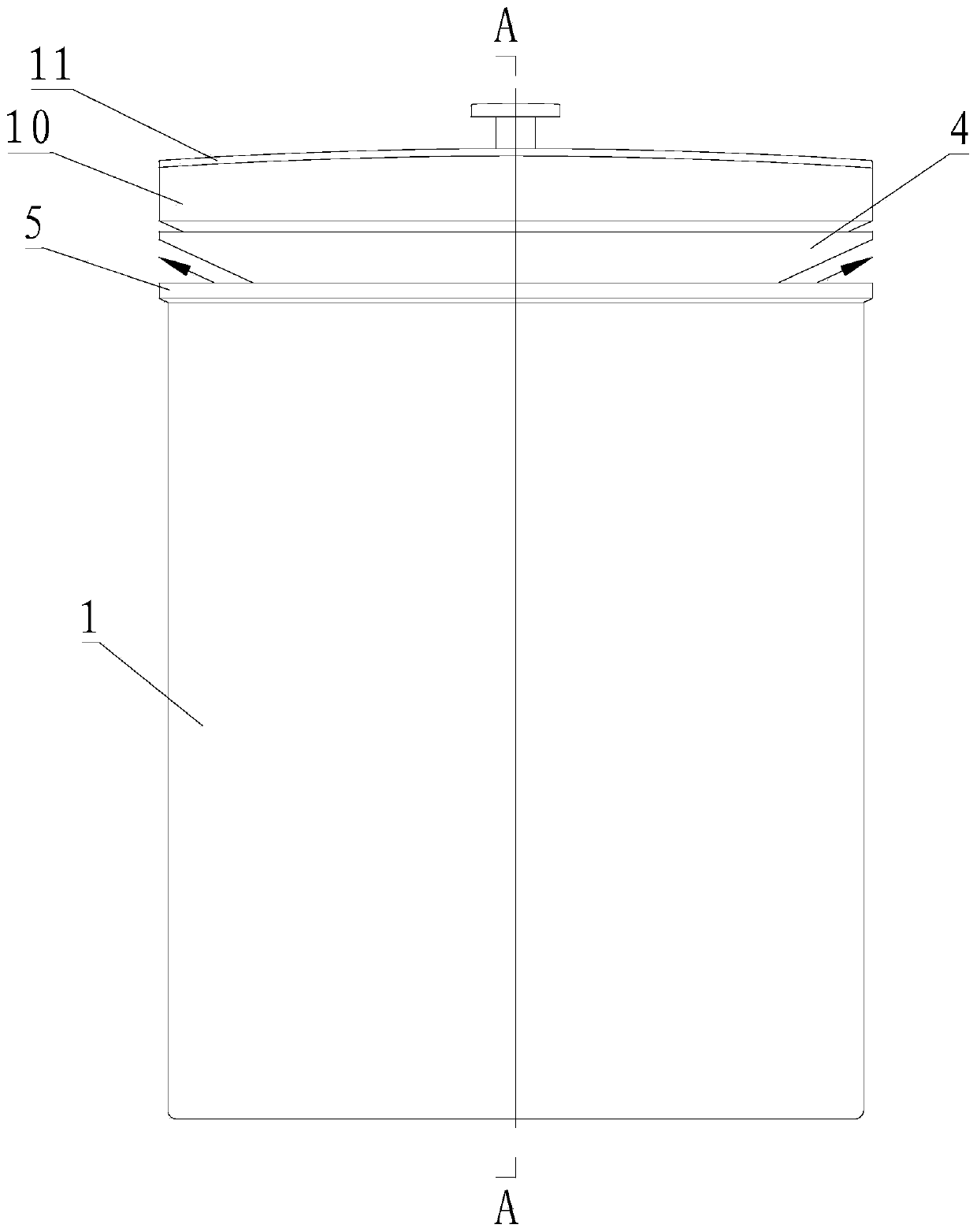

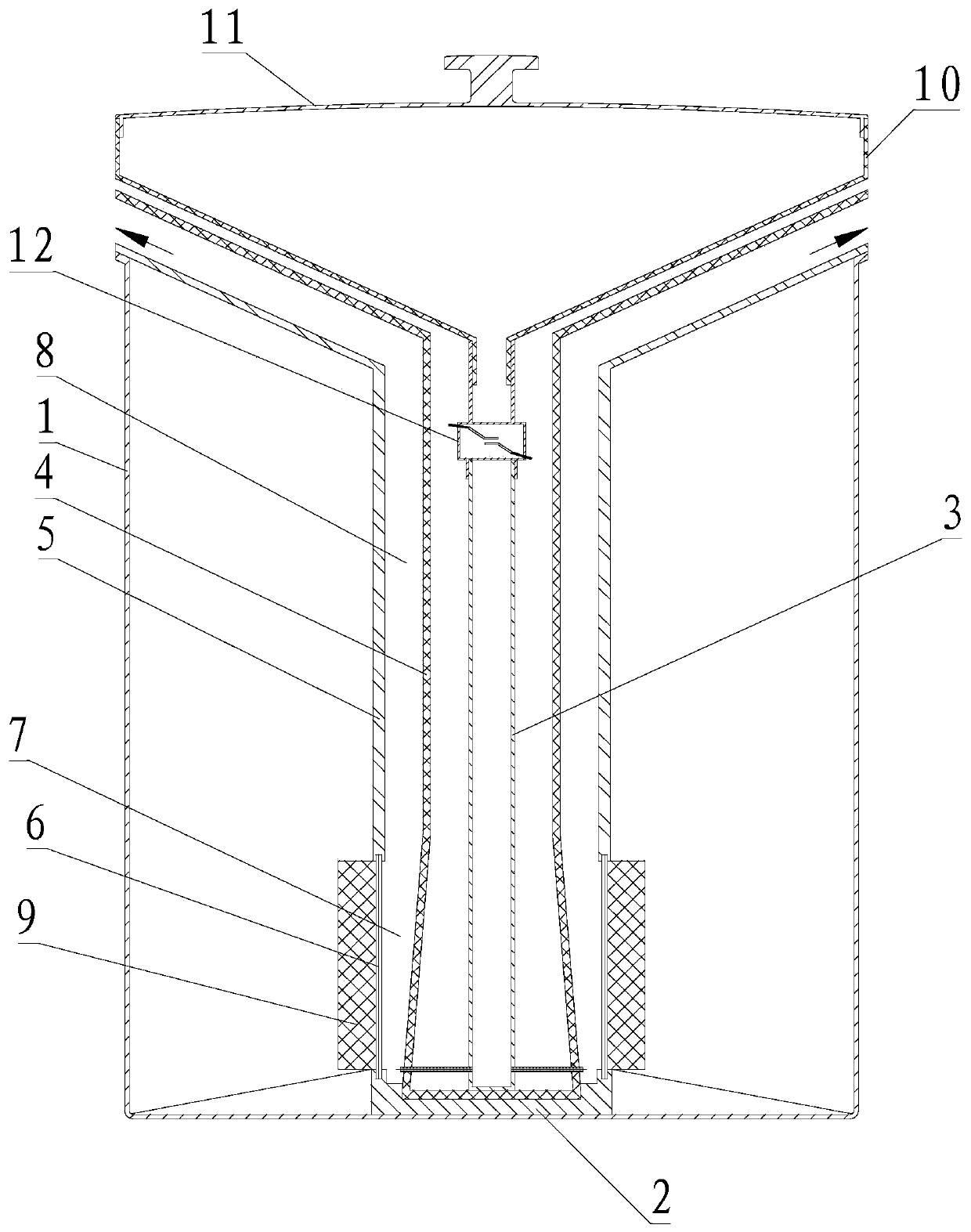

[0052] see Figure 1 to Figure 12 , a flashing steam humidifier, including a housing 1, a fixed seat 2, a static pressure standpipe 3, a first draft tube 4, a second draft tube 5, a tubular electric heater 6 and a water tank 10, the The static pressure standpipe 3, the first flow guide pipe 4 and the tubular electric heater 6 are all tubular structures, wherein the outer diameter of the static pressure standpipe 3 is less than the inner diameter of the first flow guide pipe 4, and the first flow guide pipe The outer diameter of 4 is smaller than the inner diameter of the tubular electric heater 6, and the static pressure standpipe 3, the first draft tube 4 and the tubular electric heater 6 are sequentially arranged on the fixed seat 2 from the inside to the outside , the fixed seat 2 is fixed in the housing 1, the lower end of the second guide tube 5 is connected to the upper end of the tubular electric heater 6, and the bottom of the water tank 10 is provided with a water out...

Embodiment 2

[0058] On the basis of Embodiment 1, the first guide pipe 4 includes a tapered section 401, an equal-diameter section 402 and a first bell mouth section 403 arranged in sequence from bottom to top;

[0059] The second draft tube 5 includes a straight-through section 501 and a second bell-mouth section 502 arranged in sequence from bottom to top.

[0060] In this embodiment, a steam channel 8 is formed between the equal-diameter section 402 and the first bell-mouth section 403 of the first draft tube and the straight-through section 501 and the second bell-mouth section 502 of the second draft tube, which can guide steam Steering, effectively extending the coverage of the steam.

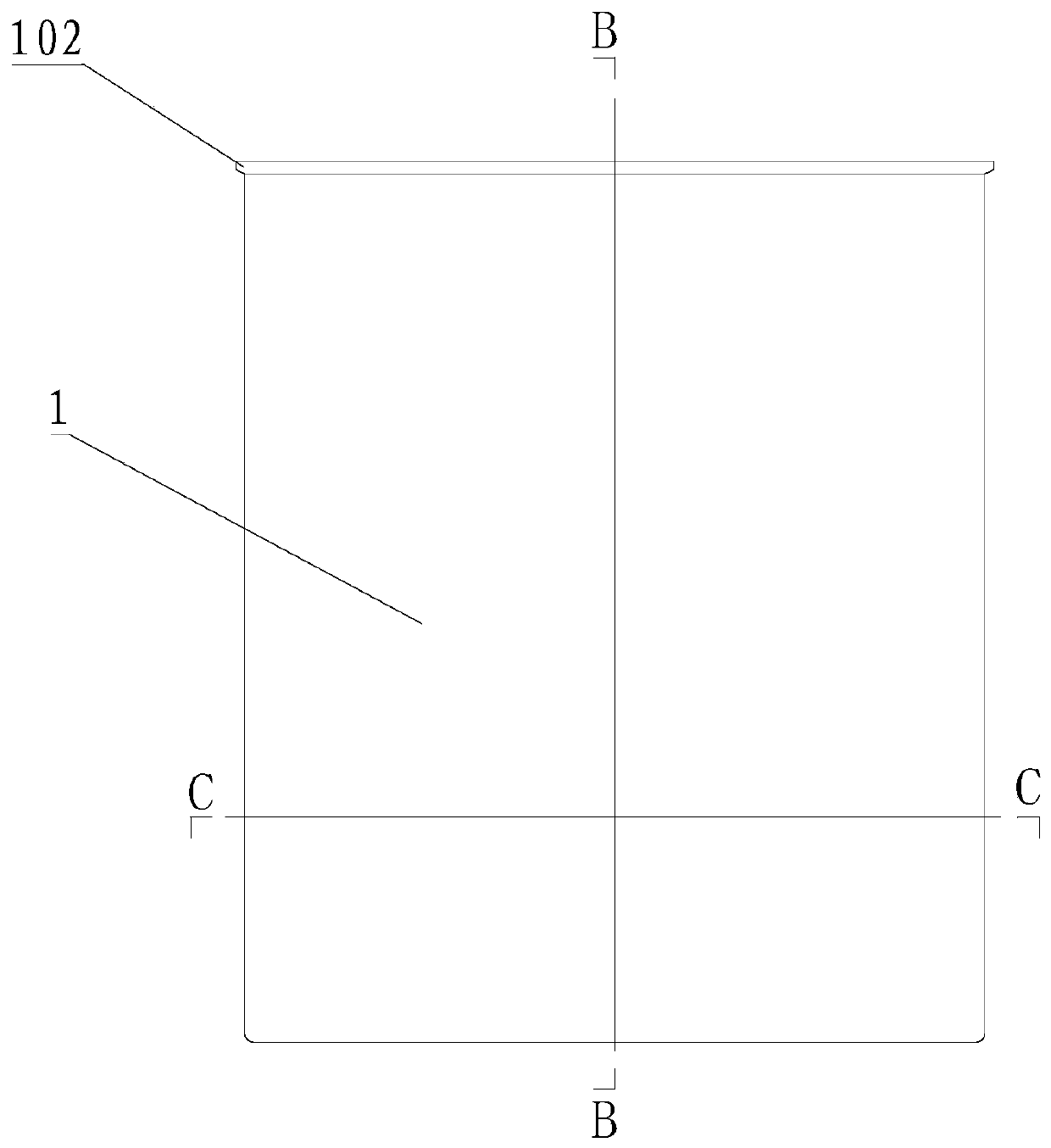

[0061] Preferably, the second bell mouth section 502 of the second draft tube 5 is ultrasonically welded to the outer skimming edge 102 of the upper end of the casing.

Embodiment 3

[0063] On the basis of Example 2, a vaporization chamber 7 is formed between the 4 tapered sections 401 of the first draft tube and the tubular electric heater 6, and the vaporization chamber 7 includes a flow area, and the flow area The area increases gradually from bottom to top.

[0064] In this embodiment, the flow area of the vaporization chamber gradually increases from bottom to top, and the suddenly vaporized water vapor expands rapidly in the vaporization chamber under the effect of volume enlargement, and then forms a The unique steam flow path is sprayed to the outside of the shell of the flash steam humidifier, which can significantly expand the steam coverage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com