A Chemical Trimming Method for Second Harmonic Error of Quartz Cylindrical Harmonic Oscillator

A harmonic oscillator and sub-harmonic technology, applied in the direction of instruments, measuring devices, steering sensing equipment, etc., can solve the problems of restricting the accuracy of vibrating gyroscopes and deterioration of gyroscope performance, achieve low cost, meet needs, and reduce the second harmonic The effect of the error value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

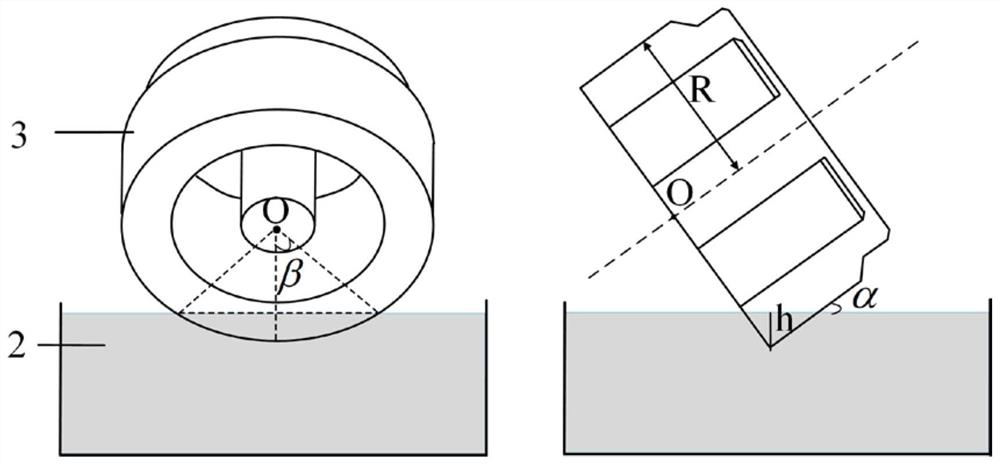

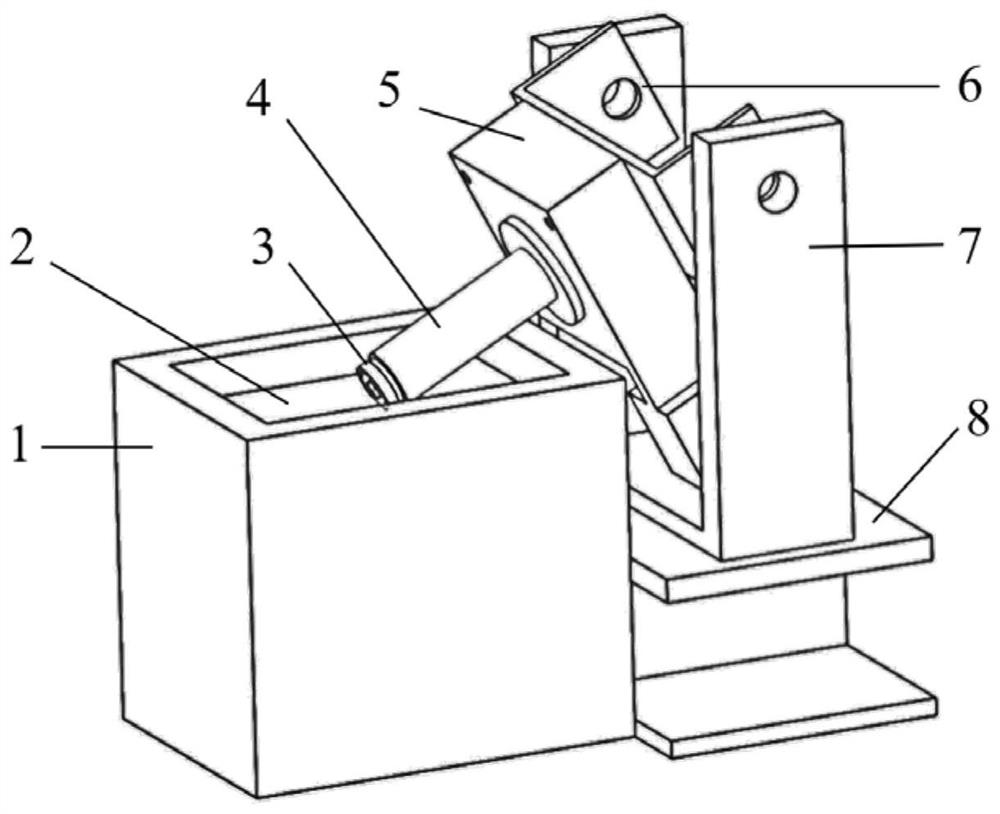

[0045] Quartz cylindrical shell harmonic oscillator modification system, such as image 3 As shown, it includes a constant temperature solution tank 1, a chemical etching solution 2, a cylindrical shell resonator 3, a resonator mount 4, a rotating table 5, an angle adjustment mechanism 6, an adapter plate 7, and a vertical displacement table 8; the resonator 3 Installed on the resonator mounting base 4 and connected to the rotating platform 5; the angle adjustment mechanism 6 is installed on the vertical displacement platform 8 through the adapter plate 7.

[0046]The constant temperature solution tank 1 is made of polytetrafluoroethylene, and is used to store highly corrosive chemical etching solution and keep the temperature of the chemical etching solution constant.

[0047] The chemical etchant 2 is composed of 49% HF solution and 40% N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com