A reinforced anti-rotation expanded beam optical fiber contact

A technology of beam expanding optical fiber and contacts, which is applied in the field of beam expanding optical fiber contacts, can solve the problems that the light spot becomes very sensitive to the axis angle, the repeatability of the test results is poor, and the quality of the optical core number transmission is affected, so as to improve the repeatability The effect of avoiding axis deviation and insertion loss and improving work reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

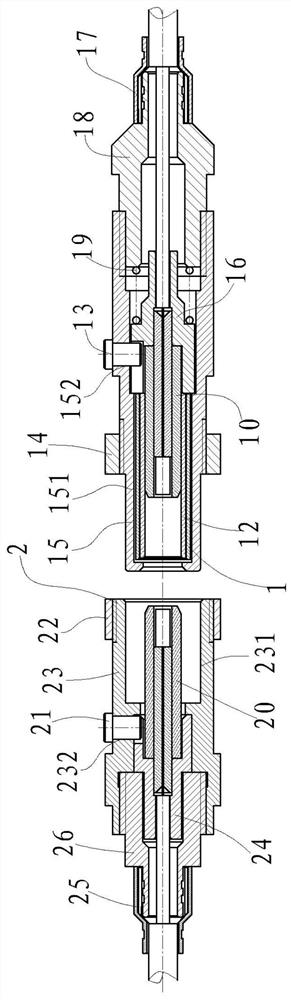

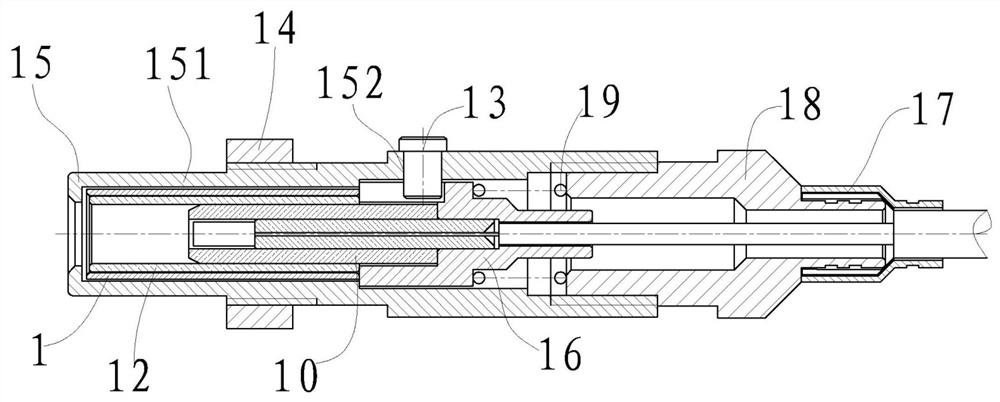

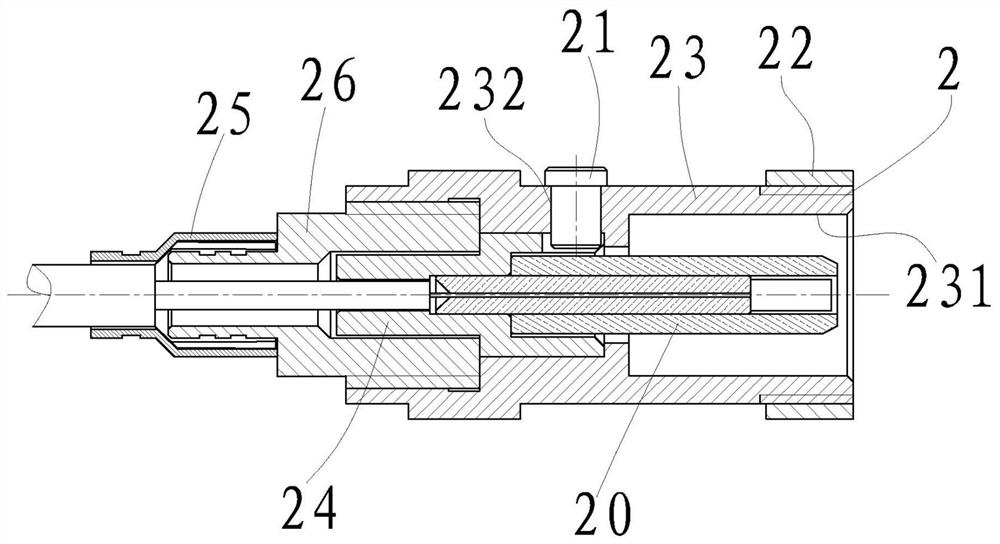

[0034] refer to figure 1 , the present invention includes an optical fiber ferrule 1 and an optical fiber jack 2;

[0035] refer to figure 1 , figure 2 , the optical fiber ferrule 1 is composed of a first beam expanding ferrule 10, a protective tube 11, a ceramic sleeve 12, a first anti-rotation pin 13, a first nut 14, a needle housing 15, a needle tail handle 16, a first press Sleeve 17, needle sleeve 18 and spring 19 constitute;

[0036] The needle housing 15 is a cylindrical member with a stepped hole and an internal thread inside, and an external thread and a guide column 151 outside, and a first pin hole 152 is provided on the wall of the cylinder.

[0037] refer to figure 1 , figure 2 , Figure 4 , the needle tail handle 16 is a cylindrical member with a stepped hole inside and a spring seat outside, and a first keyway 161 is provided on the wall of the cylinder.

[0038] refer to figure 1 , figure 2 , the needle sleeve 18 is a cylindrical member with an exte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com