Stator core cooling structure and motor cooling system

A stator core and cooling structure technology, applied in the direction of cooling/ventilation device, magnetic circuit shape/style/structure, winding conductor shape/style/structure, etc., can solve high manufacturing cost, long processing cycle and cumbersome assembly process and other problems, to achieve the effect of solving long processing cycle, high cooling efficiency and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

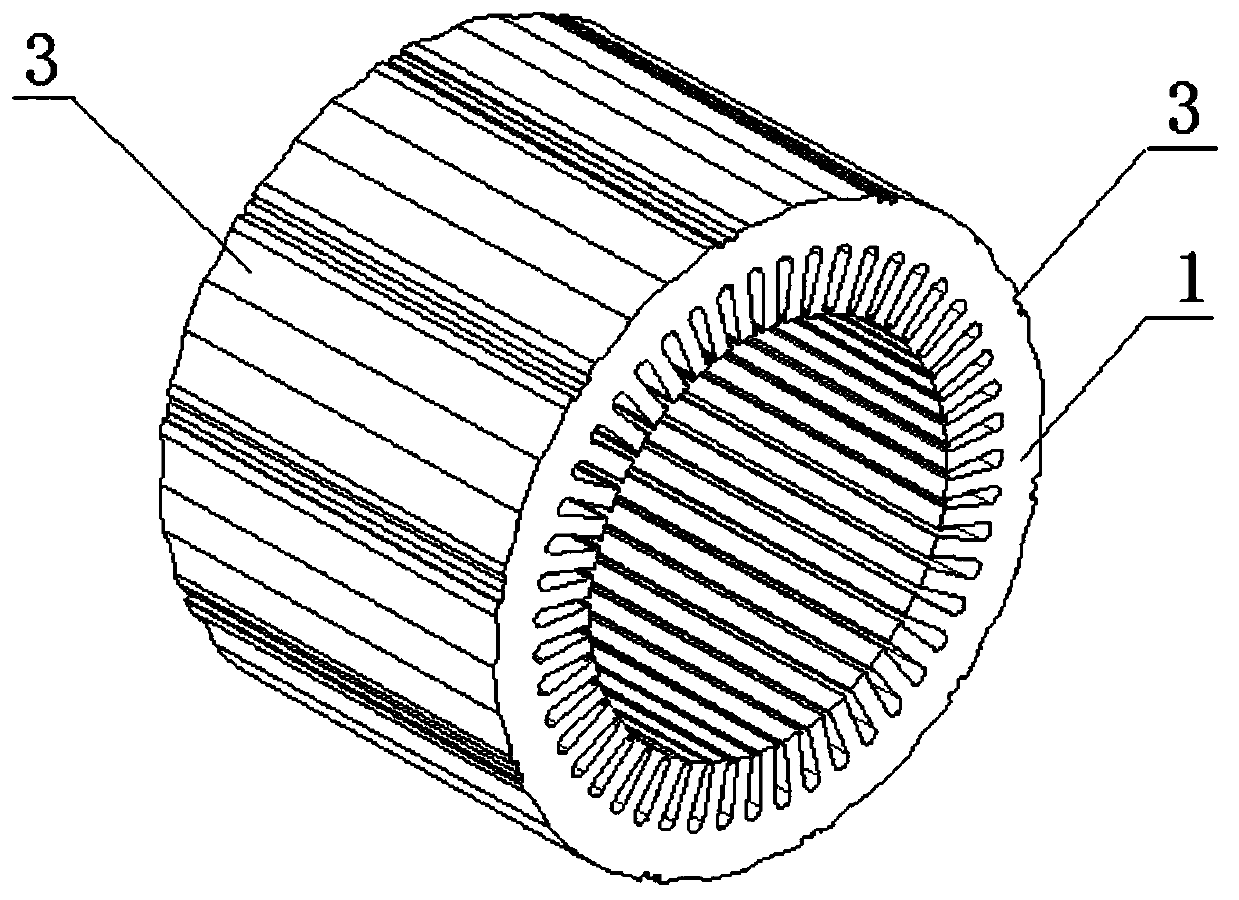

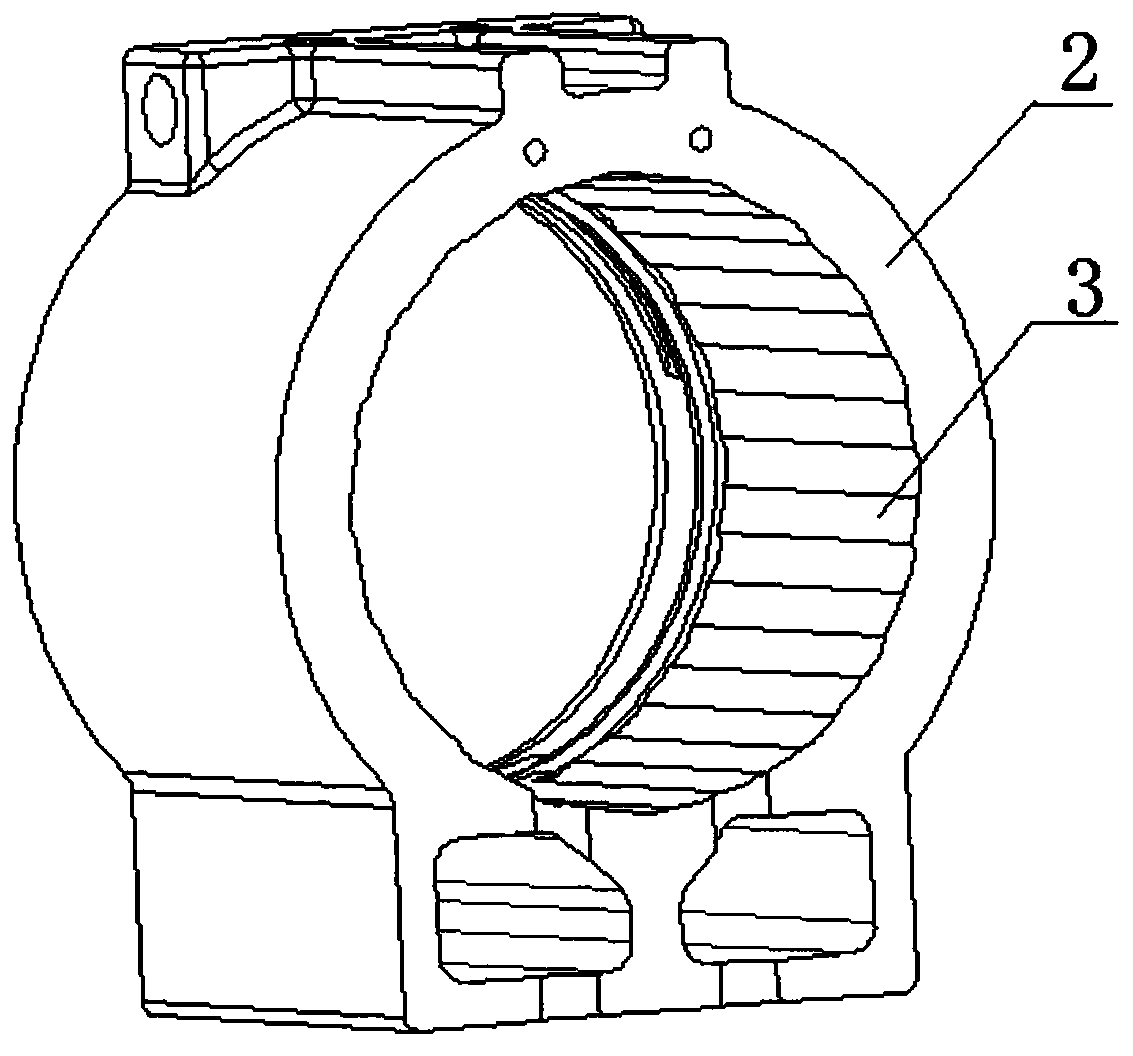

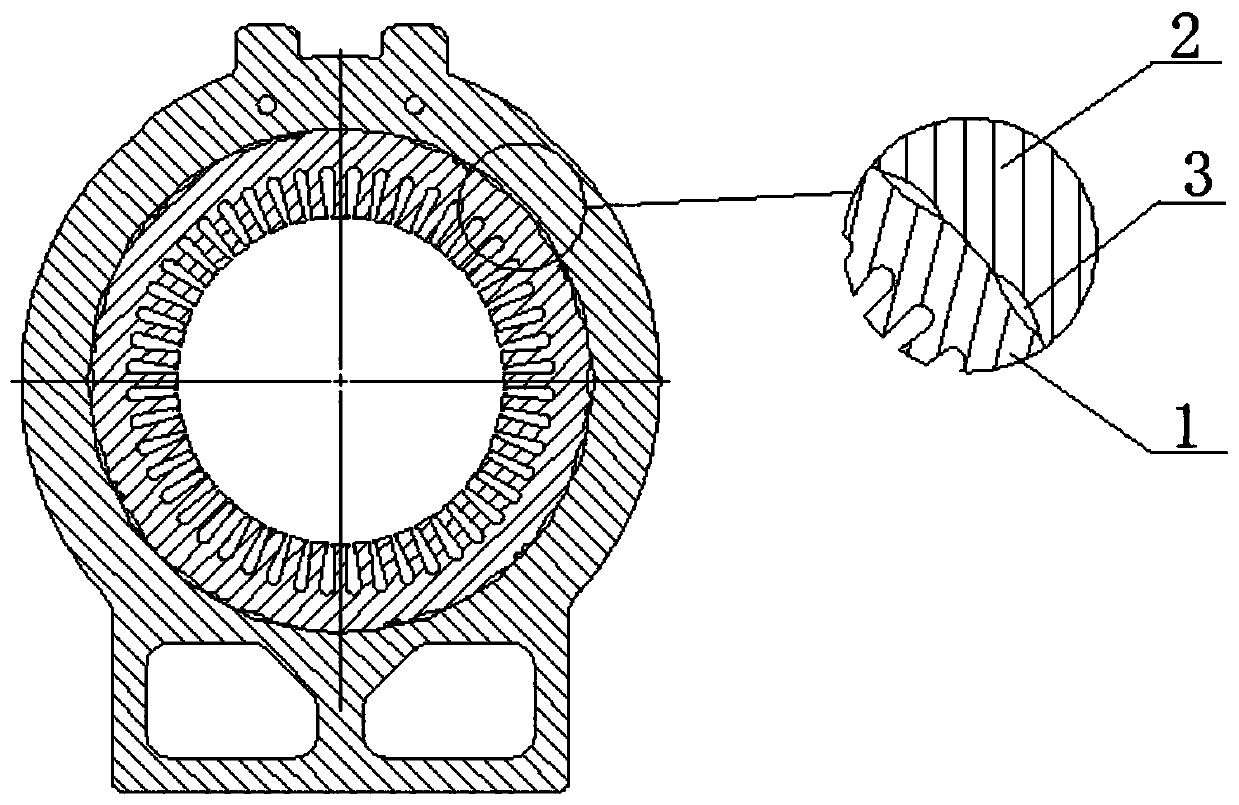

[0040] The embodiment of the invention discloses a stator core cooling structure, which includes a stator core 1 and a motor housing 2 .

[0041] Such as Figure 1-2 As shown, a number of axial grooves 3 are distributed on the outer circumference of the stator core 1 and / or the inner circumference of the motor housing 2, and the axial grooves 3 can be groove structures of various shapes, such as arc-shaped groove, V-shaped groove, polygonal groove, etc., the axial groove 3 extends in the axial direction of the stator core 1 and / or the motor housing 2, and the axial groove 3 provided on the stator core 1 runs through the entire stator iron Core 1, the axial groove 3 provided on the motor housing 2 extends longer than the thickness of the stator core 1, and the axial groove 3 on the motor housing 2 is facing the stator core 1; the axial groove 3. The number of sets and the distribution of positions can be adjusted according to actual needs.

[0042] The stator core 1 is assemb...

Embodiment 2

[0048] The embodiment of the invention also discloses a motor cooling system, such as Figure 4-6 As shown, the motor cooling system includes a liquid inlet 5 , a liquid inlet channel 6 , a liquid separation channel, any of the stator core cooling structures described above, and a liquid outlet 8 .

[0049] The liquid inlet 5 arranged above the motor housing 2 communicates with the cooling structure of the stator core through the liquid inlet channel 6 and the liquid separation channel arranged in the motor housing 2, and the liquid outlet 8 can be provided with one or more , arranged on the lower part of the motor front end cover 9 and / or the motor rear end cover 10 and / or the lower end of the motor housing 2, so that the oil is discharged from the inside of the motor after cooling and lubricating.

[0050] In this embodiment, the oil enters the motor cooling system through the liquid inlet 5, enters the main channel 7 of the liquid distribution channel through the liquid inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com